Double-casing-pipe double-drive full-rotation type pile forming device and technology

A double-drive, double-casing technology is applied in the direction of casing, rotary drilling, rotary drilling rigs, etc., to achieve the effect of satisfying the construction depth, improving the hole forming efficiency and simplifying the construction operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

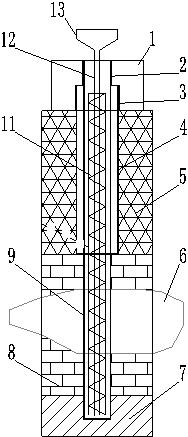

[0013] Such as figure 1 As shown, it is a structural schematic diagram of a double-casing double-drive full-rotation piling device of the present invention, including a double-casing double-drive full-rotary drilling rig 1, an upper clip 2, a lower clip 3, an outer casing 4, and an inner casing Pipe 9 and steel cage 11, double-casing double-drive azimuth drilling rig 1 is double-driven, with two sets of hydraulic drive systems, which are used to drive the upper clip 2 and lower clip 3 respectively, and are equipped with inner casings with different diameters 9 and outer sleeve 4. The lower clamping piece 3 is connected with the outer casing 4 , forward rotation can press the outer casing 4 to pass through the backfill layer 5 , and reverse rotation can pull the outer casing 4 out of the backfill layer 5 . The upper clip 2 is connected with the inner casing 9, and the forward rotation can press down the inner casing 9 to pass through the strongly weathered rock 8, the cave 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com