Preparation method of low-hydroxyl solid quartz steelyard weight

A quartz ingot, low hydroxyl technology, used in glass manufacturing equipment, manufacturing tools, glass molding and other directions, can solve the problems of low softening point, poor temperature resistance and high hydroxyl content of quartz products, and achieve low hydroxyl content and softening point. High and good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

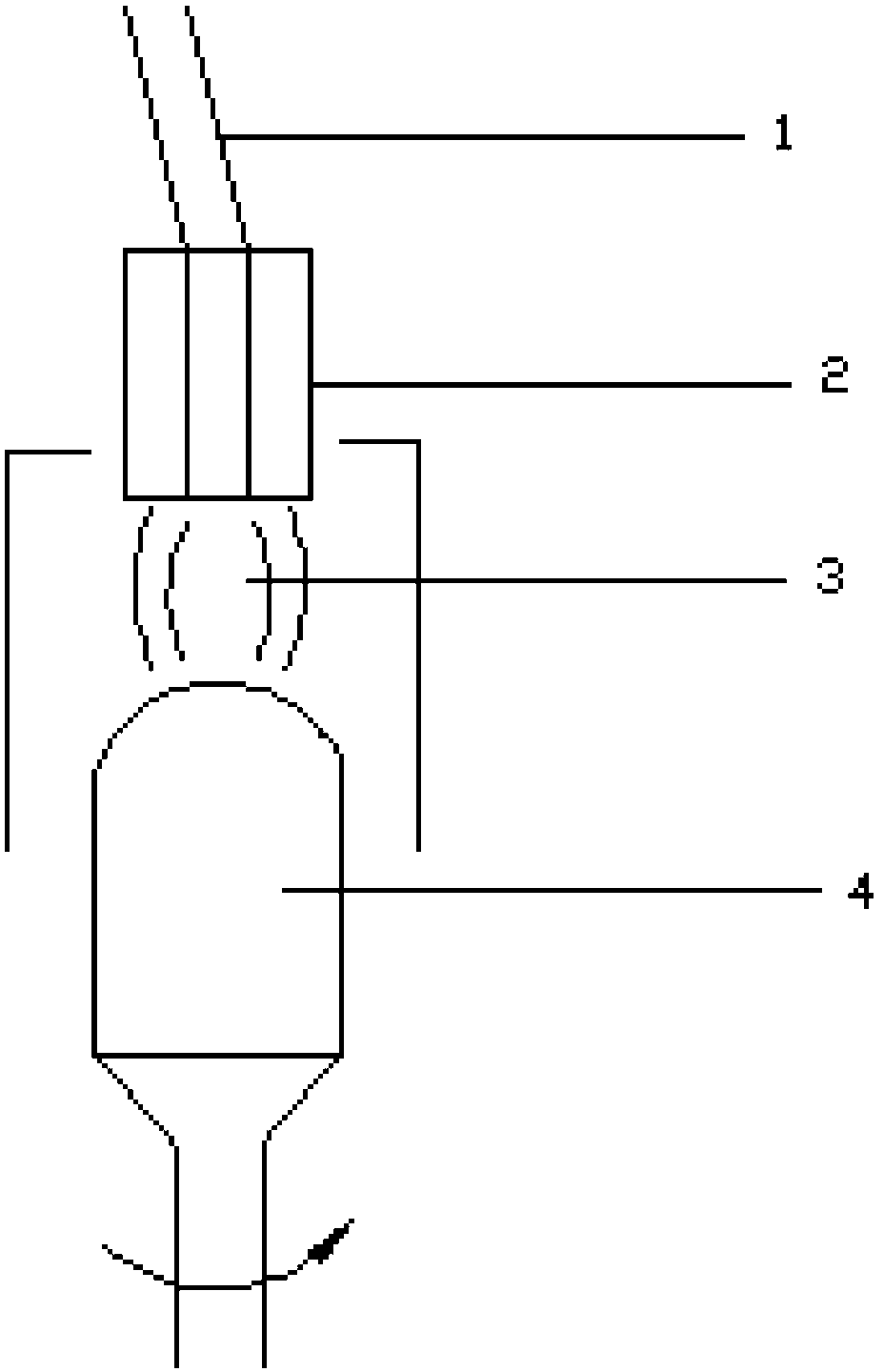

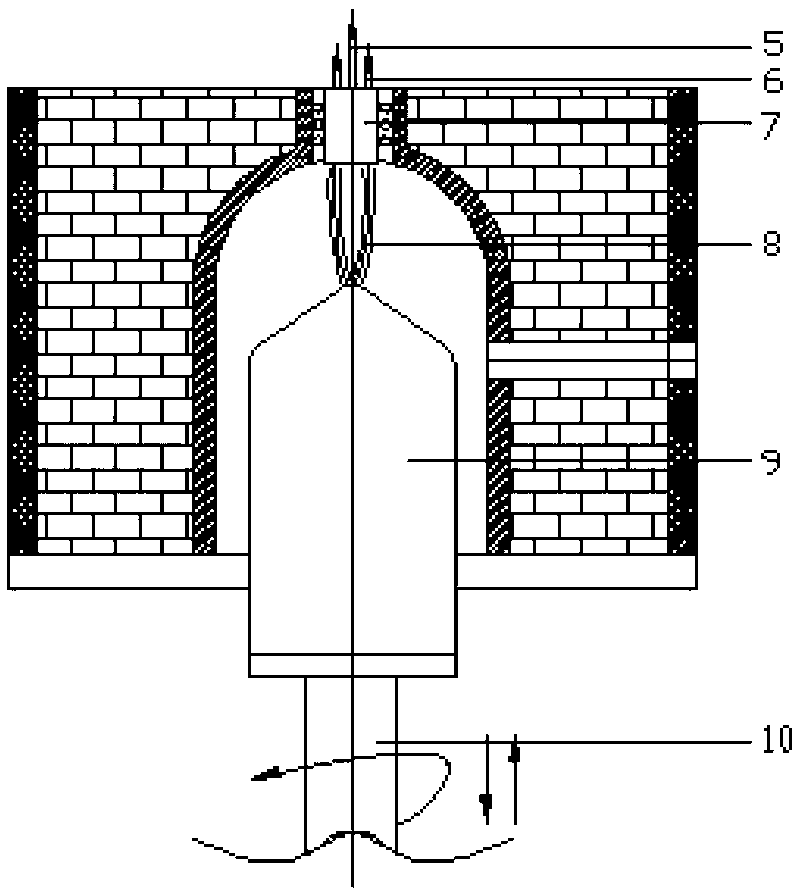

[0026] Embodiment 1: The flame generated by the plasma device is used as the heat source for melting quartz glass; the plasma device is placed on the top of the furnace, and the melting temperature, that is, the surface temperature of the quartz ingot is 1800°C to 2500°C.

[0027] Spray the quartz powder that enters the flame zone through the feeding tube onto the quartz glass target holder, and under the heating of the plasma flame, it will be continuously melted into a glass state, and the melt will start to accumulate on the target holder;

[0028] After the molten glass leaves the high temperature zone, it gradually cools down to become a columnar solid glass ingot. The top of the quartz glass target holder is located in the high temperature zone of the plasma flame. One side of the target holder rotates at a constant speed of 5 rpm, and the other side descends. The descending speed: 0.2mm / min, the feeding amount: 1.4kg / h, melting for 42 hours, and Ensure that the distance...

Embodiment 2

[0030] Embodiment 2: The flame generated by the plasma device is used as the heat source for melting quartz glass; the plasma device is placed on the top of the furnace, and the melting temperature, that is, the surface temperature of the quartz ingot is 1800°C to 2500°C.

[0031] The quartz powder is fed in from the central airflow of the plasma device, enters the flame zone, is sprayed onto the quartz glass target holder under the heating of the plasma, continuously melts into a glass state, and begins to accumulate melt on the target holder;

[0032] After the molten glass leaves the high temperature zone, it gradually cools down to become a columnar solid glass ingot. The top of the quartz glass target holder is located in the high temperature zone of the plasma flame. One side of the target holder rotates at a constant speed of 8 rpm, and the other side descends. The descending speed is 0.3mm / min, the feeding amount: 2.5kg / h, and is melted for 58 hours. Ensure that the di...

Embodiment 3

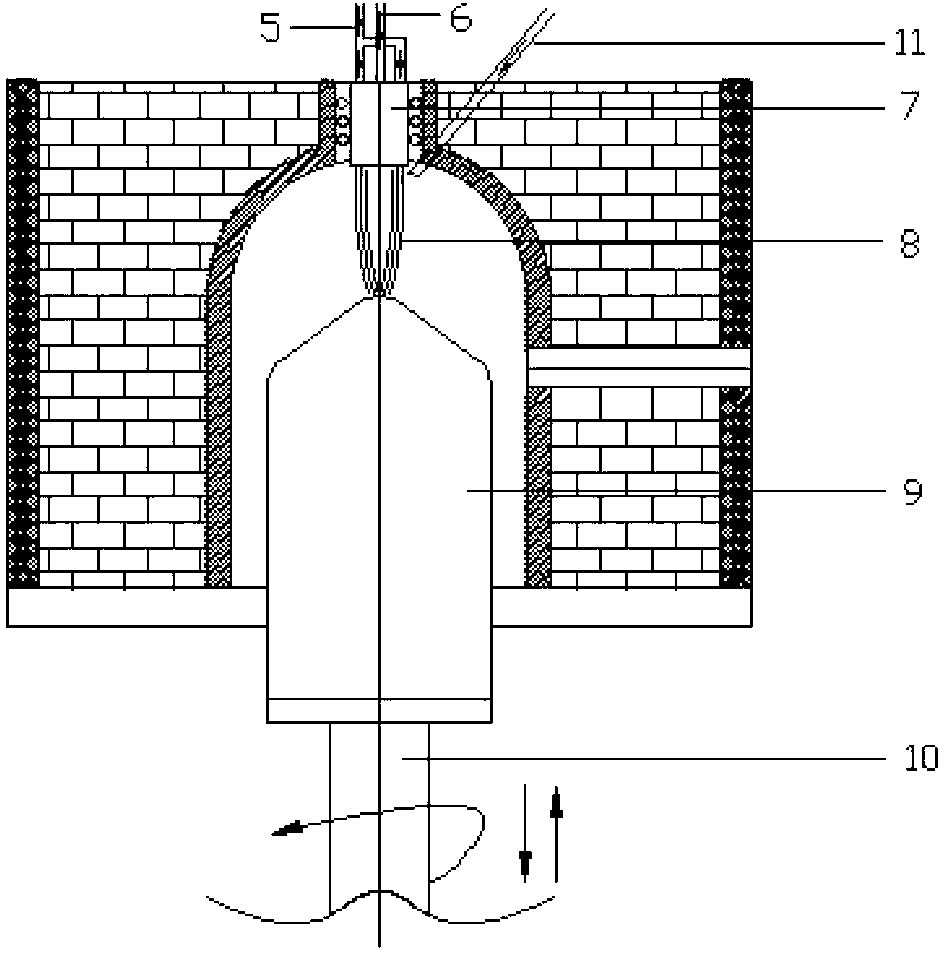

[0034] Embodiment 3: The flame generated by the plasma device is used as the heat source for melting quartz glass; the plasma device is placed on the top of the furnace, and the melting temperature, that is, the temperature on the surface of the quartz ingot is 1800°C to 2500°C.

[0035] Spray the quartz powder that enters the flame zone through the feeding tube onto the quartz glass target holder, and under the heating of the plasma flame, it will be continuously melted into a glass state, and the melt will start to accumulate on the target holder;

[0036] After the molten glass leaves the high temperature zone, it gradually cools down to become a columnar solid glass ingot. The top of the quartz glass target holder is located in the high temperature zone of the plasma flame. One side of the target holder rotates at a constant speed of 10 rpm, and the other side descends. The descending speed is 0.3mm / min, the feeding amount: 4.0kg / h, and is melted for 84 hours. Ensure that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com