High-pressure intensity and mass-flow liquid oxygen kerosene engine plasma ignition device

A plasma and ignition device technology, which is applied in the directions of combustion ignition, incandescent ignition, combustion method, etc., can solve the problems of inability to integrate and low degree of automation of plasma igniters, achieve simple and reliable feedback adjustment circuit, and improve ignition reliability. and service life, the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

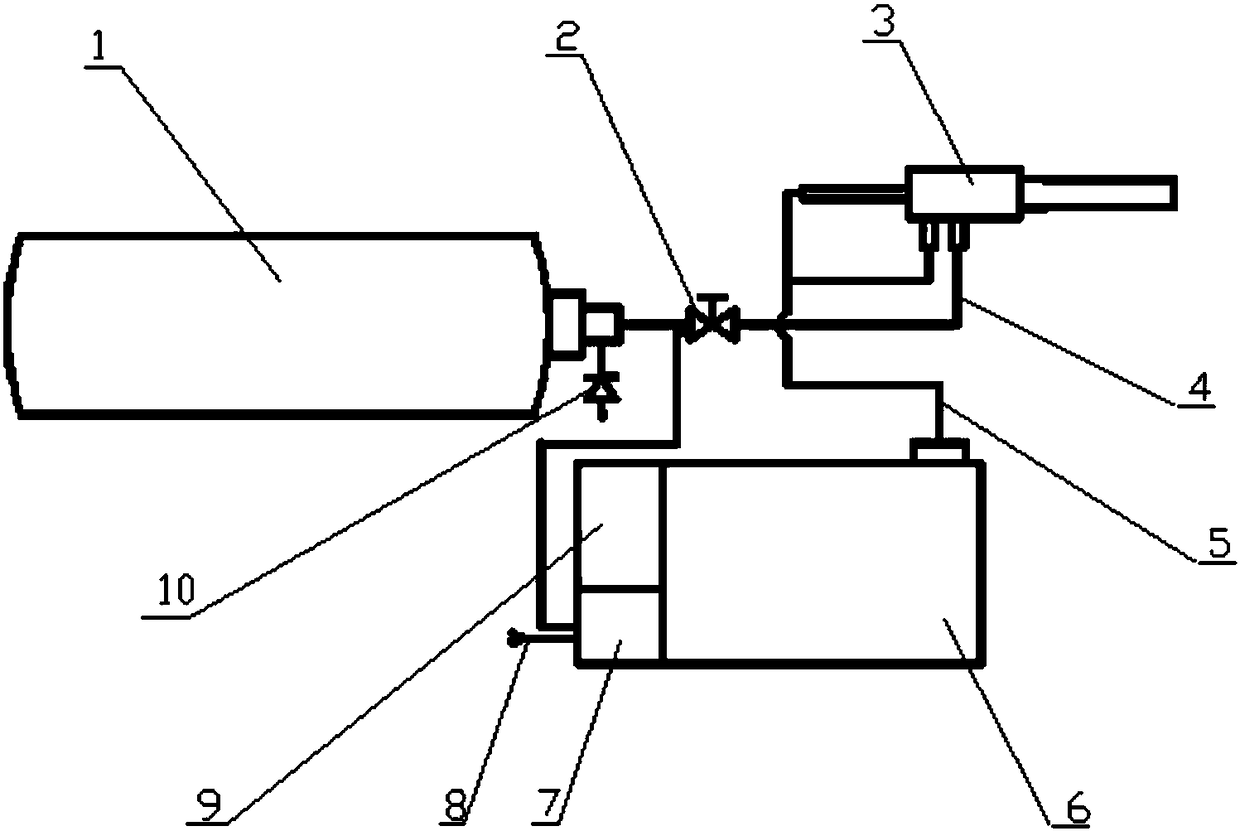

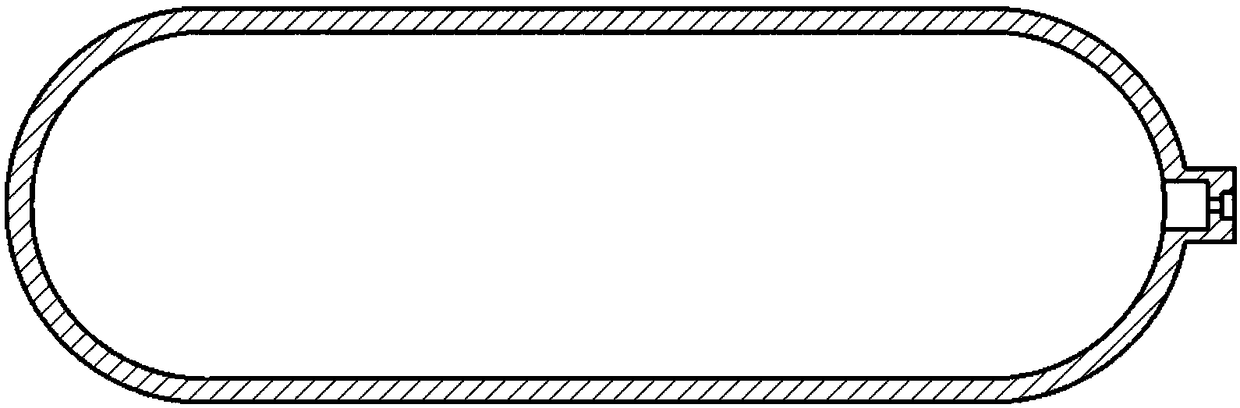

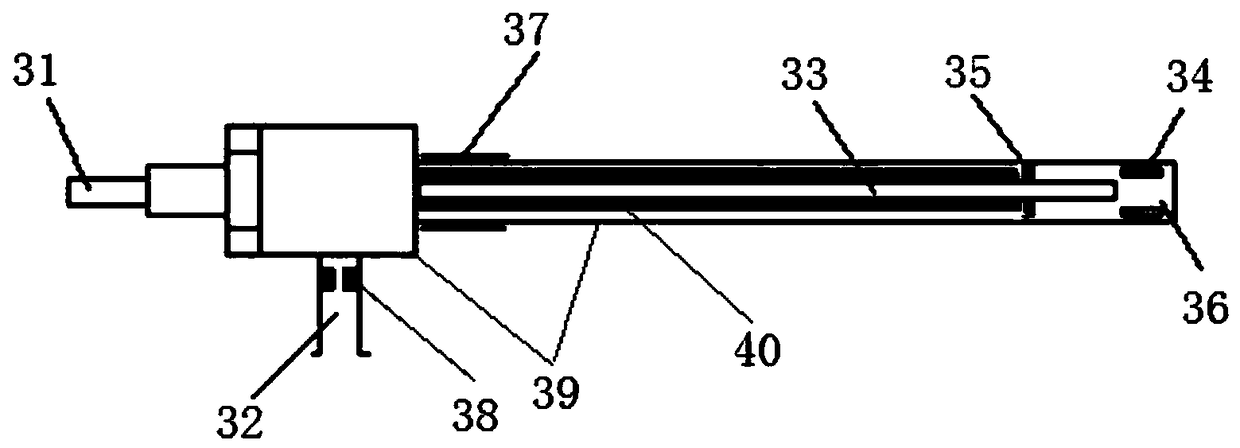

[0037] combine figure 1 It can be seen that the present invention includes a gas bottle 1, a plasma torch 3, a drive module 6, a measurement and control module 7, and a battery 9; the gas bottle 1 has a volume of 3L, an operating pressure of 25MPa, and is equipped with a one-way filling valve 10. When the air pressure outside the filling valve is higher than the air pressure in the gas cylinder 1, the gas cylinder 1 can be inflated. The gas outlet of the gas cylinder 1 communicates with the gas inlet 32 of the plasma torch 3 through the high-pressure solenoid valve and the gas supply pipeline 4. No power supply is required when the power is on and off, and the mass is 0.2kg; the gas supply pipeline 4 is a conventional high-pressure metal pipe with a diameter of 3 mm; the plasma torch 3 can work under a room pressure environment of 20 MPa, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com