Winding tube type heat exchanger with circular tube flow guider and inner lining barrel device

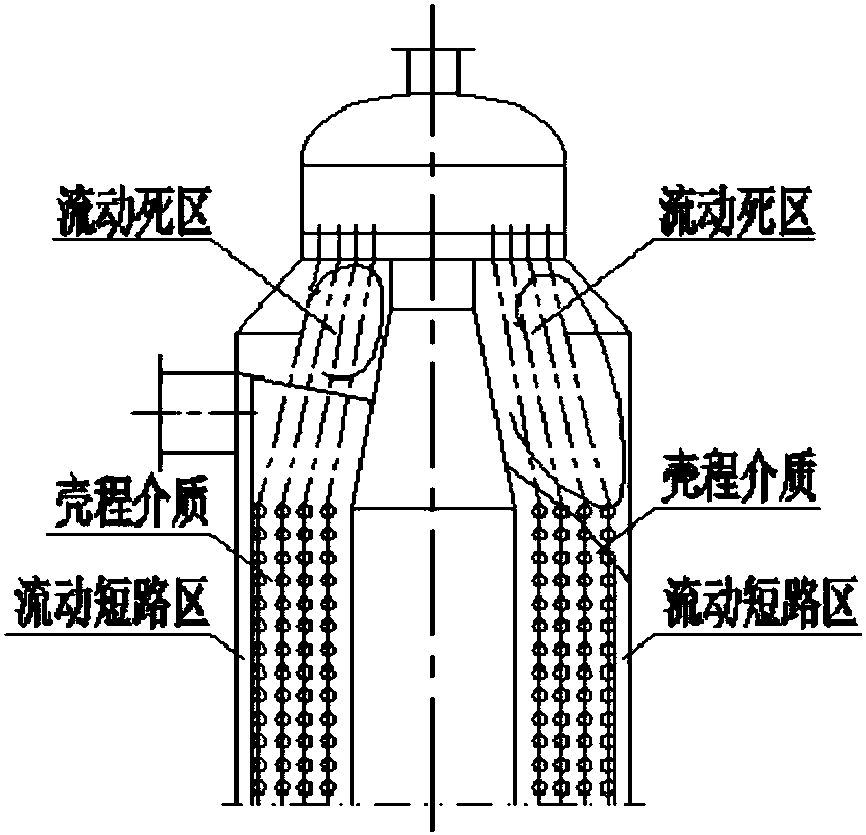

A winding tube type, lined tube technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of improving, affecting heat exchange efficiency, large flow dead zone, etc., to expand the medium flow area, improve heat exchange efficiency, and reduce the effect of medium flow dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

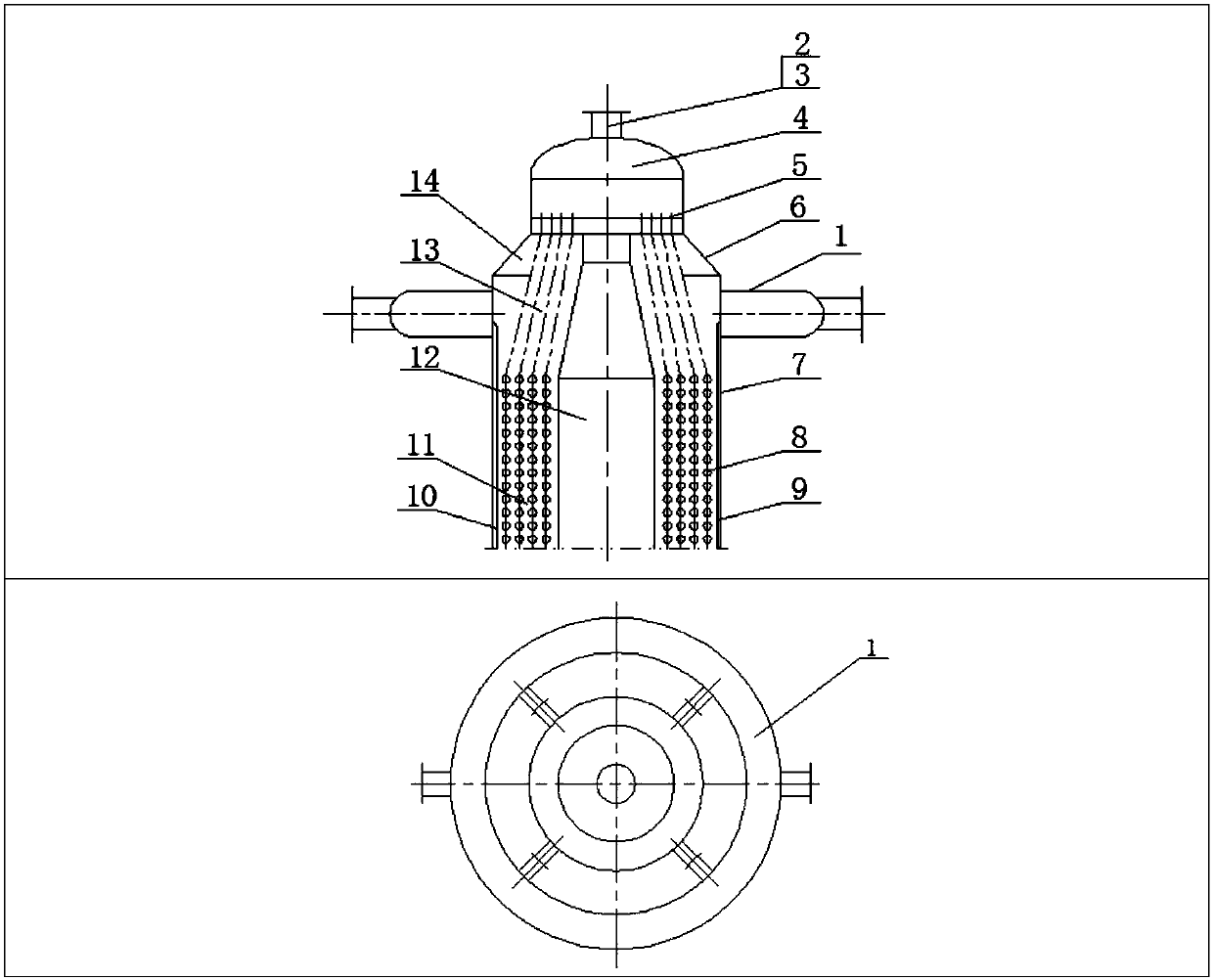

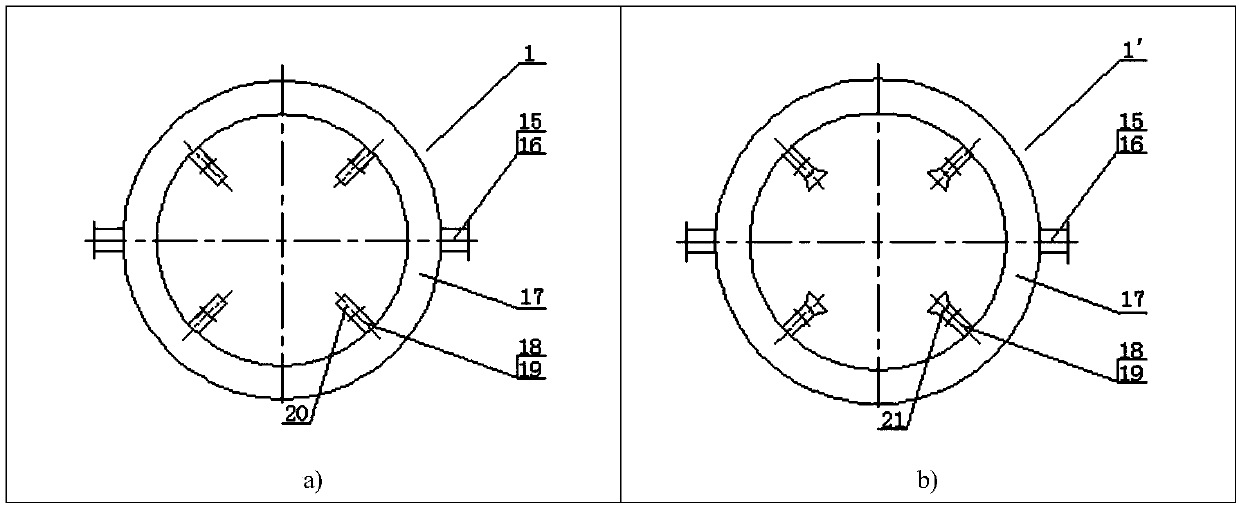

[0038] Such as figure 2 , image 3 a), Figure 4-7 shown.

[0039]A coiled tube heat exchanger with a ring tube deflector and an inner liner device, which includes a tube box 4, a tube sheet 5 and a shell-side cylinder 7, the tube box 4 is connected with a head, and the tube sheet 5- One side is connected to the tube box 4, and the other side is connected to the shell-side conical tube section 6. A core tube 12 that runs through the entire heat exchanger is installed in the shell-side tube 7, and heat exchange tubes 8 are installed around the core tube 12. And in the inner and lower part of the process cylinder 7, a coiled tube heat exchange zone 11 is formed, and a straight tube transition zone 13 is formed between the tube sheet 5 and the tube coiled zone 11, which is characterized in that the shell-side cylinder corresponding to the straight tube transition zone 13 The outer side of the body 7 is equipped with a circular pipe deflector 1, which communicates with the rea...

Embodiment 2

[0044] Such as image 3 b), Figure 4 , Figure 8-11 shown.

[0045] Such as Figure 8 As shown, the difference between the present embodiment and the first embodiment is that a trumpet-type annular tube deflector 1' and an inner liner 10 are installed in the heat exchanger, and the tube-side connecting pipe 2 and the pipe-side connecting pipe are arranged on the head of the pipe box 4 Flange 3, one side of tube sheet 5 is connected to tube box 4, and the other side is connected to shell-side conical barrel section 6. There is a straight tube transition area 13 between tube sheet 5 and tube winding area 11, and the straight tube transition area 13 and There is a transitional cavity area 14 between the shell-side conical cylinder section 6 and the shell-side cylinder 7 , and a flow stagnation zone 9 exists between the inner liner 10 and the shell-side cylinder 7 .

[0046] Such as image 3 As shown in b), the horn tube type annular tube deflector 1' comprises an inlet flan...

Embodiment 3

[0054] The difference between this embodiment and Embodiments 1 and 2 is that the entire heat exchanger only adopts the annular pipe deflector 1 to reduce the flow dead zone, and does not install the inner liner at the lower part of the shell cylinder, which can also significantly improve the heat transfer. Efficiency, but higher heat loss. This scheme can be used as appropriate according to the heat loss situation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com