Hall thruster ignition device and method

A Hall thruster and ignition device technology, which is applied in thrust reversers, machines/engines, and the use of plasma, can solve the problems of large payload mass and volume, complex high-voltage power supply technology, etc., to improve ignition reliability, The effect of reducing the mass and volume of the payload and simplifying the complexity of the technical design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

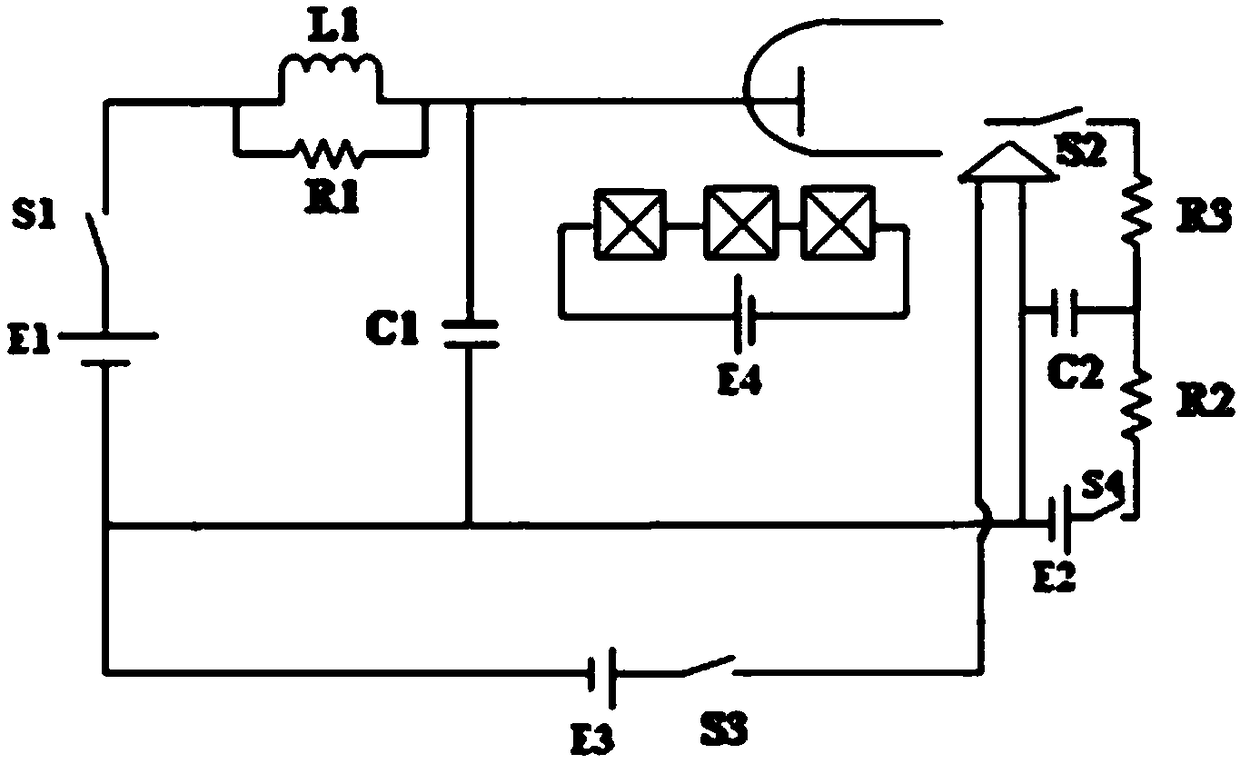

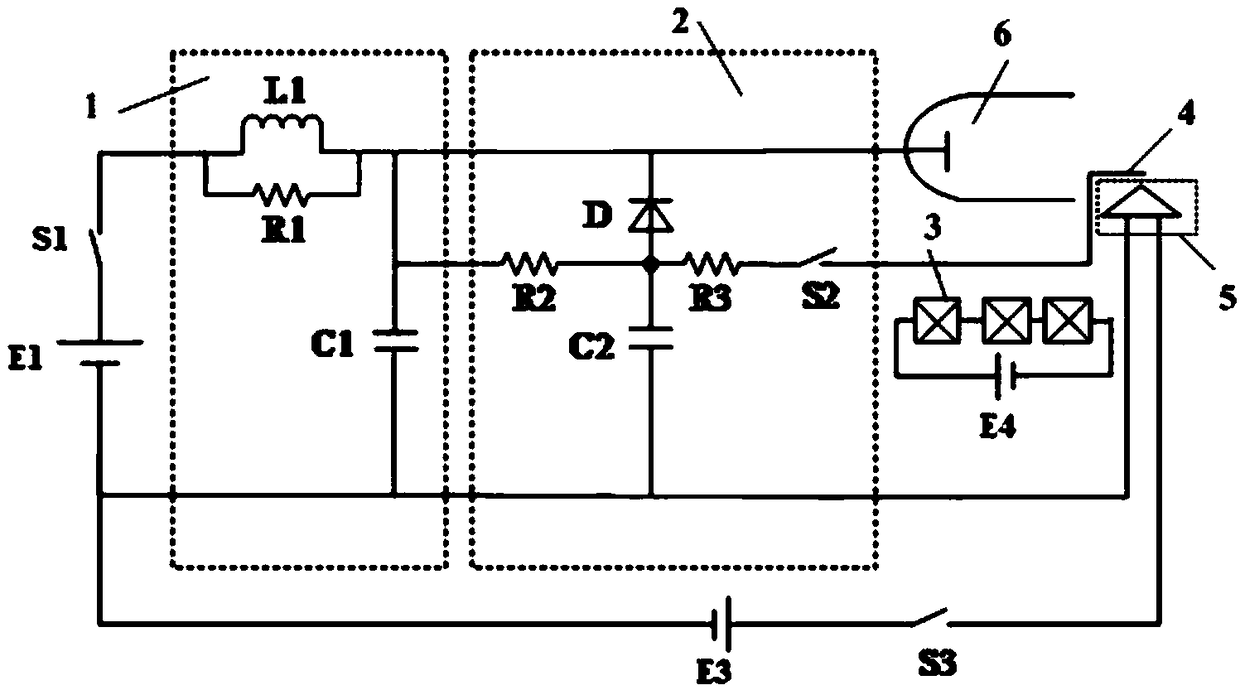

[0035] figure 2 It is a structural schematic diagram of the ignition device of the Hall thruster according to the embodiment of the present invention.

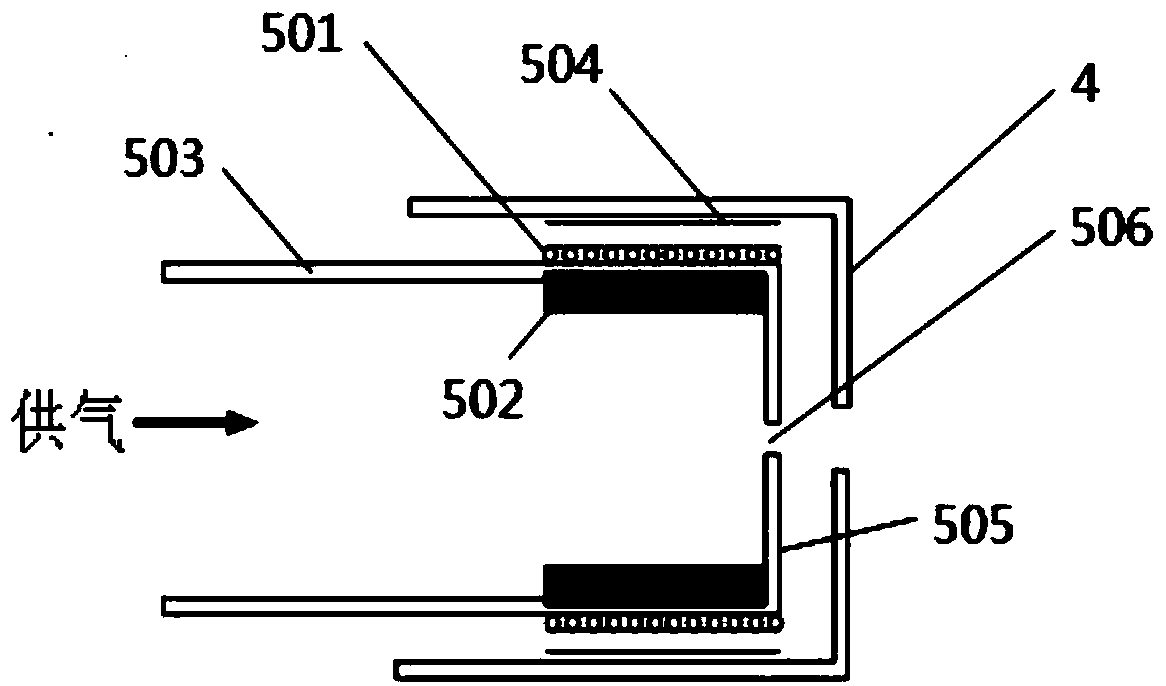

[0036] image 3 It is a schematic diagram of the cathode structure of the Hall thruster in the embodiment of the present invention.

[0037] Such as figure 2 with image 3 As shown, the Hall thruster ignition device provided by the present invention includes: a discharge unit, a filter unit 1, an ignition circuit unit 2, a Hall thruster and a heating unit. The discharge unit includes a discharge power source E1 and a discharge power switch S1, and the discharge power source E1 is connected to the discharge power switch S1. The filter unit 1 includes an inductor L1, a resistor R1 and a capacitor C1. One of the two ends formed by the parallel connection of the inductor L1 and the resistor R1 is connected to the high voltage side of the discharge unit, the other end is connected to one end of the capacitor C1, and the other...

Embodiment 2

[0051] The difference between this embodiment and the first embodiment is that the current-limiting resistor R3=10Ω, the diode D adopts a plurality of diodes connected in series and the reverse cut-off voltage is greater than the ignition voltage, and other components and connections are the same as the first embodiment.

Embodiment 3

[0053] The difference between this embodiment and the first embodiment is that the current-limiting resistor R3=5Ω, the diode D adopts a plurality of diodes connected in series and the reverse cut-off voltage is greater than the ignition voltage, and other components and connections are the same as those of the first embodiment.

[0054] A smaller current-limiting resistor R3 can make more electric energy on the charging capacitor C2 be applied to the cathode contact 4 , thereby extracting electrons faster, improving ignition reliability and shortening ignition time. However, the current-limiting resistor R3 cannot be infinitely small, otherwise the electric energy on the charging capacitor C2 will be applied to the cathode contact electrode 4 instantly, which will have a great impact on the cathode contact electrode 4 and cause the cathode 5 of the Hall thruster to be damaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com