High-efficiency scaling turbolator ring pipe frame and heat exchanger with same

A turbulent, high-efficiency technology, applied in the field of heat exchangers and their components, can solve the problems that affect the effective heat exchange area of the heat exchanger, the fluid flow resistance of the shell side is large, and the structure of the heat exchange tube is complicated, and the structure is simple. , The effect of improving the average heat transfer temperature difference and reducing the flow dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

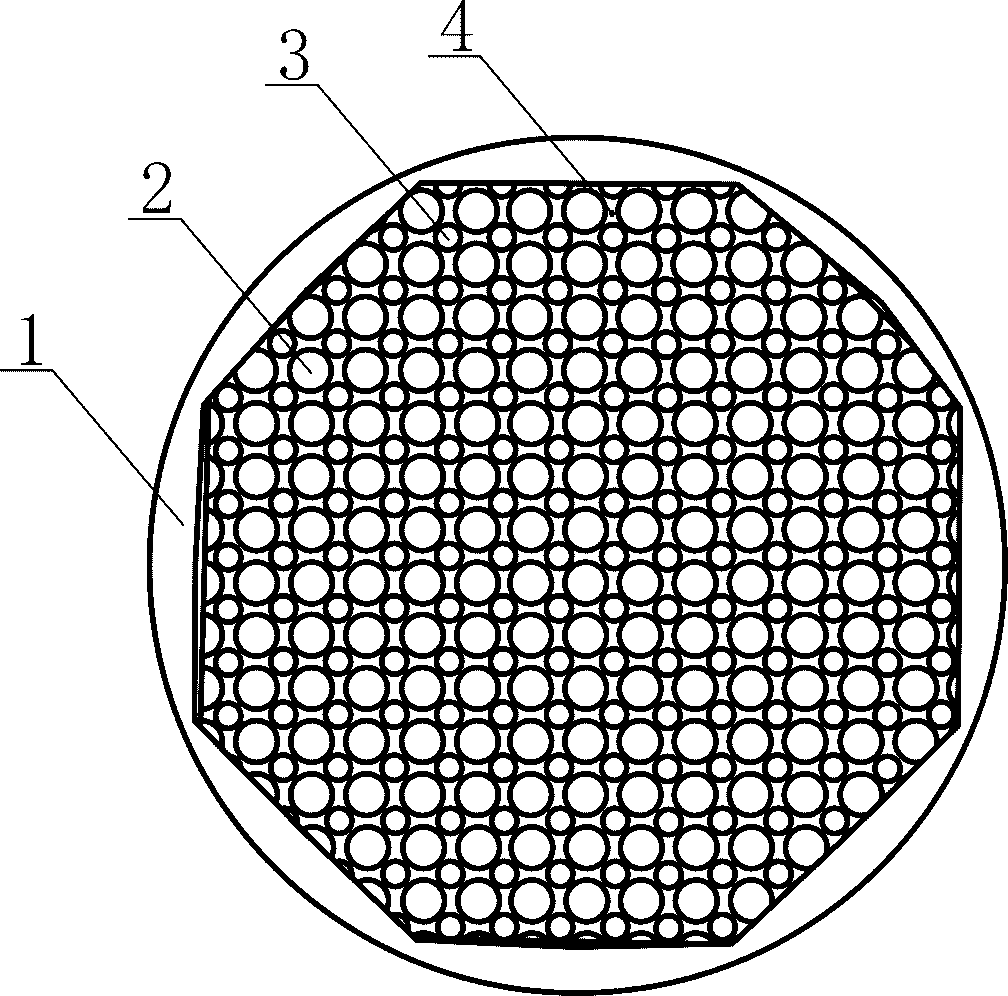

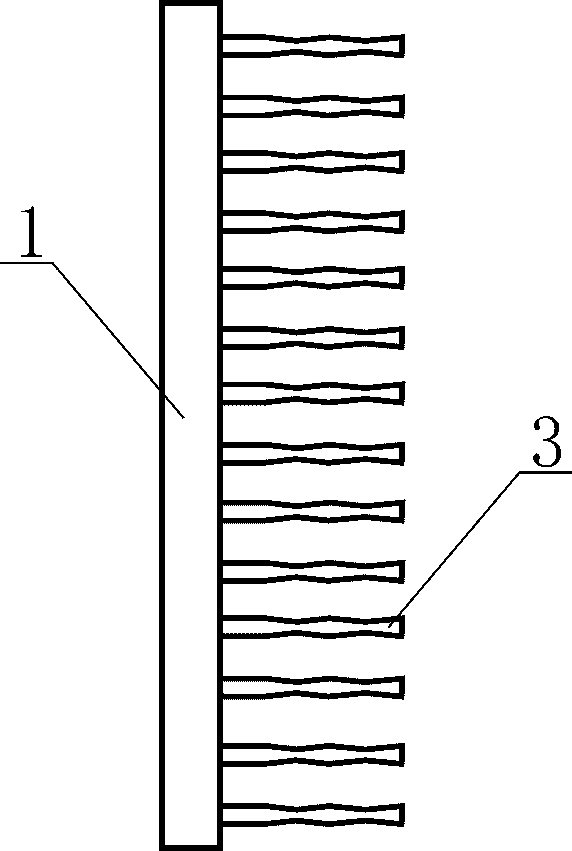

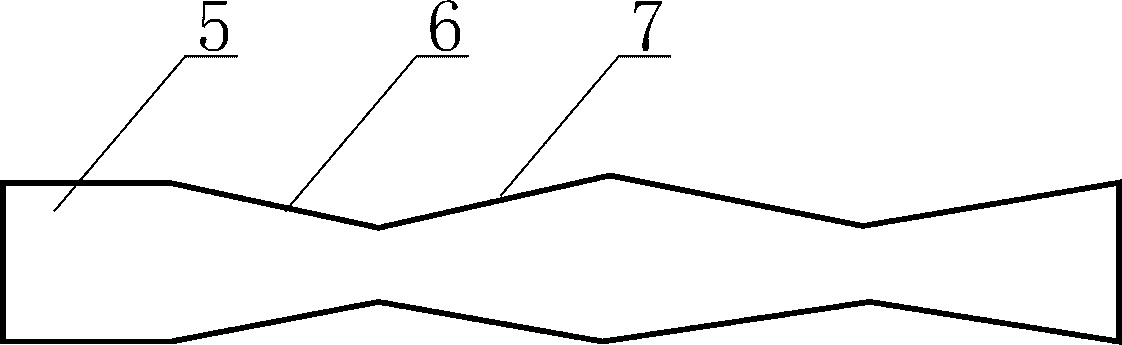

[0025] Such as figure 1 , 2 As shown in , 3, the high-efficiency scaling spoiler annular tube frame is mainly composed of a fixed ring 1, a plurality of annular tubes 2 and a plurality of scaling spoilers 3, and a plurality of annular tubes 2 and a plurality of scaling spoiler 3 Fixed in the fixed ring 1, the ring pipes 2 are horizontally arranged in a row and distributed at intervals, the ring pipes 2 are arranged in multiple rows at intervals from top to bottom, and the ring pipes 2 in the upper row are aligned with the ring pipes 2 in the lower row. Correspondingly, a row of scaling turbulators 3 distributed at intervals is arranged between the upper row of ring pipes and the adjacent lower row of ring pipes. The way of welding is adopted between the adjacent ring pipes 2, and the scaling spoiler and the ring pipe in contact with the fixed ring are respectively welded to the fixed ring 1, and the gap between the ring pipes is the channel 4 for the flow of the heat exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com