Tremie frame for marine bridge construction and platform construction process of tremie frame method

A construction technology and bridge construction technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as inapplicability, and achieve the effect of saving construction period, shortening construction time, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and the process implementation method.

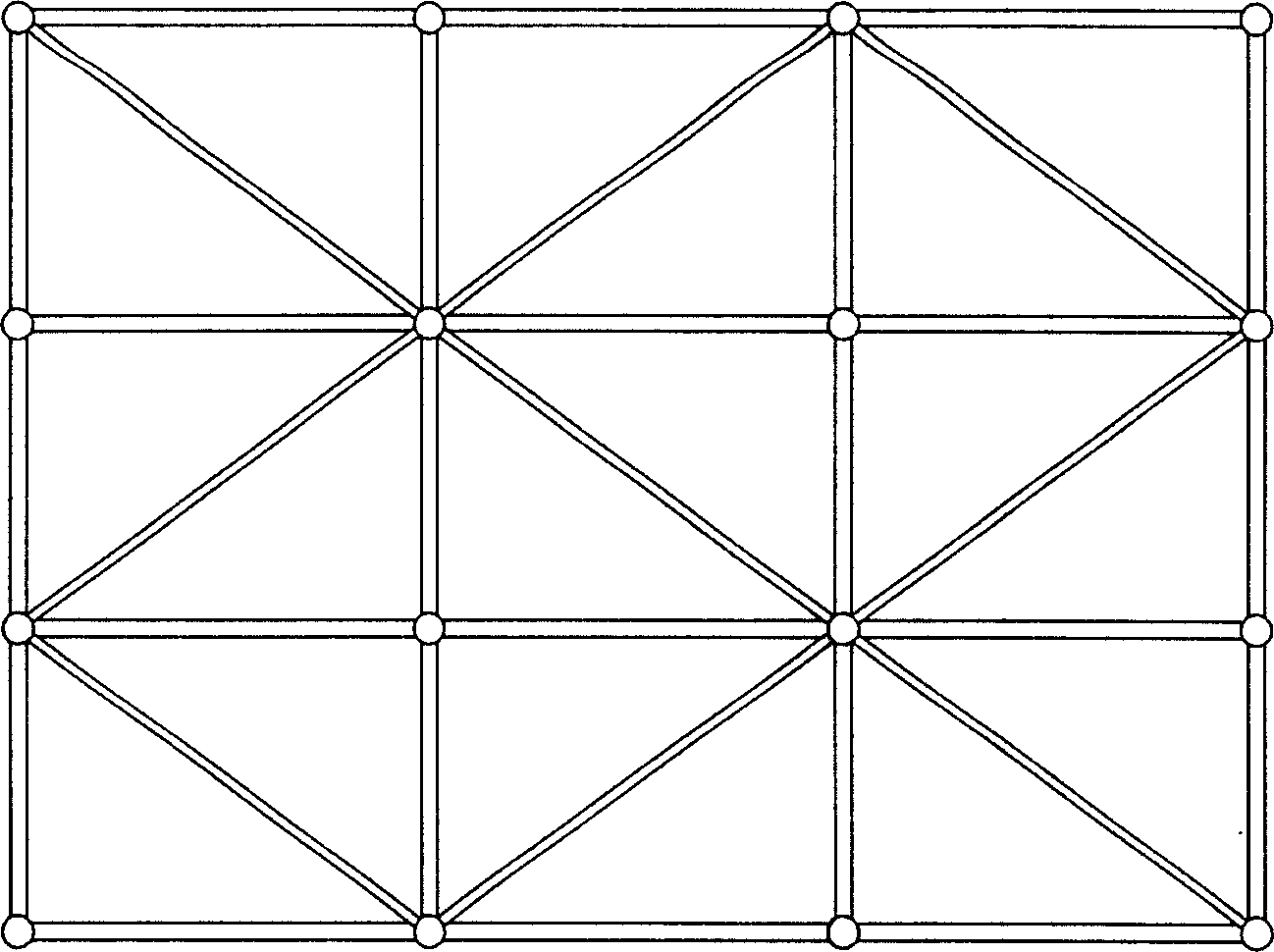

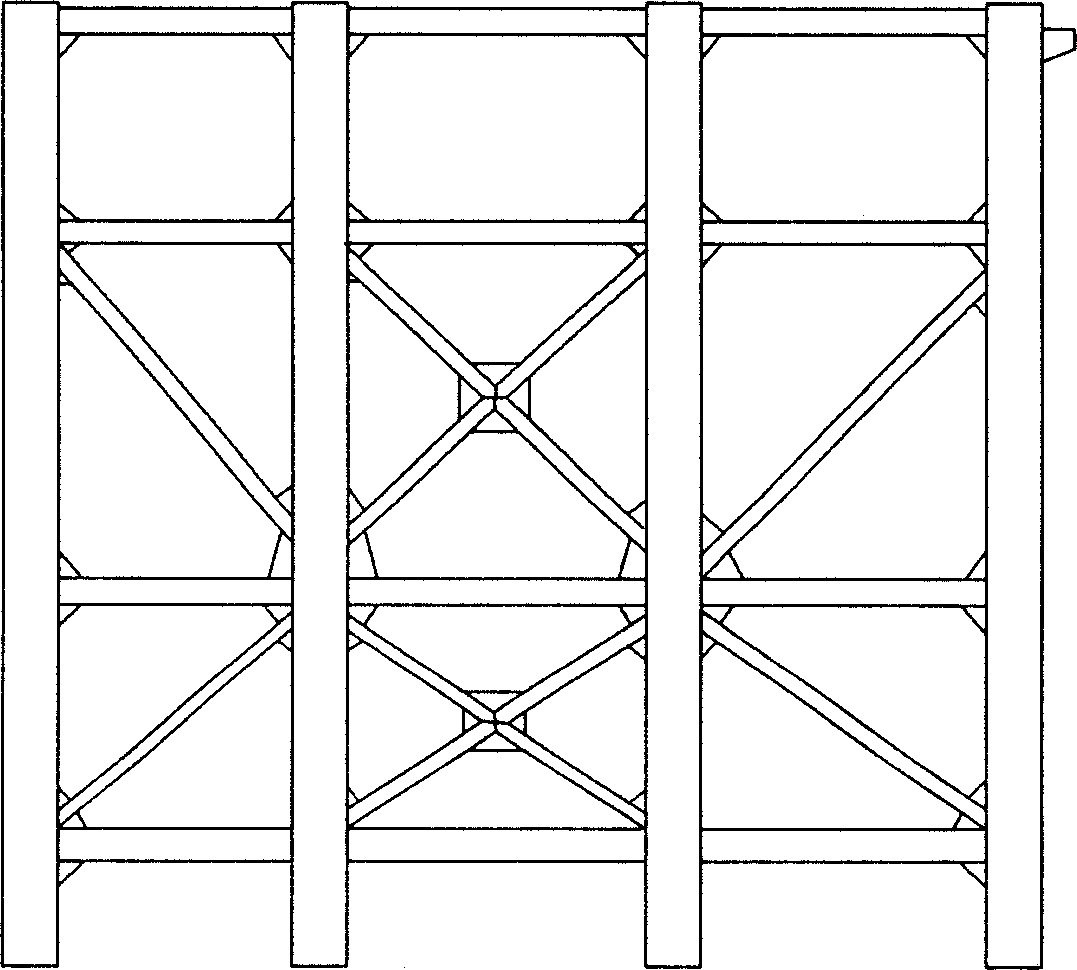

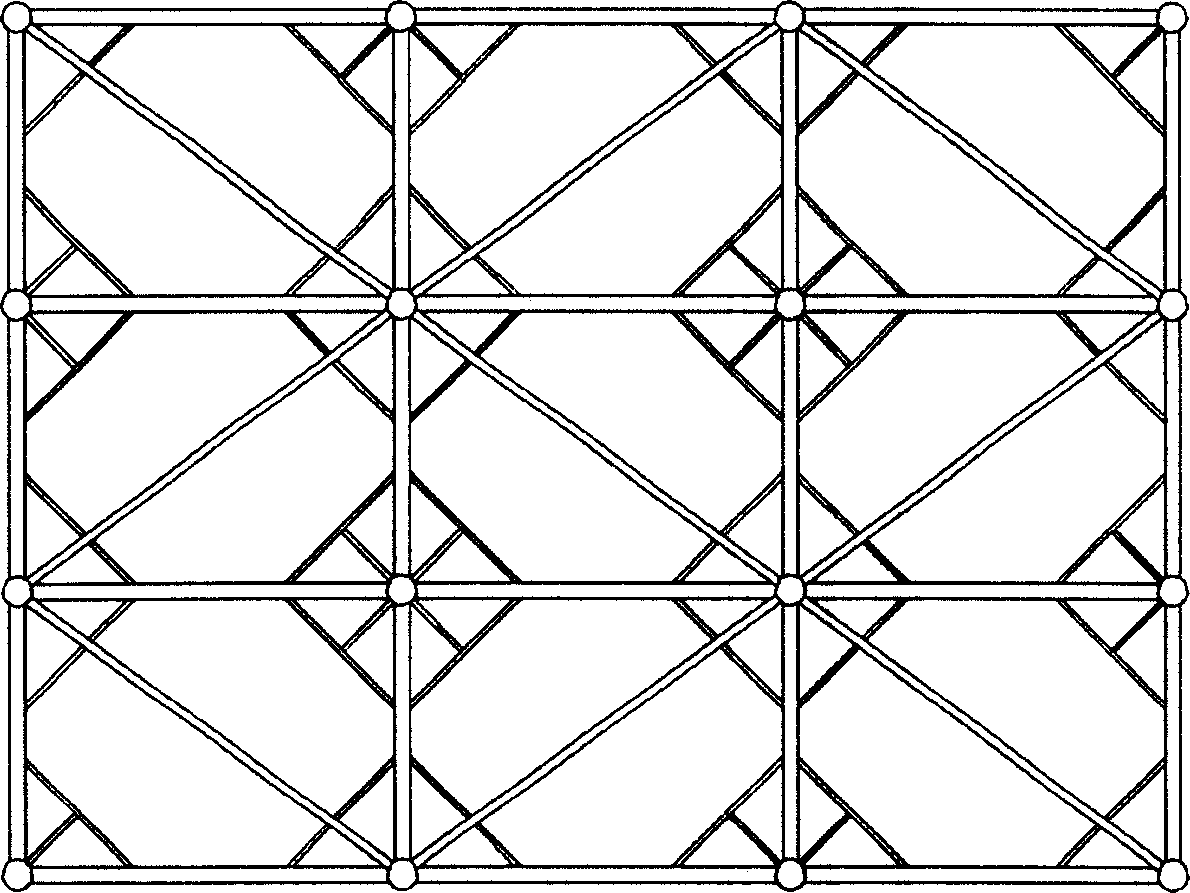

[0032] like Figure 1 to Figure 3 As shown, a jacket set up on the offshore construction platform of a cross-sea bridge has eight jackets in total. The main body of each jacket is composed of sixteen steel pipes with a diameter of 1 meter. There are four pipes between the sixteen pipes. The horizontal brace with a diameter of 0.4m and several diagonal braces with a diameter of 0.4m and 0.328m are connected as a whole. The jacket is 26.4m long, 18m wide, 19.2m high, and weighs about 285 tons. An anti-sinking plate is provided at the bottom of the jacket at 1.5 meters to prevent excessive sinking of the jacket under its own weight.

[0033] A jacket method platform construction process in the construction of a cross-sea bridge, the specific process steps are as follows:

[0034] (1) Fabrication and transportation of jacket:

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com