Single point anchor leg relaxation processing method

A treatment method, the technology of anchor legs, which is applied in the direction of warships, etc., can solve the problems of difficult control of construction progress, high cost of ships, and large impact, and achieve the effect of reducing release and tie-back work, reducing construction costs, and reducing construction risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention adopts the following operation steps:

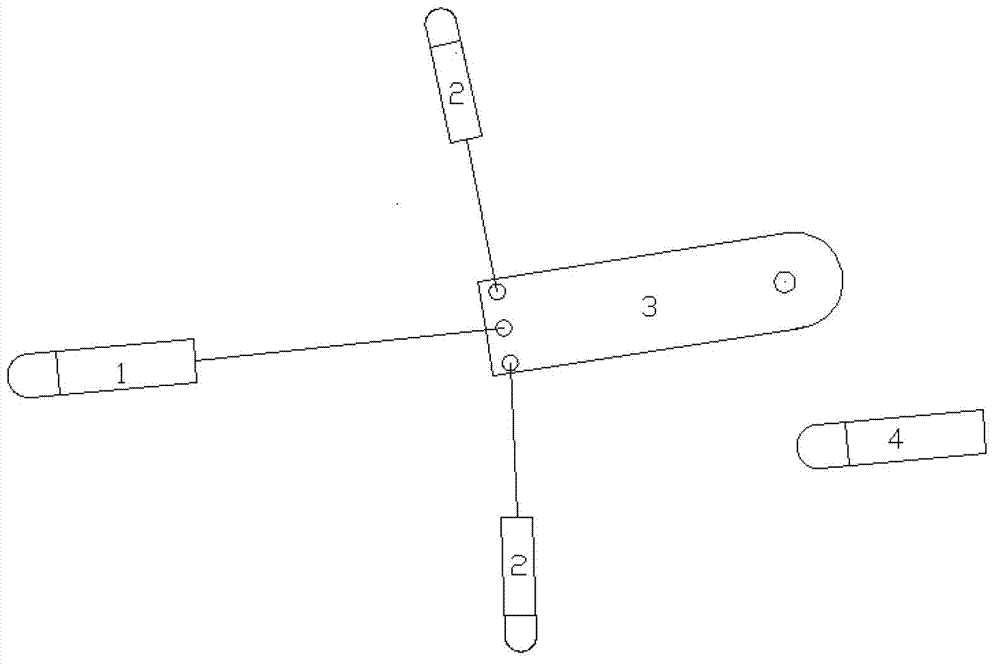

[0033] Step 1: At the offshore construction site—namely, several limit tugs are arranged around the floating production, storage and unloading tanker 3, and the heading of the offshore floating production, storage and unloading tanker 3 is controlled by the limit tugs;

[0034] Such as figure 1 As shown, at the offshore construction site—that is, several limit tugs are arranged around the floating production, storage and unloading oil tanker 3. In this embodiment, one main limit tug 1 and two auxiliary limit tugs 2 are arranged, and the limit tug The number and horsepower should be determined according to the size of the offshore floating production, storage and offloading tanker 3, and the tailing limit of the offshore floating production, storage and offloading tanker 3 by the limit tug is to limit the offshore floating production, storage and offloading tanker 3 in wind and waves. The rotation under the action ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com