Infrared ray gas burner

a gas burner and infrared ray technology, applied in the field of gas burners, can solve the problems of incomplete combustion, misfire or deflagration, and difficulty in directly igniting the gas-air mixture escaping from the fire hole by pulse electrical sparkle or piezoelectric ceramic ignition, etc., and achieves the effect of relatively high gas concentration, rapid igniting, and suitable igniting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

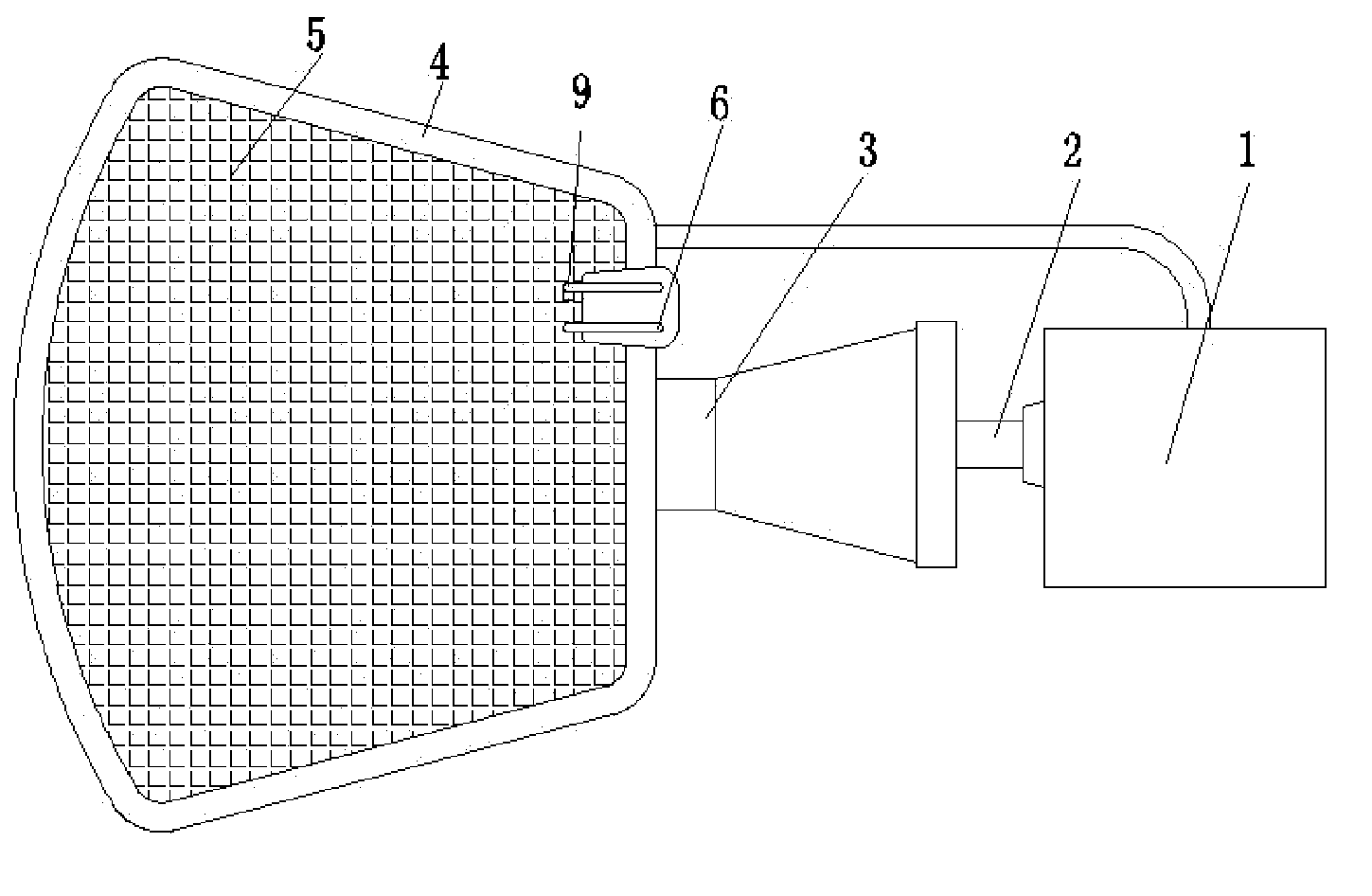

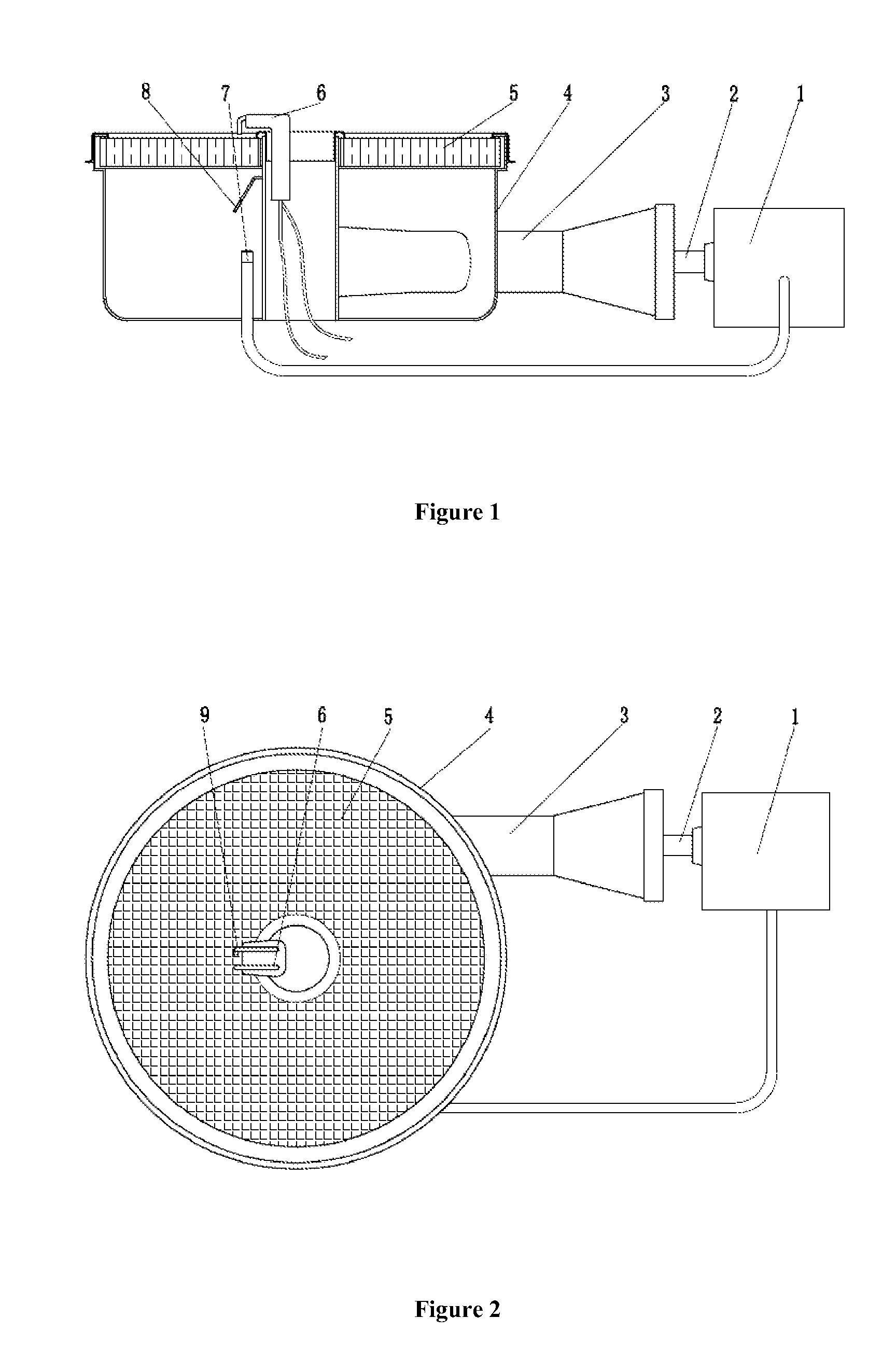

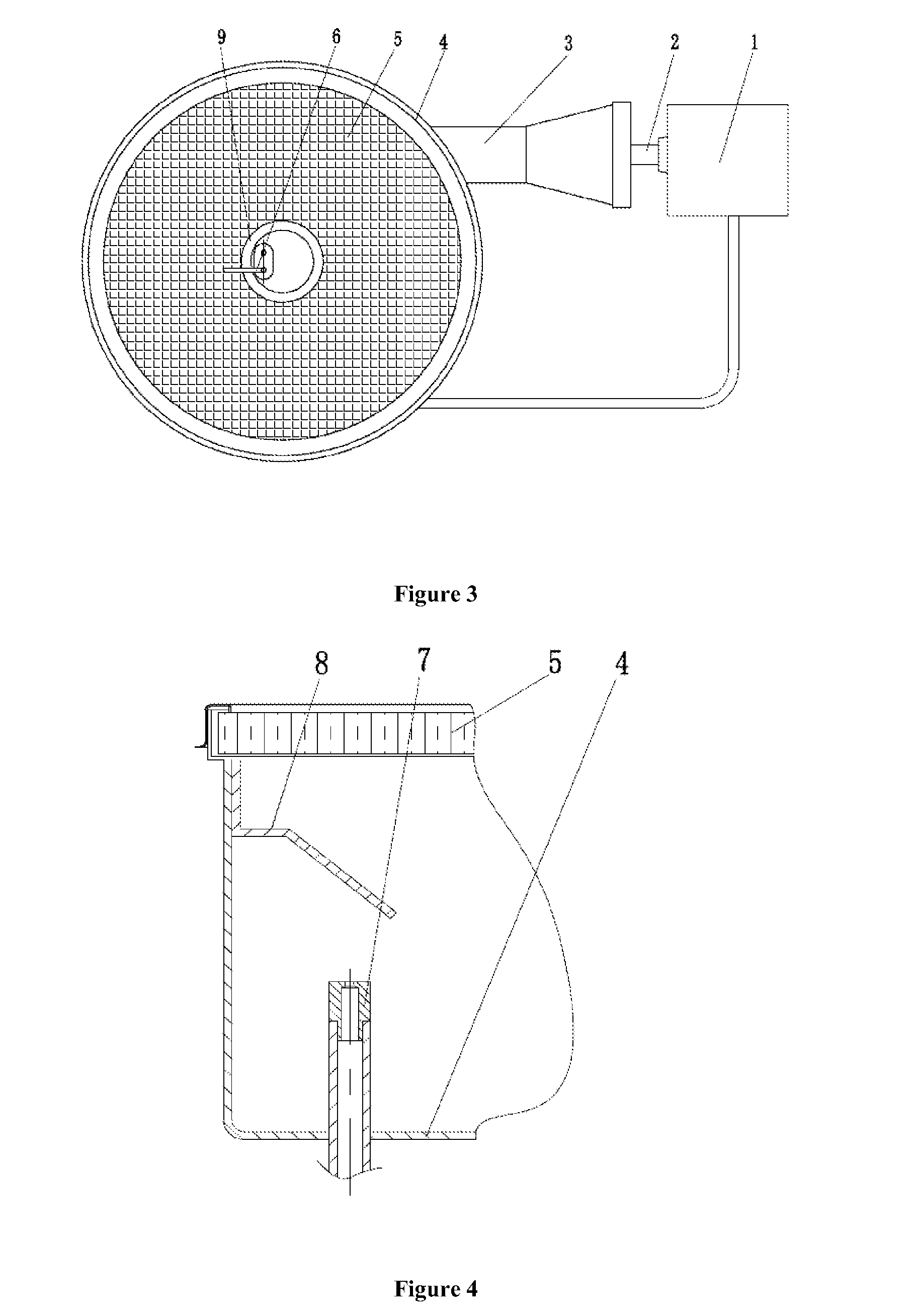

example 1 (figs.1 , 2 and 4)

Example 1 (FIGS. 1, 2 and 4)

[0031]An infrared ray gas burner for domestic use, comprises an ignition valve 1, a nozzle 2, an ejector 3, a furnace chamber 4, a porous combustion radiant panel 5 and an ignition needle 6, an ignition nozzle 7 passes through the furnace chamber 4 and is settled in the chamber body of the furnace chamber 4 and below the porous combustion radiant panel 5, a sundries baffle 8 is provided in the furnace chamber 4 below the porous combustion radiant panel 5 and above the ignition nozzle 7, the ignition needle 6 is set above the porous combustion radiant panel 5 which is set above the ignition nozzle 7, the needle apex of the ignition needle 6 is placed 3 mm above the porous combustion radiant panel 5, and the burner is provided with an independent ignition negative pole 9, which, together with the ignition needle 6, forms a ignition circuit; the burner is a simple ring burner; the porous combustion radiant panel 5 is a porous ceramic radiant panel. Therefore...

example 2 (figs.1 , 3 and 4)

Example 2 (FIGS. 1, 3 and 4)

[0032]It is substantially the same as Example 1, differing only in that the ignition negative pole of the ignition needle 6 is the housing of the furnace chamber 4.

example 3 (figs.1 , 3 and 4)

Example 3 (FIGS. 1, 3 and 4)

[0033]It is substantially the same as Example 1, differing only in that the ignition negative pole of the ignition needle 6 is the housing of the furnace chamber 4, the ignition needle 6 is used both as a flame ionization probe of an accidental flameout protection device and as an ignition needle for ignition flame; the circuit of the pulse controller is designed such that the ignition needle 6 emits ignition sparks at the beginning of the ignition, and after the burner is ignited, the ignition needle 6 immediately becomes a probe for detecting the combustion flame signal of the burner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com