Feeding apparatus of cylinder drier

A feeding device and drying machine technology, applied in non-progressive dryers, dryers, drying, etc., can solve the problems of large feeding resistance, long feeding distance, easy blockage, etc., to reduce the feeding resistance , not easy to stick and block, and the effect of long use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

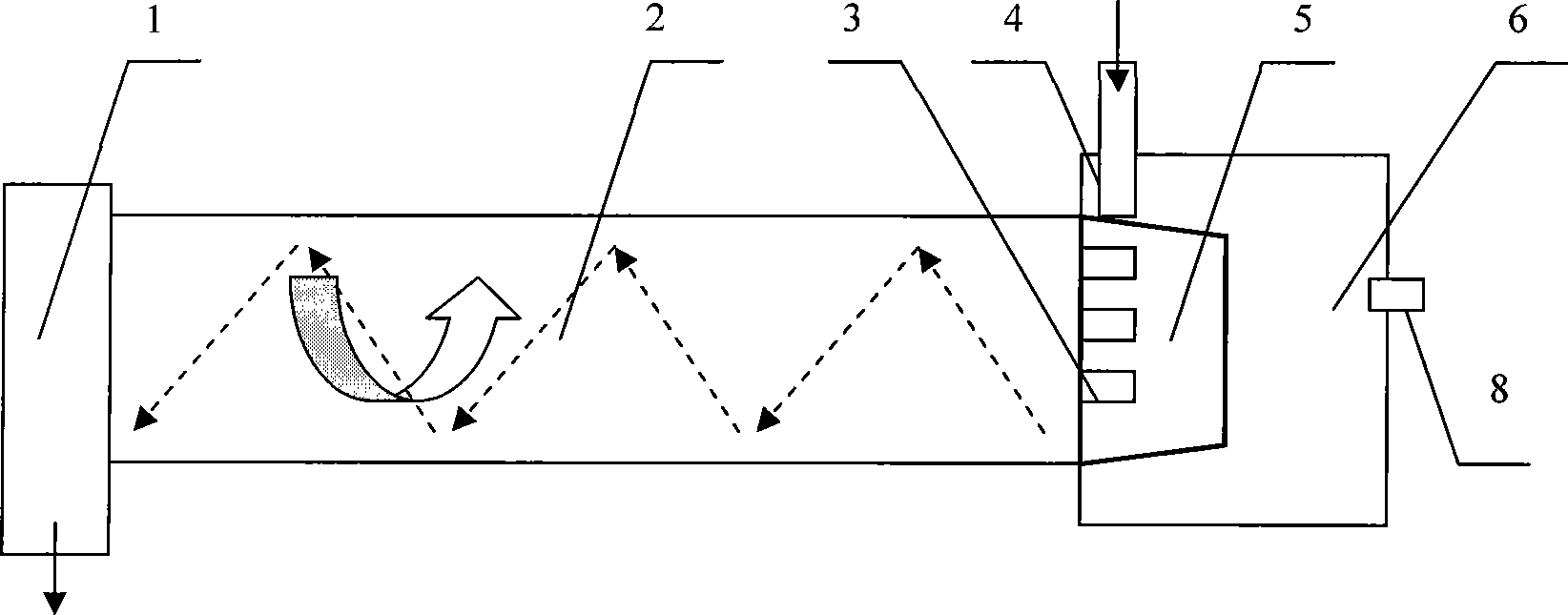

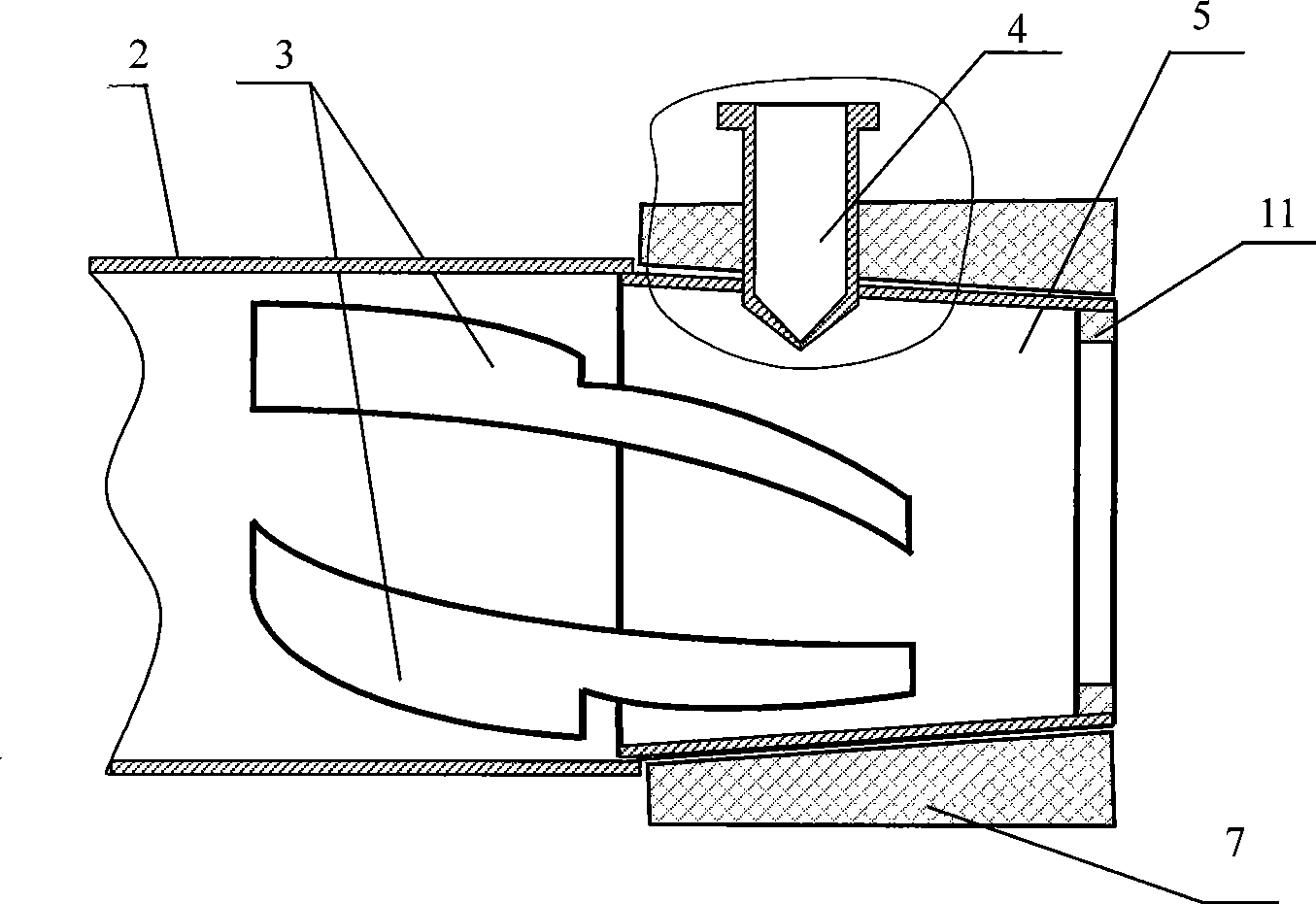

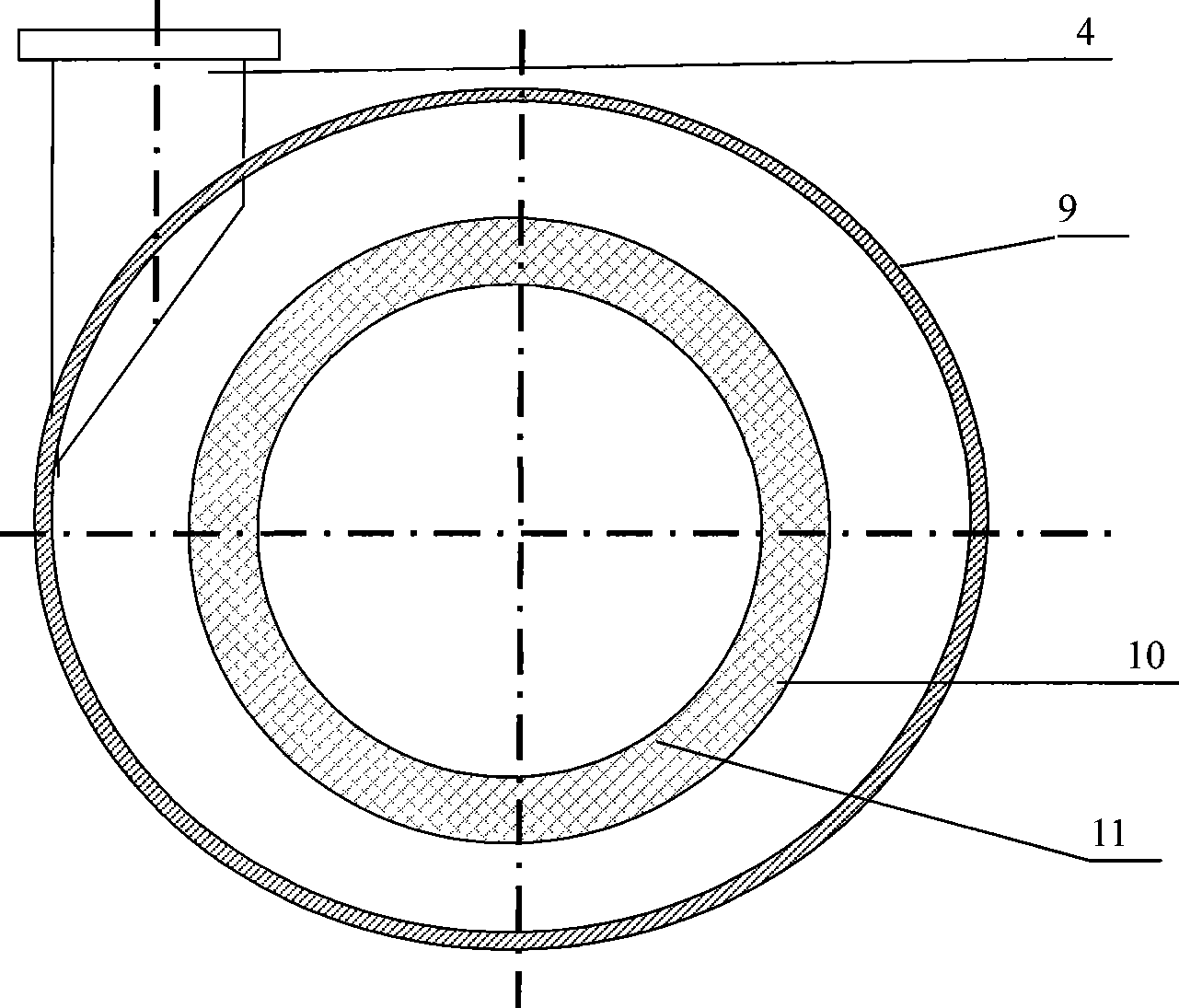

[0024] A feeding device for a cylinder dryer, such as Figure 1 to Figure 4 As shown, it is arranged between the combustion chamber 6 of the cylinder dryer and the rotary kiln cylinder 2. The other end of the cylinder 2 is the discharge end 1, which is coaxially connected with the combustion chamber 6 and the cylinder 2. It includes material It is the blanking pipe 4, the fixed cylinder 5 and the inclined plate 3 of the boiler steel. The fixed cylinder 5 is made of a 25mm steel plate and rolled into a conical horn body. The outer surface of the fixed cylinder 5 is built with a refractory material 7, and the refractory material 7 is refractory. Concrete, the fixed cylinder 5 is fixed in the combustion chamber 6 and its large open end is suspended into the cylinder 2, and the length of the extension into the cylinder 2 is 50mm. The small end of the fixed cylinder 5 is provided with an annular stopper ring 11, and the feeding pipe 4 is made of 6mm steel plate with a diameter of 3...

Embodiment 2

[0026] A feeding device for a cylinder dryer, such as Figure 1 to Figure 4 As shown, it is arranged between the combustion chamber 6 of the Φ2.4m×18m cylindrical dryer and the rotary kiln cylinder 2. The other end of the cylinder 2 is the discharge end 1, which is coaxial with the combustion chamber 6 and the cylinder 2. Connection, it includes a stainless steel feeding pipe 4, a fixed cylinder 5 and an inclined plate 3. The fixed cylinder 5 is made of a 20mm steel plate rolled into a conical horn body, and the outer surface of the fixed cylinder 5 is built with a refractory material 7. The material 7 is refractory concrete, the fixed cylinder 5 is fixed in the combustion chamber 6 and its open big end is suspended into the cylinder 2, and the length of the fixed cylinder 2 is 200mm. The small end of the fixed cylinder 5 is provided with an annular stopper ring 11, and the feeding pipe 4 is made of 6mm steel plate with a diameter of 360mm, and is vertically installed on the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com