Manufacturing method of potassium picrate-red lead silicon series electric ignition charge

A kind of technology of potassium picrate and its manufacturing method, applied in explosives, compositions containing nitrated metal-organic compounds, offensive equipment, etc., can solve the problems of high friction sensitivity and mechanical sensitivity, unfavorable basic detonator safety, and large environmental pollution, etc. Achieve high ignition reliability, improve ignition reliability, and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

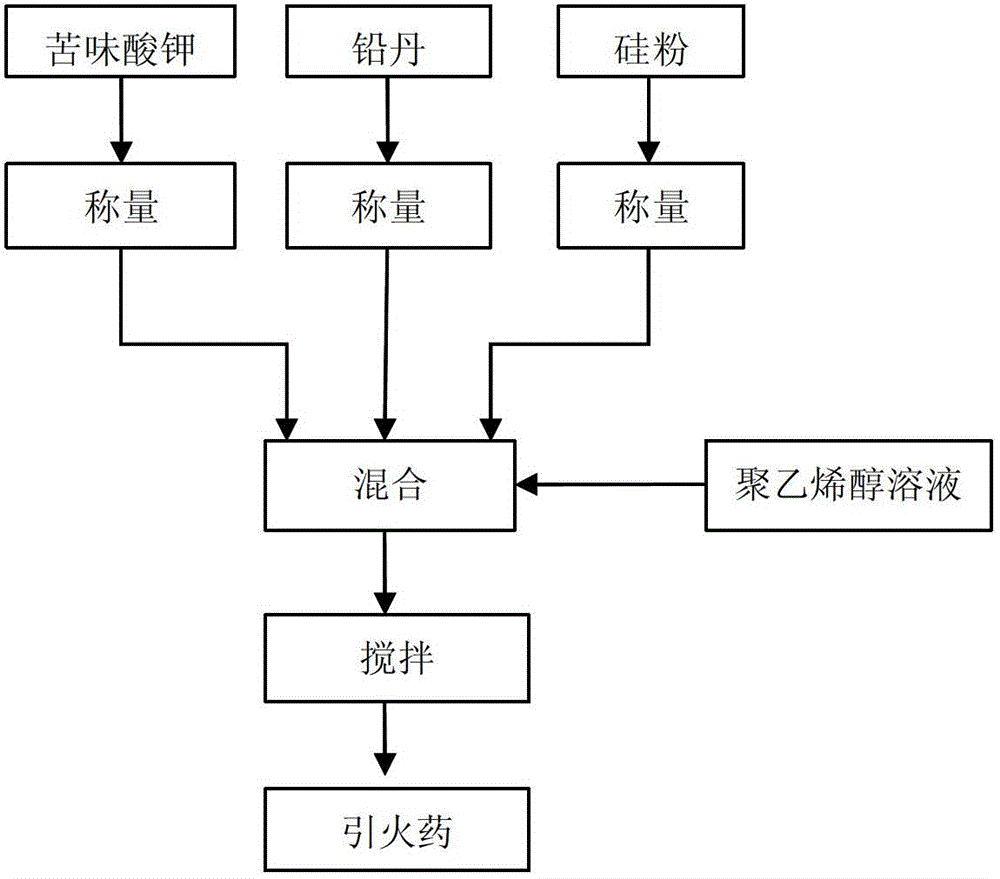

[0016] Attached below figure 1 The present invention will be further described in detail with specific embodiments. as the picture shows:

[0017] The production example is: Weighing and mixing: Weigh 50 grams of potassium picrate (water content less than 0.1%), 50 grams of lead, silicon and iron powder (ratio: 9:1), measure 15ml of polyvinyl alcohol aqueous solution, and pour them in turn Put it into a 300ml glass beaker, stir it evenly with a bakelite stick, then sieve it, and continue stirring for 40 minutes. After mixing evenly, let it stand for use.

[0018] Wipe the primer: spread the above-mentioned viscous agent evenly around the bridge wire of the electric ignition head. Pores, cracks, defects, and exposed bridge wires are not allowed to appear on the good ignition powder. The weight of the ignition powder Between 8 and 12mg. Drying at 35-45°C until the moisture content is less than 0.1%, the manufacture of the ignition powder of the present invention is completed....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com