Installation Of Ground Loops For Geothermal Heating And/Or Cooling Applications

a technology for installing ground loops and geothermal heating and/or cooling applications, which is applied in the direction of sealing/packing, lighting and heating apparatus, and well accessories. it can solve the problems of voids, more difficult, and difficult to take ground loops or heat exchangers down into the borehol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Overview

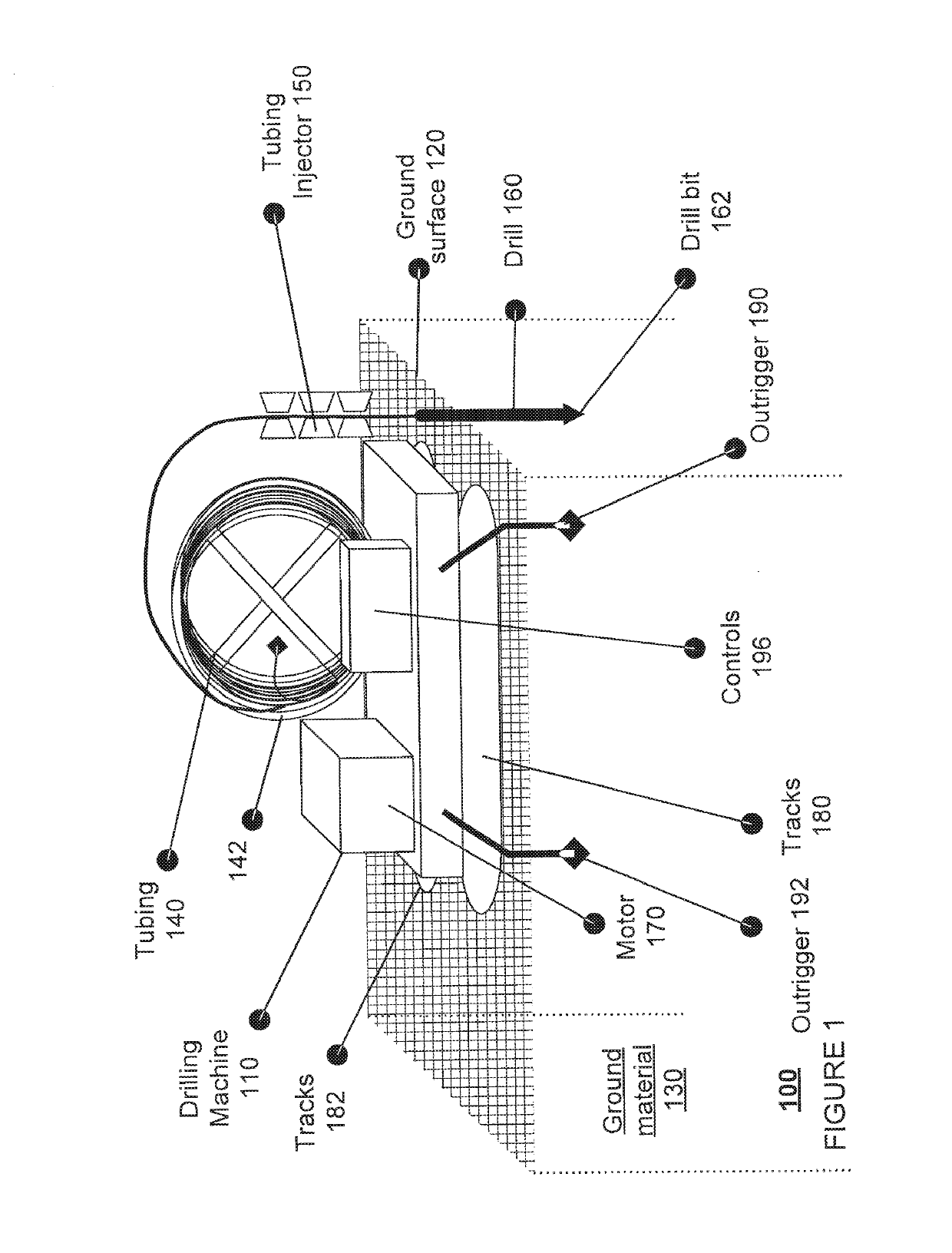

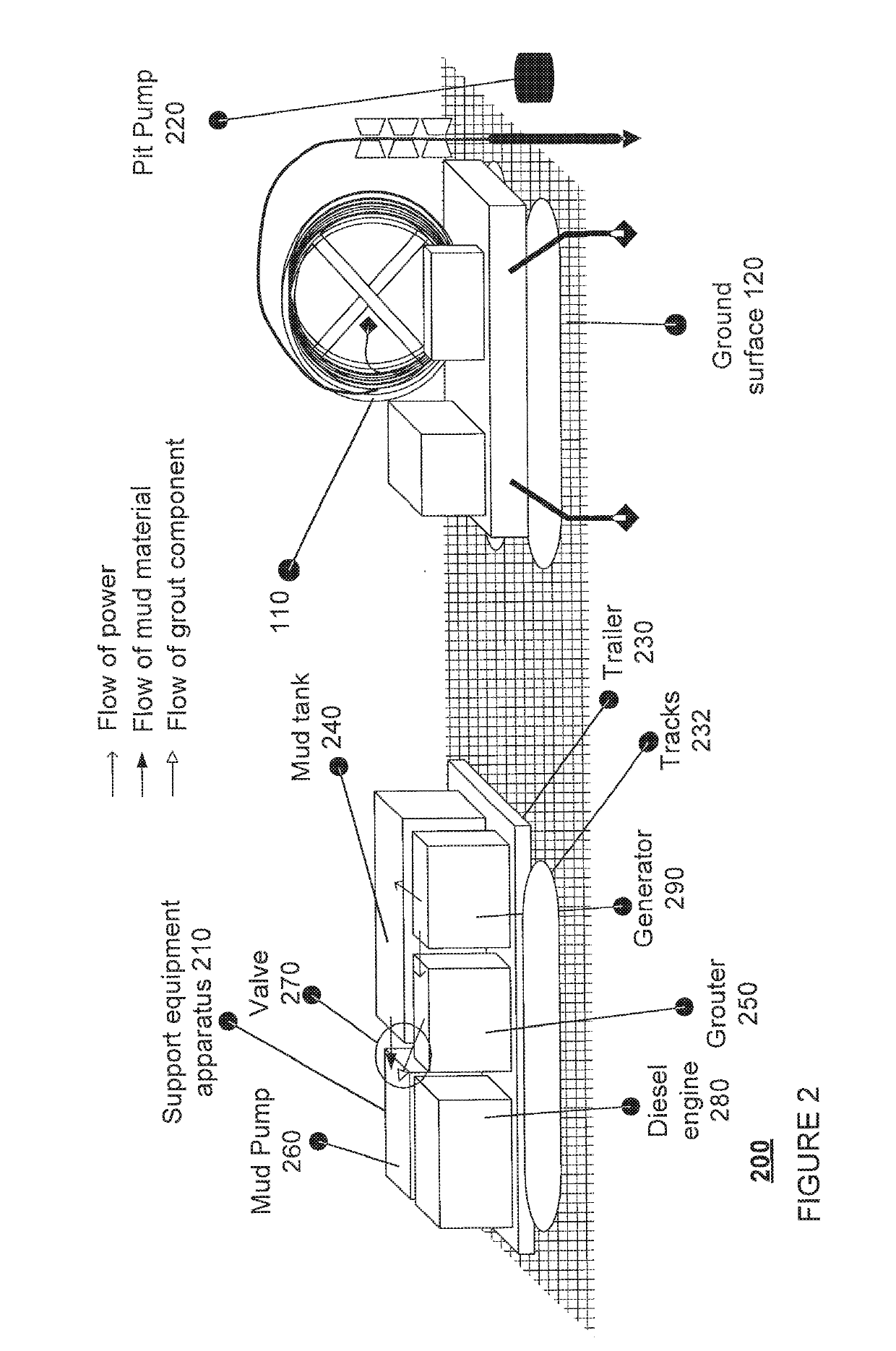

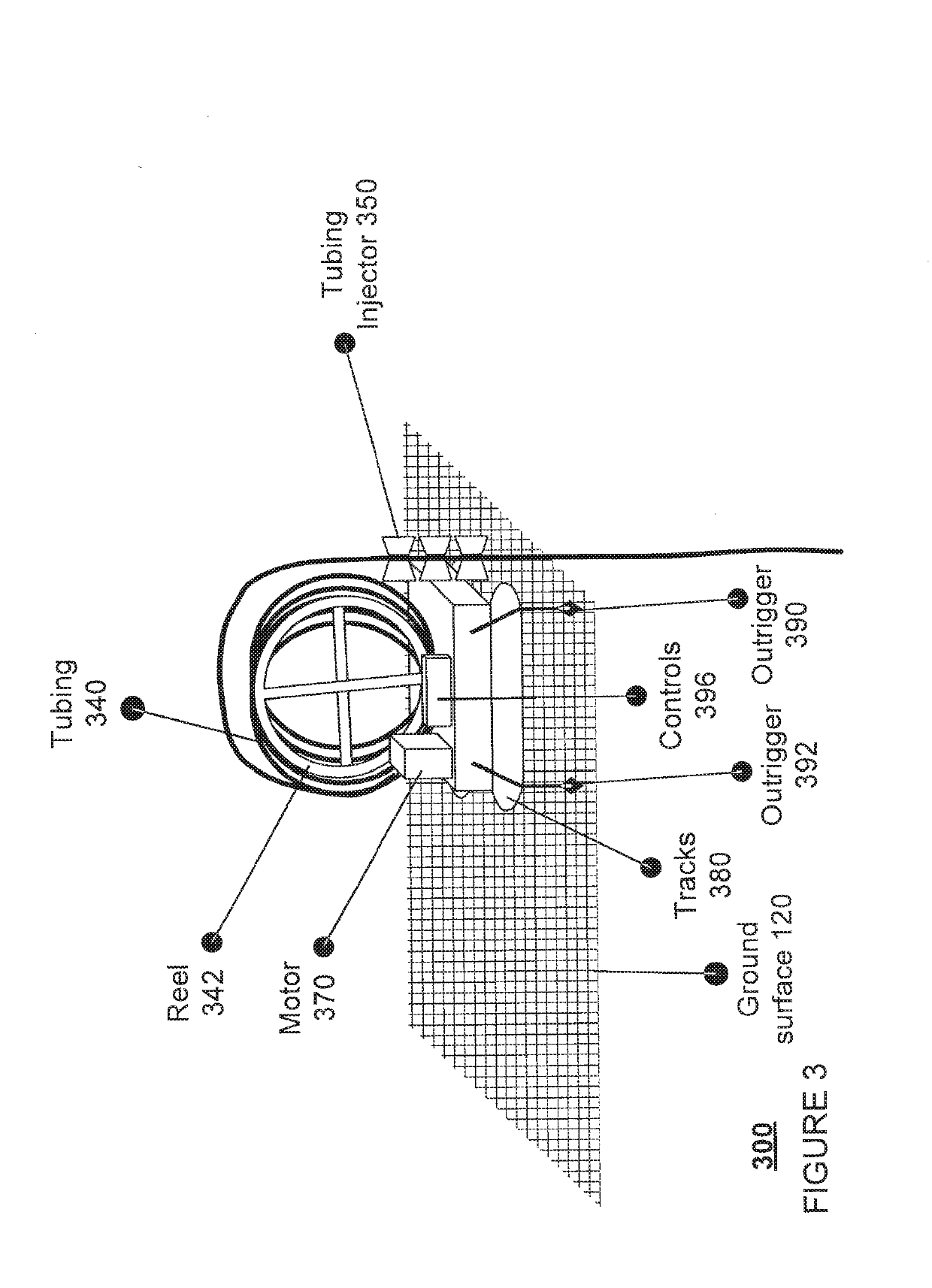

[0020]Aspects of the technology relate installing a ground loop for a geothermal heating and / or cooling system, such as those used to heat and cool various structures. For instance, an example system may include a drilling machine, an equipment support apparatus, and a heat exchanger insertion apparatus. The drilling machine may include a coil of tubing. A first end of the tubing may be configured with a drill such as a downhole drilling mud motor or downhole hammer with an attached drill bit. The drilling machine may also include or be connectable with a tubing injector which can be clamped around the tubing in order to straighten the tubing and to orient the tubing into a borehole created by the hammer.

[0021]The drilling machine also includes a drive system configured to control the extension and retraction of the tubing. In this regard, the drive system may rotate a reel upon which the tubing is wrapped. The drive system may also control movement of the drilling machine, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com