High-energy-point gunpowder and preparation method

A kind of ignition powder and high-energy technology, applied in the field of high-energy ignition powder and preparation, can solve the problems of expensive raw material boron and limited use range, and achieve the effects of high ignition reliability, reduced sensitivity and high energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

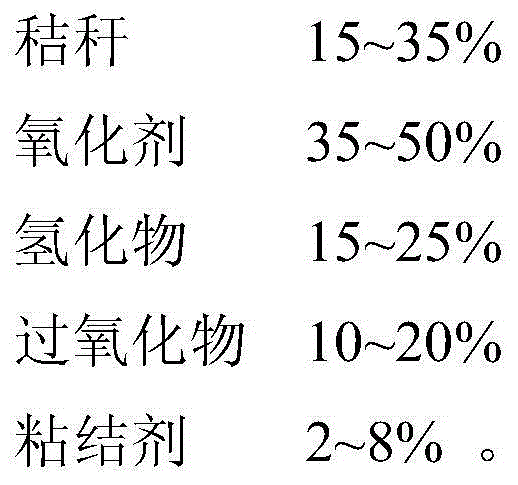

[0025] A high-energy ignition powder, the quality of each component in the formula is: 20g corn stalks, 43g potassium nitrate, 20g cerium hydride, 15g calcium peroxide, 2g ethyl acetate;

[0026] A kind of preparation method of high-energy ignition powder, concrete steps are as follows:

[0027] 1) Weigh 20g corn stalks, 43g potassium nitrate, 20g cerium hydride, 15g calcium peroxide, 2g ethyl acetate;

[0028] 2) Divide the binder into four parts, the first part is 0.04g, the second part is 0.086g, the third part is 0.03g, and the fourth part is 1.844g;

[0029] 3) The first, second, and third binders were added dropwise to the weighed hydride, oxide, and peroxide, and kneaded for 20 minutes after the dropwise addition; dried for 5 hours at a temperature of 30°C. Grind and pass through a 100-mesh sieve, wherein the dropping rate is 20 drops per minute;

[0030] 4) Mix the coated substance and straw obtained in 3) evenly, add 1.866g dropwise for bonding, knead for 30min, and...

Embodiment 2

[0033] A high-energy ignition powder, the quality of each component in its formula is: 35g sorghum straw, 32g potassium perchlorate, 15g lanthanum hydride, 10g potassium peroxide, 8g polyglycidyl ether nitrate;

[0034] A kind of preparation method of high-energy ignition powder, concrete steps are as follows:

[0035] 1) Weigh 35g of sorghum straw, 32g of potassium perchlorate, 15g of lanthanum hydride, 10g of potassium peroxide, and 8g of polyglycidyl ether nitrate.

[0036] 2) Take out 0.015g, 0.032g, and 0.02g from the binder, add them dropwise to lanthanum hydride, potassium perchlorate, and potassium peroxide, and knead for 15 minutes; dry for 5 hours at a temperature of 30°C, grind, Through a 100-mesh sieve, the dropping rate is 20 drops per minute;

[0037] 3) Mix the coated substance and straw obtained in 2) evenly, add 7.933g dropwise for bonding, knead for 30min, and pass through a 20-mesh sieve to form granules;

[0038] 4) Dry the granular material at 40°C and a...

Embodiment 3

[0040] A high-energy ignition powder, the quality of each component in its formula is: 15g cotton stalks, 50g potassium perchlorate, 17g aluminum hydride, 15g potassium peroxide, 3g nitrated polybutadiene;

[0041] A kind of preparation method of high-energy ignition powder, concrete steps are as follows:

[0042] 1) Weigh 15g of cotton stalks, 50g of potassium perchlorate, 17g of aluminum hydride, 15g of potassium peroxide, and 3g of nitrated polybutadiene.

[0043] 2) Take out 0.051g, 0.05g and 0.03g respectively from the nitrated polybutadiene, add them dropwise to aluminum hydride, potassium perchlorate and potassium peroxide respectively, knead for 25min; dry at 30°C for 5h, Grind and pass through a 100-mesh sieve, wherein the dropping rate is 20 drops per minute;

[0044] 3) Mix the coated substance and straw obtained in 2) evenly, add 2.869 g of nitrated polybutadiene dropwise, knead for 30 minutes, and pass through a 20-mesh sieve to form granules;

[0045] 4) Dry th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com