Underwater separating type concrete pouring constructing method

A construction method and concrete technology, which is applied in the direction of construction and infrastructure engineering, can solve the problems of non-dispersion, poor quality of underwater pouring, easy to block pipe pouring, etc., achieve good dispersion resistance and fluidity, and reduce aggregate segregation , to avoid the effect of direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

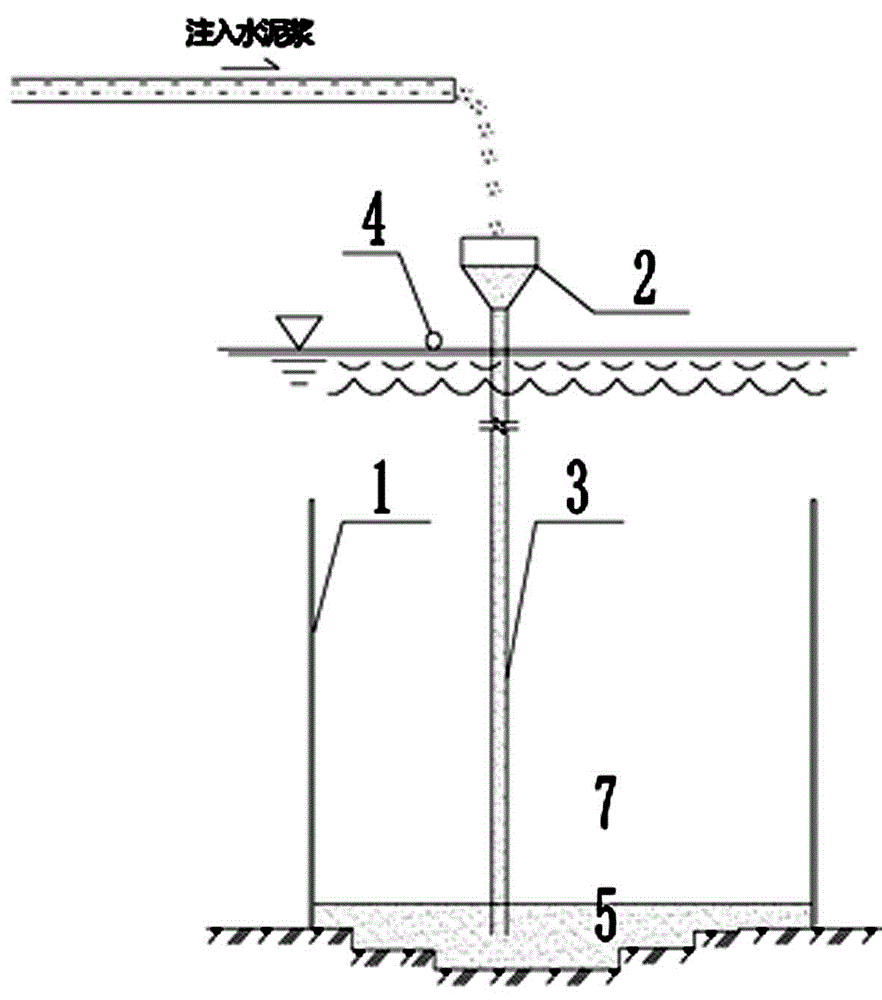

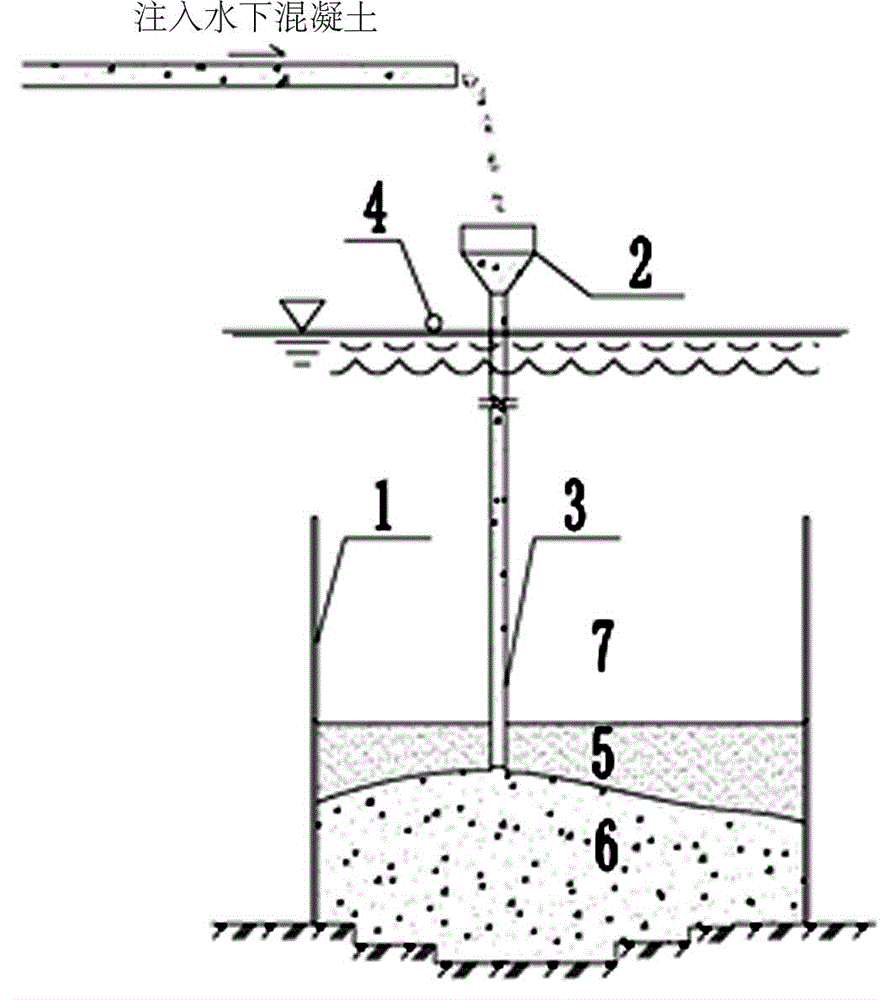

[0031] Cement slurry medium preparation: prepare a cement slurry medium with a specific gravity between water and concrete, homogeneous, viscous itself, but with good fluidity, as follows: the water-cement ratio of the cement slurry medium is 0.5-0.7 Between, density 1.6~1.7g / cm 3 . Add BT-7000 retarder to the cement slurry medium to control the initial setting time of the cement slurry to not less than 4 hours; add BT-7003 flocculant to the cement slurry medium to reduce cement slurry precipitation and increase the anti-dispersion of the cement slurry itself sex. In order to further prolong the retarding time of the medium and increase the homogeneity and fluidity of the medium, fly ash is added to the cement slurry medium. The fly ash grade is Class II. According to the equivalent replacement method, the dosage is 1 / 2 of the cement amount. 25%.

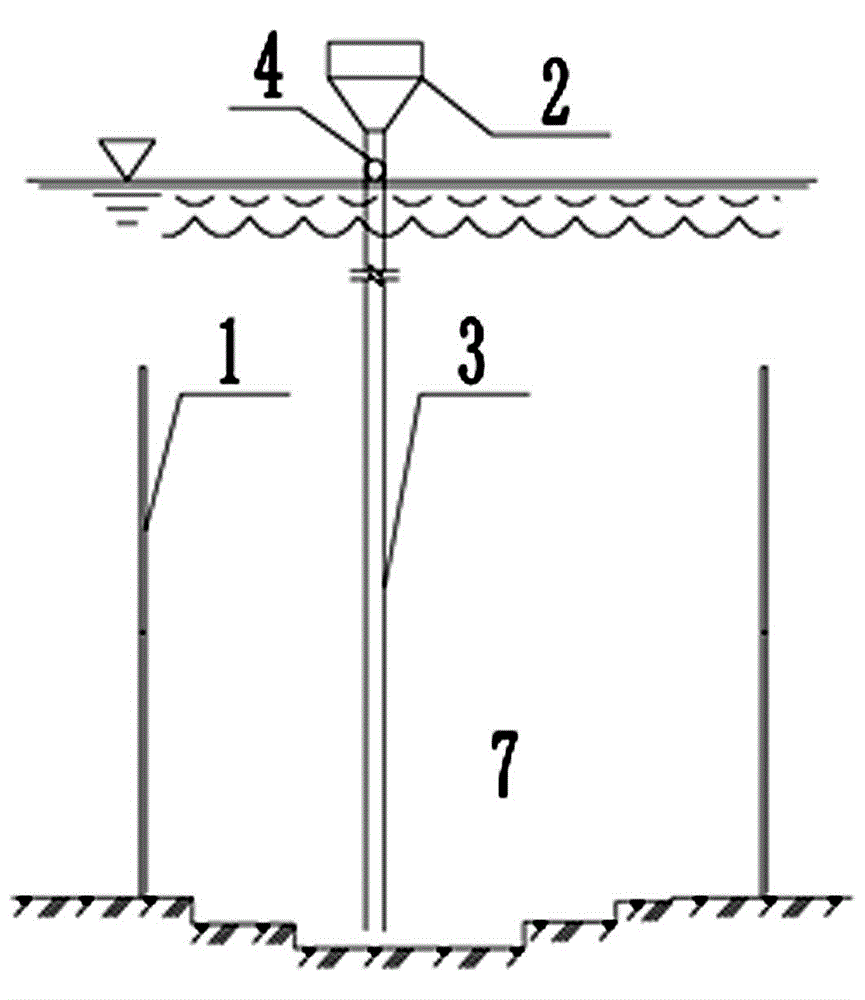

[0032] Construction steps: In the designated area for underwater pouring, under the condition that formwork 1 and grooves are r...

Embodiment 2

[0037] The following is a further detailed description of the present invention in conjunction with an example of underwater restoration of the apron end scoured downstream of a power station overflow dam in Hubei, but the implementation scope and method of the present invention are not limited thereto.

[0038] According to the underwater survey report, the stilling pool downstream of the overflow dam of the power station, the apron behind the pool, and the riverbed have experienced years of flooding during the flood season. The total length is 48m (such as Figure 5 ), the maximum scour height is 9m (compared to the original river bed surface), and the maximum scour depth of the apron foundation from the end of the apron to the upstream direction is 7m, thus forming an overhang at the end of the apron, and the hollowed out parts are all underwater. The depth range is 8-20m, and there are great potential safety hazards. According to the design plan, it is necessary to backfi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com