Combustion heater

A technology for burning heaters and fuel oil, which is applied in combustion chambers, combustion methods, and combustion equipment. It can solve the problems of narrow combustion stability range, increased processing costs, and low atomization quality, and achieve novel air intake methods and reliable ignition. High, high combustion efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

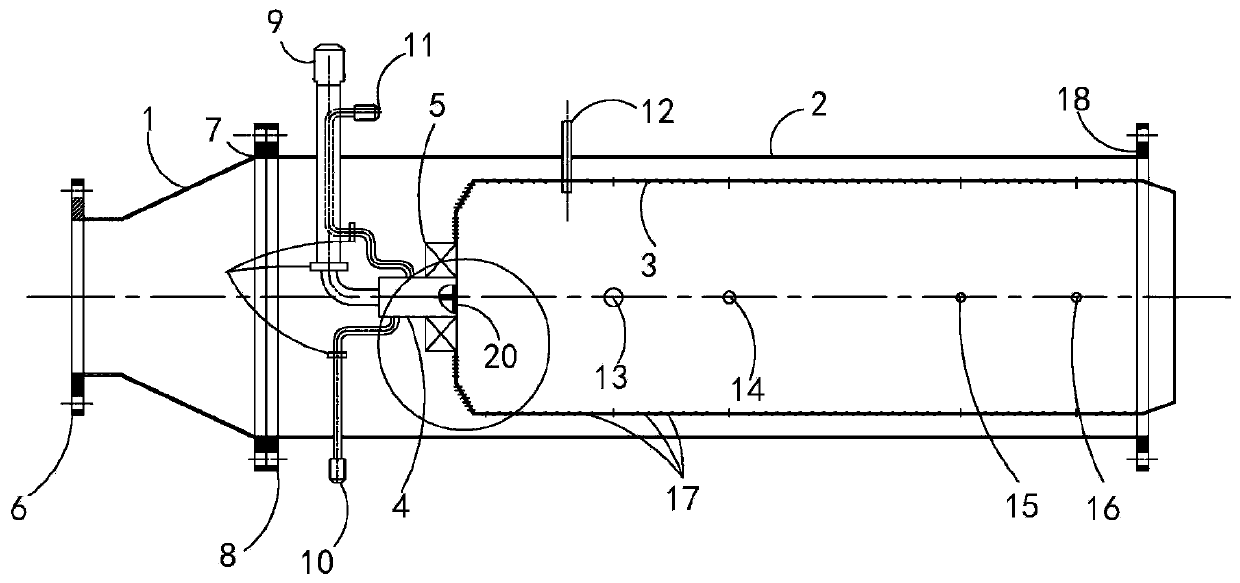

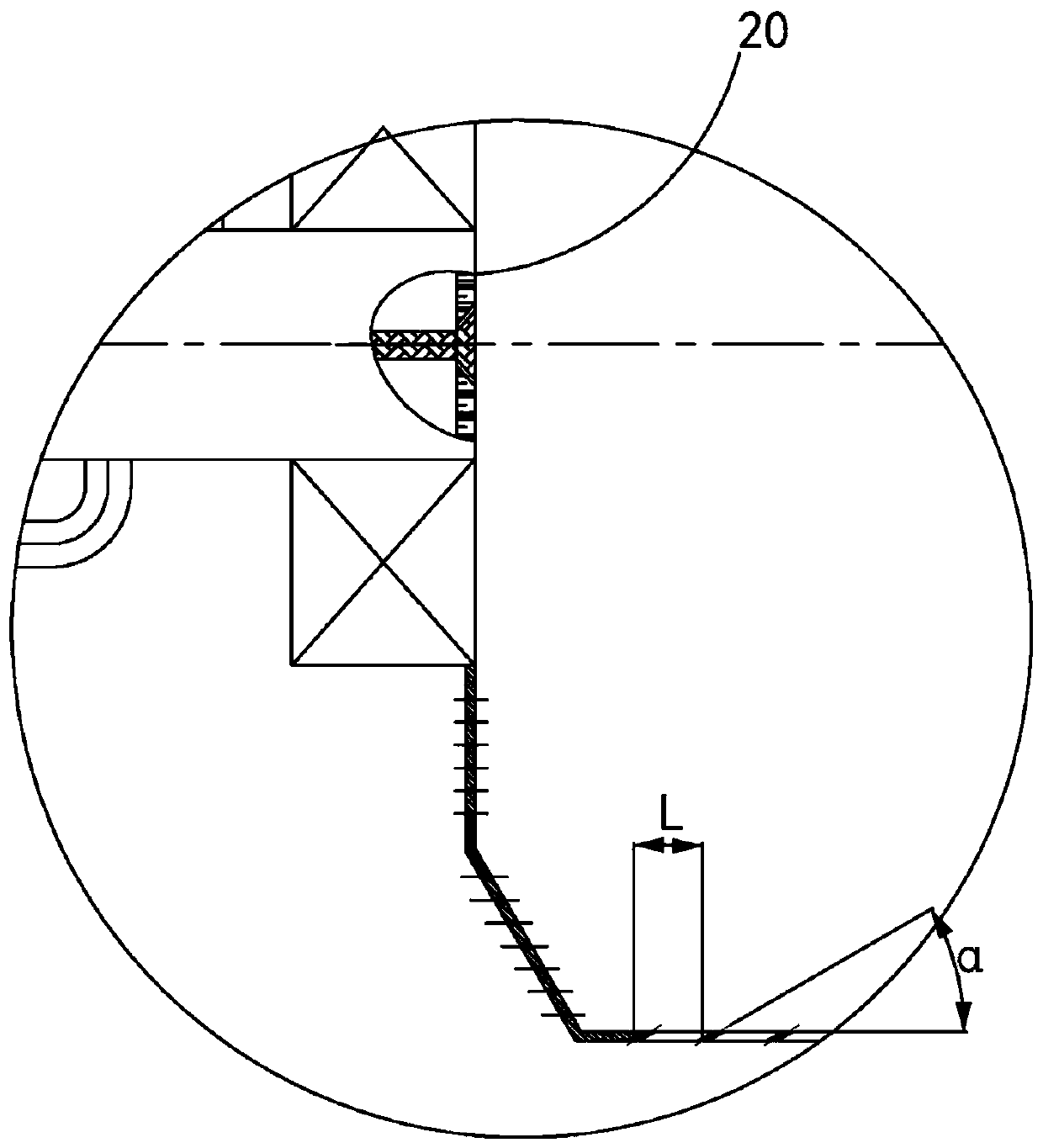

[0052] The technical solution of the present invention will be further described below according to specific embodiments. The protection scope of the present invention is not limited to the following embodiments, and these examples are only for exemplary purposes and do not limit the present invention in any way.

[0053] In the performance test of the main combustion chamber, an indirect heating system is used to heat the inlet airflow of the test piece. The heat exchanger used in the indirect heating system requires a high-temperature airflow to heat the low-temperature inlet air through heat exchange to increase the inlet temperature of the main combustion chamber test piece, thereby meeting the requirements of the main combustion chamber test for the inlet temperature . Because the indirect heating system puts forward higher requirements on the reliability of the combustion heater and the unevenness of the outlet temperature distribution, it is difficult for the existing com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com