Grid type supporting baffling device of shell-and-tube heat exchanger

A shell-and-tube heat exchanger, heat exchanger technology, applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve the problem of inability to achieve effective support, difficult tube bundle assembly, and long span of baffle rods and other problems, to achieve the effect of increasing material and processing costs, reducing equipment processing volume, and reducing equipment weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

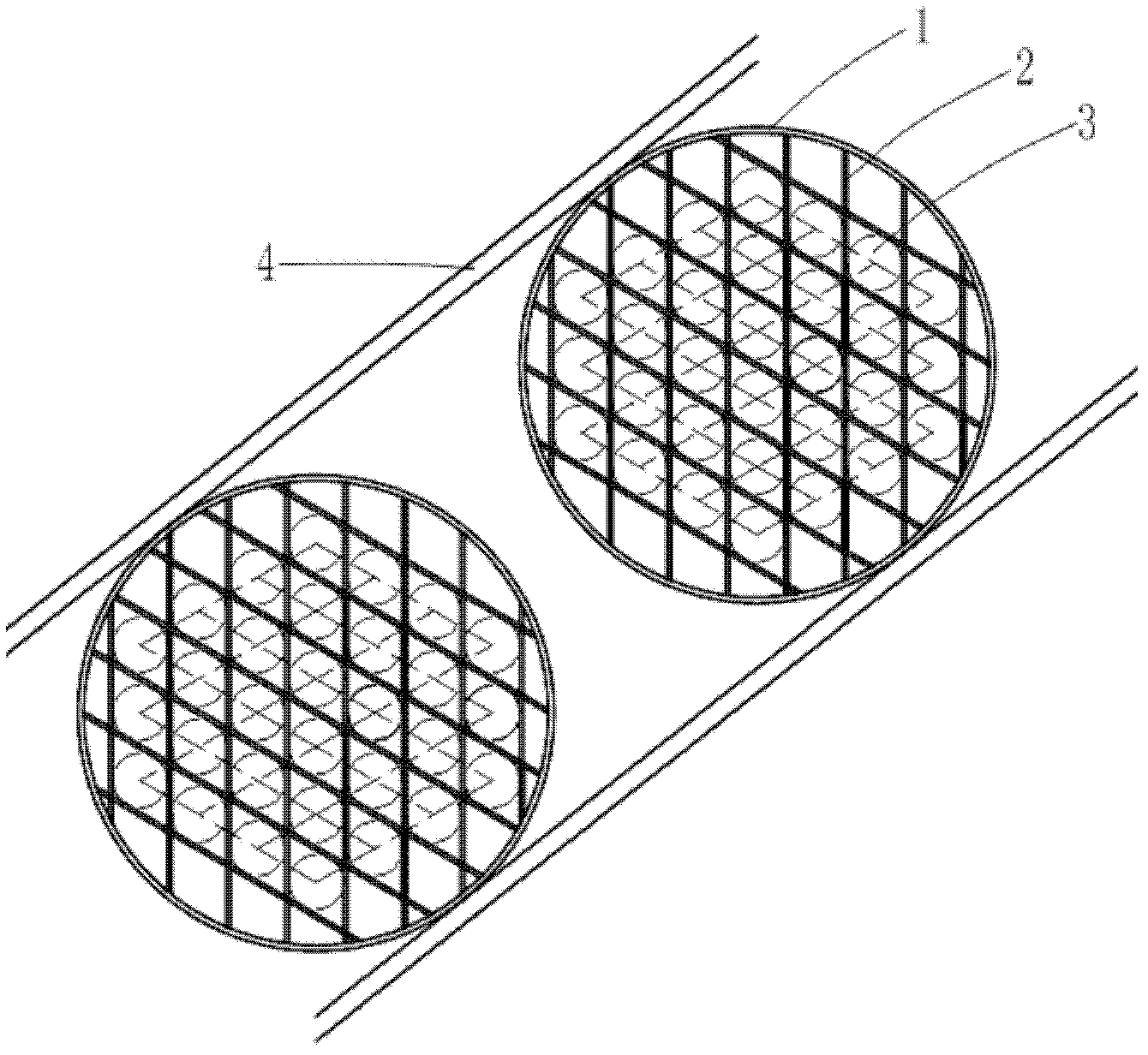

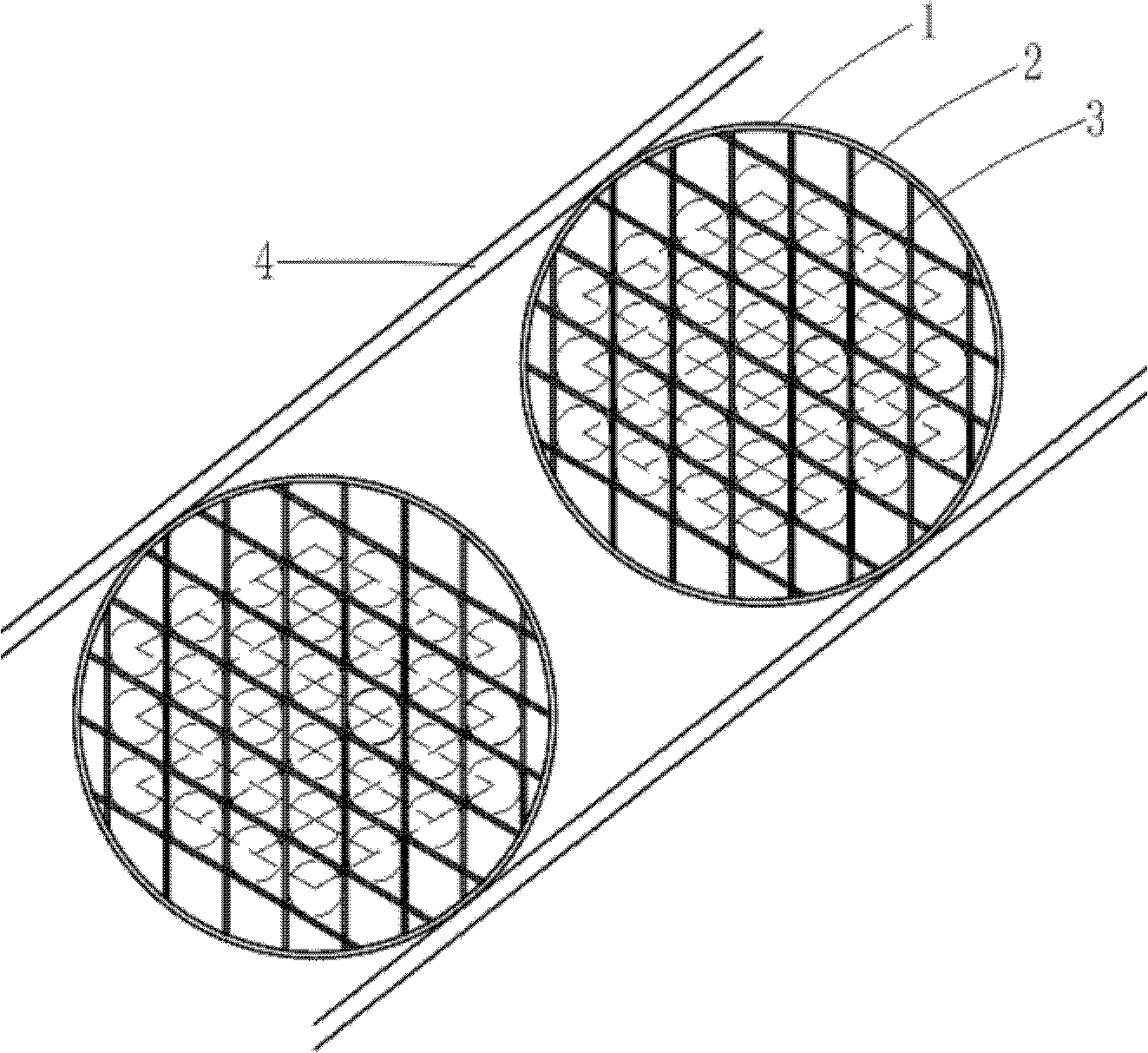

[0022] Example: Combine figure 1 , 2 , the grid-type supporting baffle device of the shell-and-tube heat exchanger of this embodiment, which includes: a support limiting ring 1 welded and fixed to the inner wall of the heat exchanger shell 4, and a plurality of grids are arranged in the supporting limiting ring 1 The grid plates 2 are cross-connected to form a porous grid network. The heat exchange tubes 3 pass through the holes of the grid network and the outer walls of the heat exchange tubes 3 are in close contact with the inner walls of the holes. The two ends of each grid plate 2 are bounded by the support. The inner wall of the ring 1 is fixed by welding. The holes are rhombus holes or square holes.

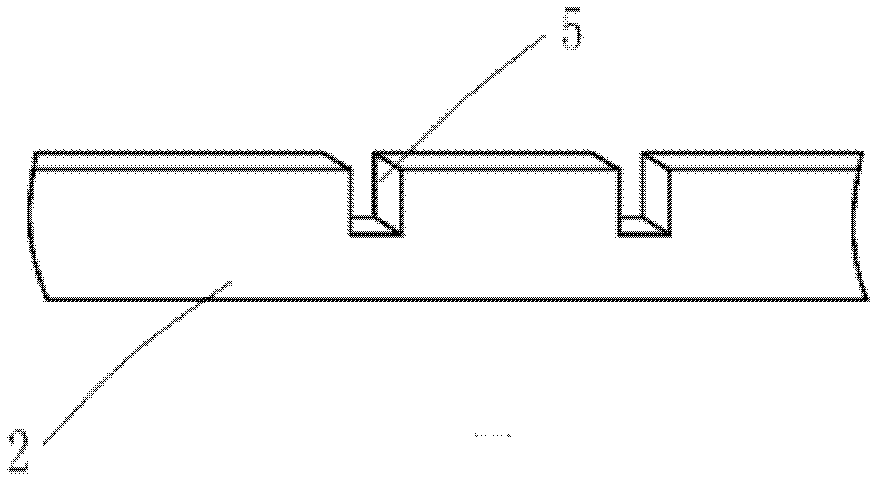

[0023] In specific settings, figure 2 As shown, each grid plate 2 is provided with open slots 5, and any two intersecting grid plates are plugged into each other through the slots and the intersection points are welded and fixed. The center-to-center distance L between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com