Shell-and-tube heat exchanger with rotary jet-flow baffle plates

A technology of shell-and-tube heat exchangers and baffles, which is applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., which can solve the difficulties in installing spiral baffles, difficulty in ensuring product accuracy, and unfavorable industrial conditions. Standardization and other issues to achieve the effect of simple structure, reduced flow resistance, and reduced flow dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

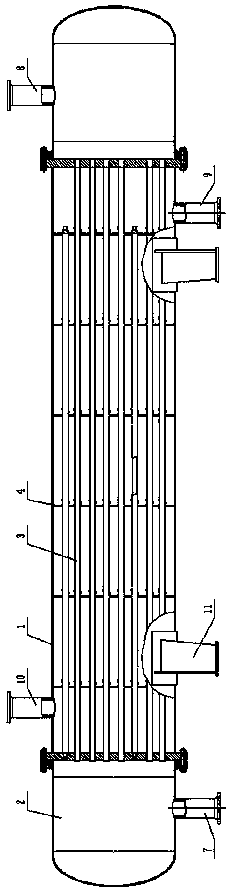

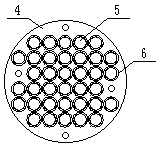

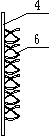

[0016] Such as figure 1 , figure 2 , image 3 As shown, a shell-and-tube heat exchanger with a rotating jet baffle includes: a shell 1 and tube boxes 2 arranged at both ends of the shell 1, wherein a tube side is arranged on the tube box 2 at one end of the shell 1 Fluid inlet, the tube box 2 at the other end is provided with a tube-side fluid outlet, and the shell 1 is provided with a shell-side fluid inlet and a shell-side fluid outlet. The heat exchange tubes 3 are provided with a plurality of baffles 4 arranged in parallel, and each baffle 4 is provided with a plurality of through holes 5, and each heat exchange tube 3 passes through the through holes 5 vertically and runs through each baffle 4. A plurality of swirl fins 6 are arranged in the through hole 5 of each baffle 4 .

[0017] The shape and direction of rotation of the swirl vanes 6 are the same.

[0018] In the orthographic projection of the baffle plate 4 , the swirl fin 6 is in the shape of a ring, the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com