A self-excited multi-point jet plasma igniter

A jet plasma and plasma technology, which is used in machines/engines, jet propulsion devices, gas turbine devices, etc., can solve the problem that the reliable ignition range cannot meet the actual needs, etc., and achieve the effect of strong ignition ability and improved ignition ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

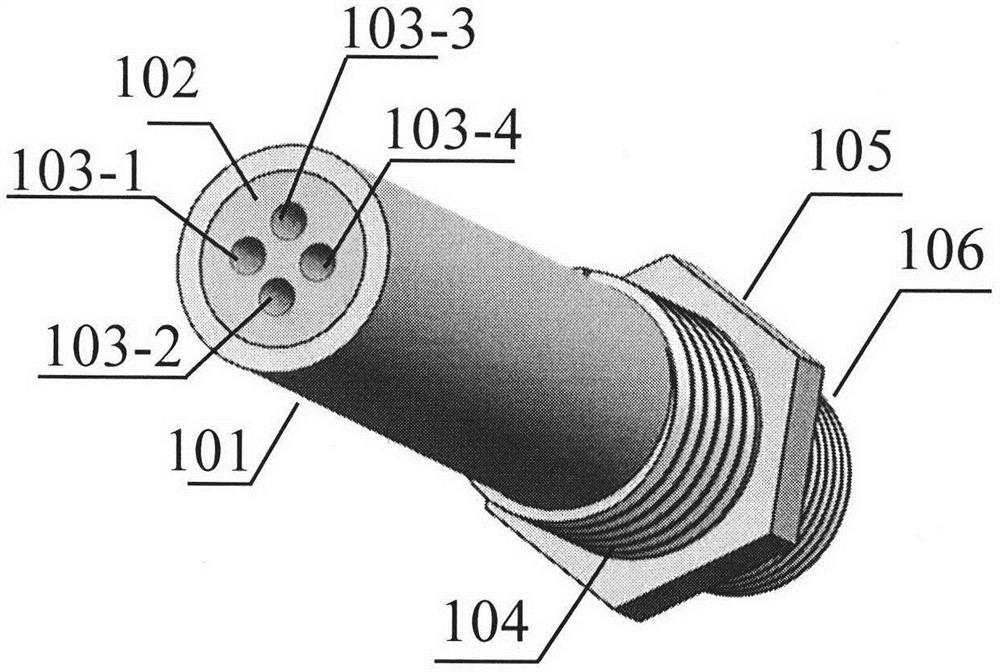

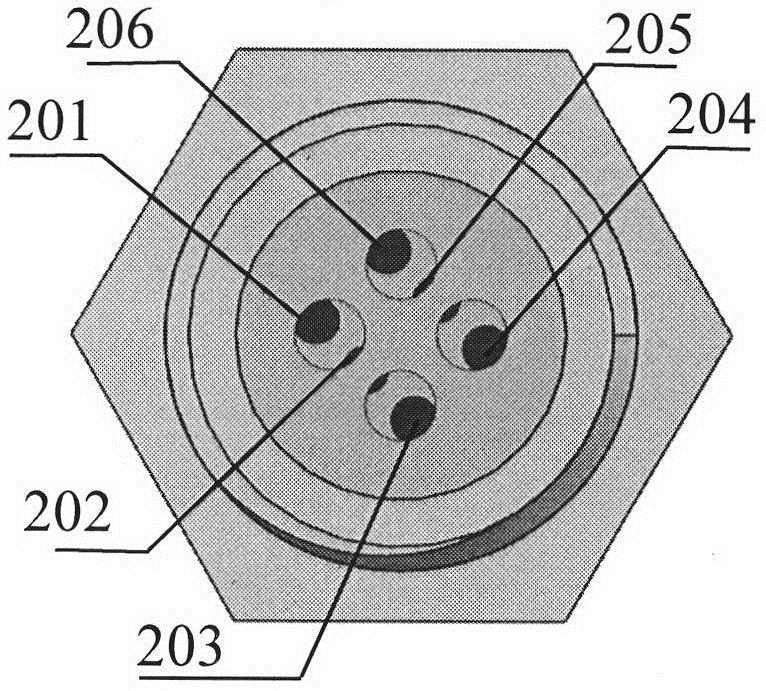

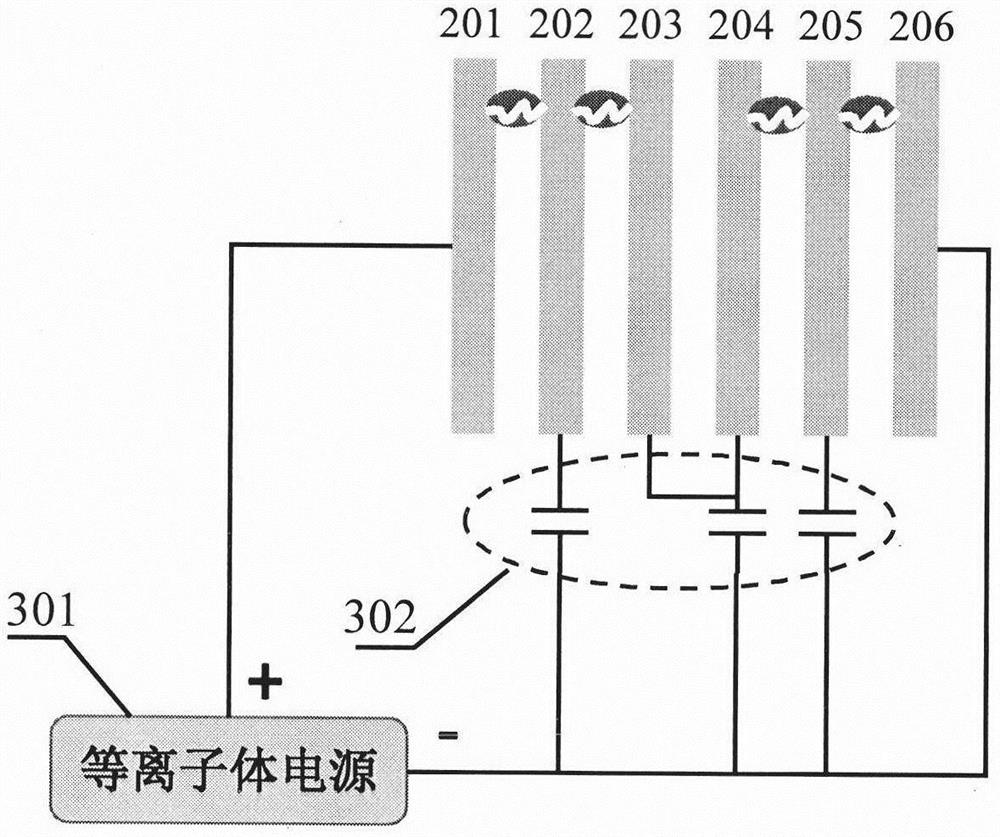

[0041] In one embodiment of the present invention, the self-excited multi-point jet plasma igniter consists of a housing 101, an insulator 102, a jet cavity (103-1 to 103-4), a mounting thread 104, a positioning hexagonal boss 105, The ignition cable is connected to thread 106 and discharge electrodes (201-206). The shell 101 is processed by high temperature resistant nickel-based superalloy, and the whole is a hollow cylindrical structure with a diameter of 18mm. The inside is processed with a through hole to install the insulator 102. The diameter of the hole is 14mm. The outside is processed with a mounting thread 104 and a positioning hexagonal boss 105 and ignition cable connection thread 106. The insulator 102 is made of high-temperature-resistant ceramics, embedded in the igniter housing 101 , and has a cylindrical shape with the same diameter as the through hole of the housing 101 . A plurality of circular cavities are processed at intervals on the end face of the ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com