Chaos fin and plate-fin heat exchanger comprising the same

A finned and chaotic technology, applied in the field of heat exchange equipment, can solve the problems of low laminar heat transfer heat transfer efficiency, large turbulent heat transfer and pressure drop, and achieve the effects of simple processing, small flow dead zone, and favorable welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention will be further described:

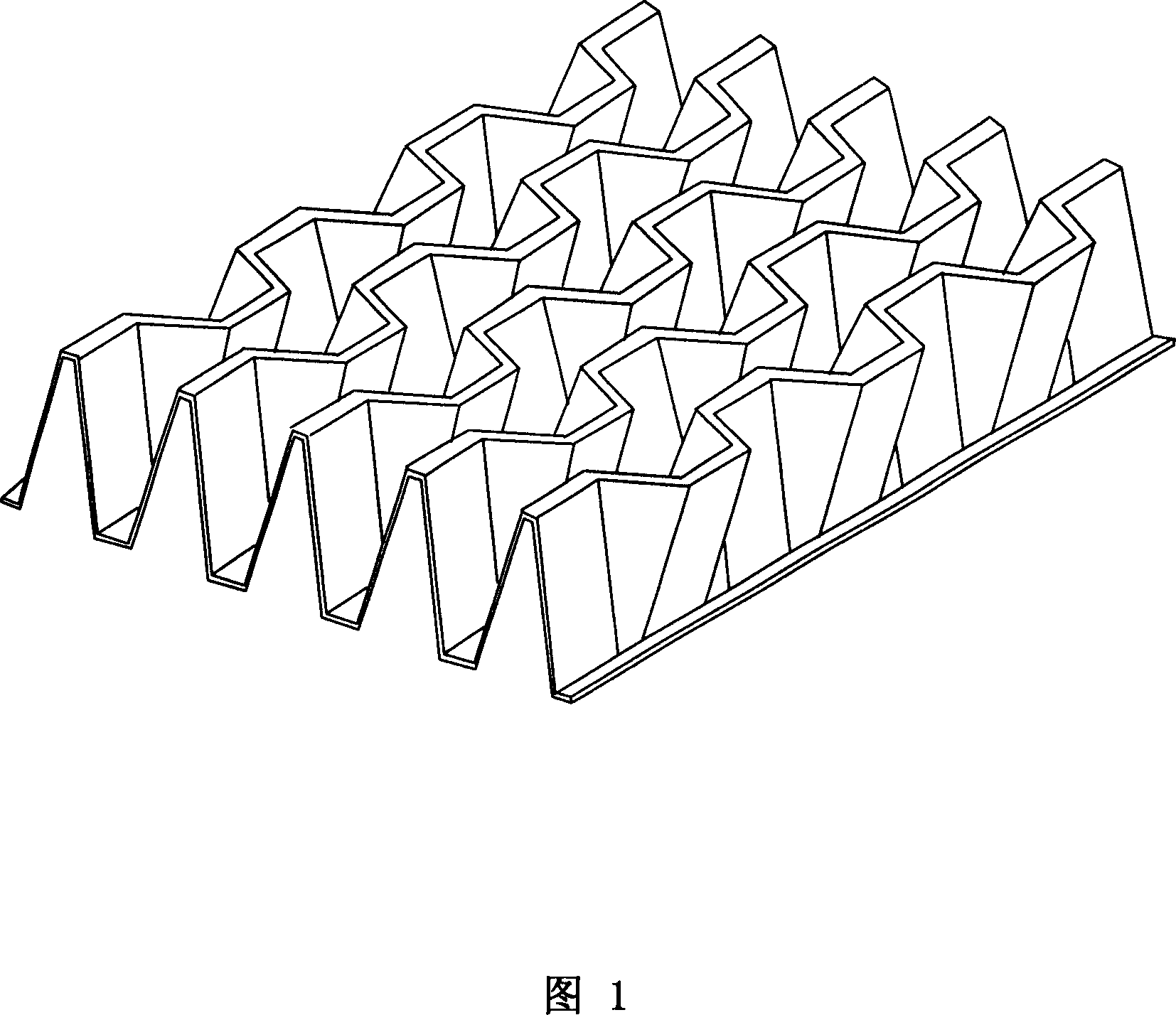

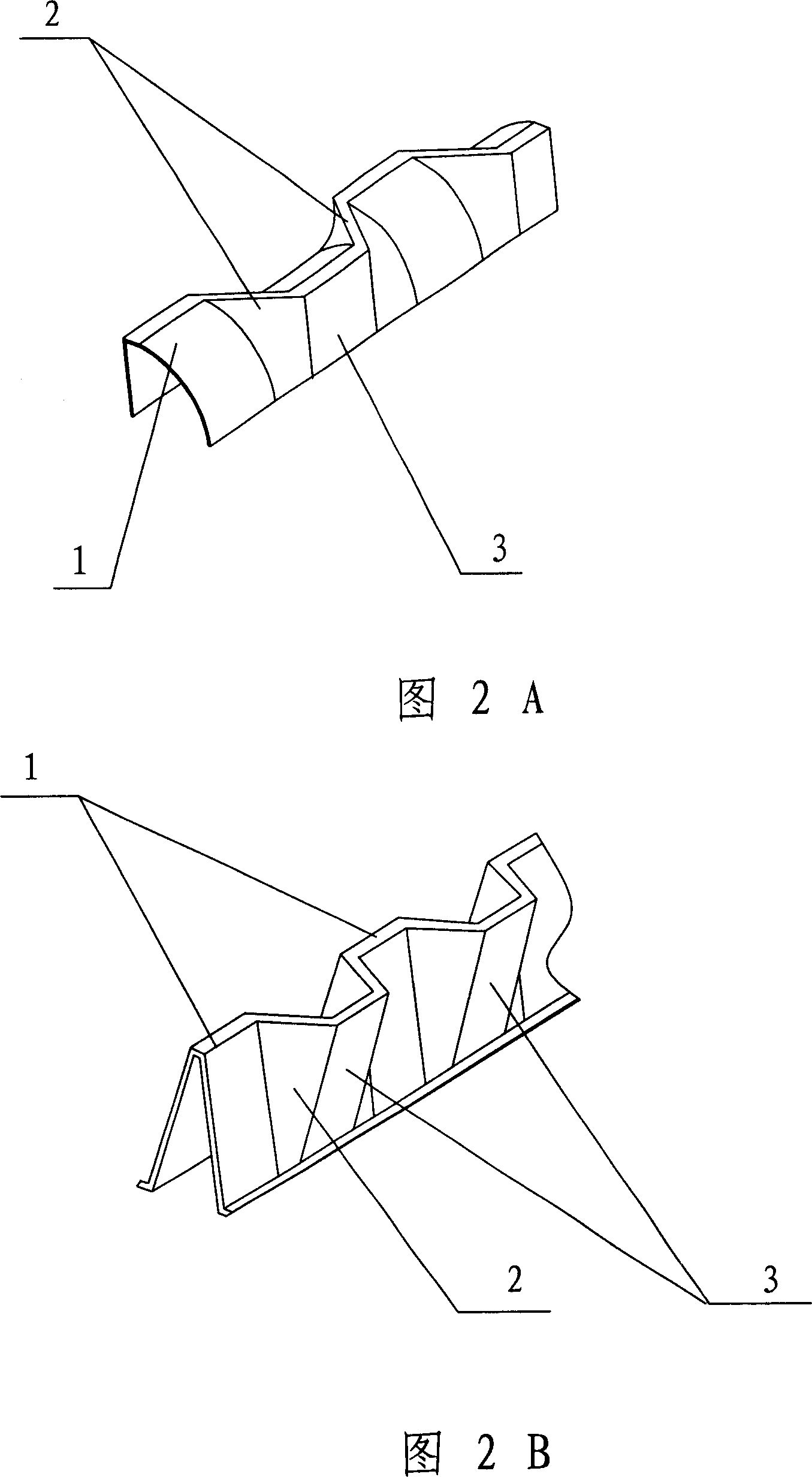

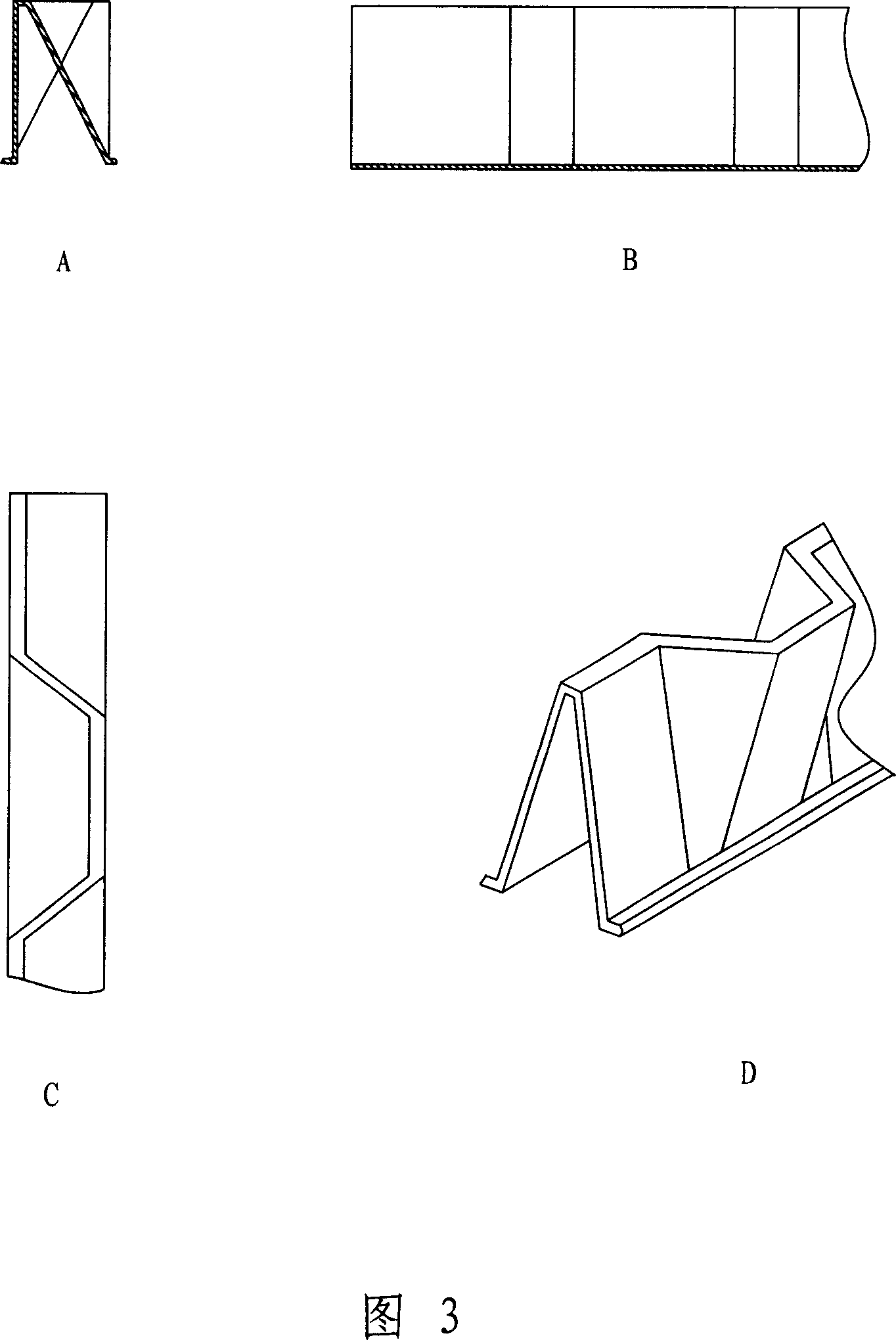

[0021] As shown in Fig. 1, Fig. 2 and Fig. 3, the chaotic fin shown in Fig. 1 is formed by crimping five fin units horizontally. Three units consist of a DC section 1, a twisted DC section 3 and a transition section 2. The front view, left side view, top view and three-dimensional schematic diagram of each unit's DC section 1, twisted DC section 3 and transition section 2 are shown in Figure 3 (A , B, C, D), the adjacent straight section 1 of any unit has the same geometric shape as the twisted straight section 3, and is axisymmetric around the axis perpendicular to the bottom surface of the center of the transition section 2, thus ensuring that the fluid flow in the section The two-dimensional variation on , and has the distortion variation of the third axis. According to the dynamic principle of chaos generation, the fluid in the flow channel is guaranteed to generate c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com