A kind of permeable foam concrete and preparation method thereof

A foam concrete and foam technology, applied in the field of permeable foam concrete and its preparation, can solve problems such as difficult to achieve sponge city, achieve good water permeability, good water permeability and use performance, and solve the effect of poor water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

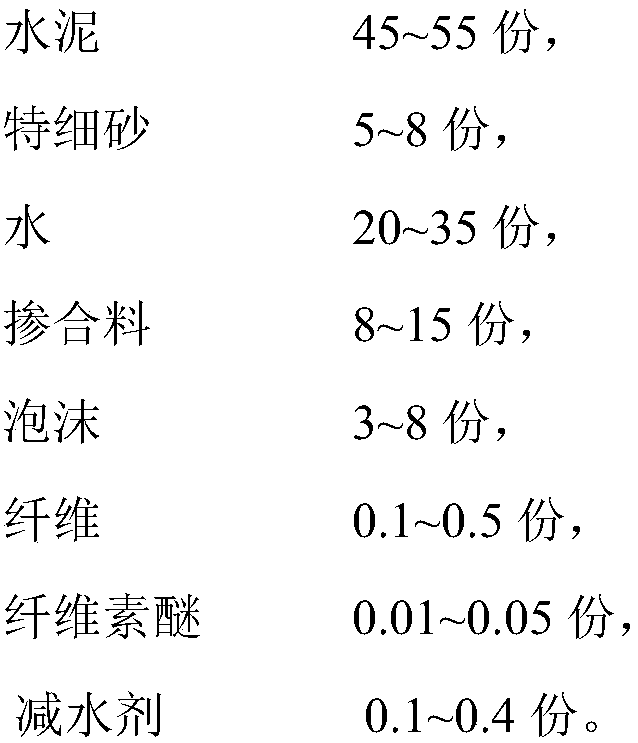

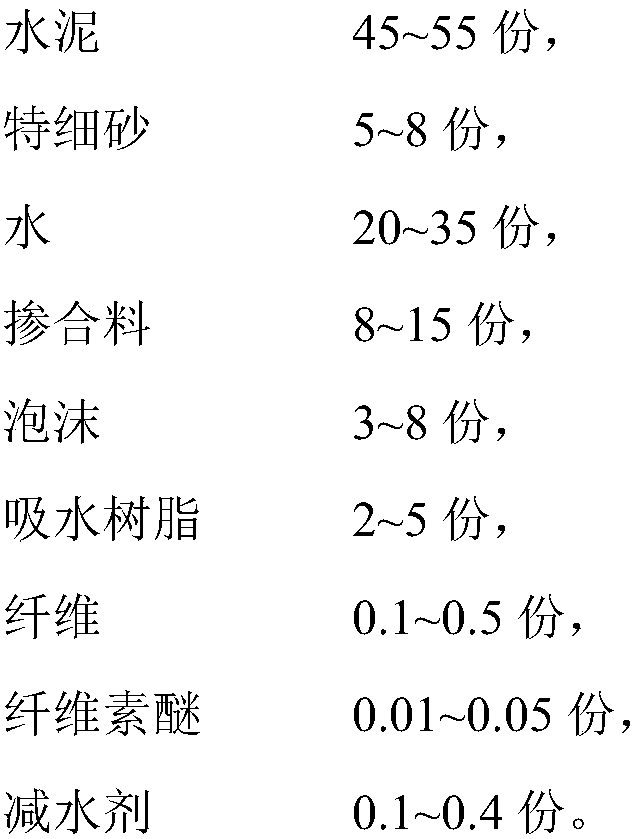

Method used

Image

Examples

Embodiment 1~5

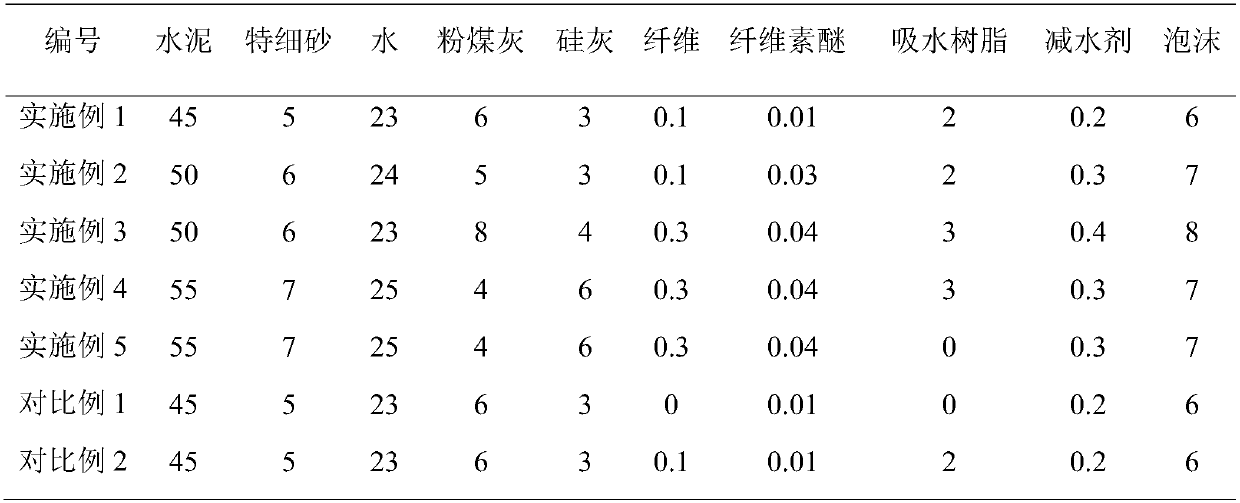

[0027] A kind of water-permeable foam concrete, the ratio of each raw material is shown in Table 1 respectively, and its preparation method comprises the following steps: according to the ratio, take the required raw materials, dilute the foaming agent by 60 times, prepare the foaming liquid, and then inject Foaming machine; add cement, ultra-fine sand, admixture, fiber, water-absorbing resin, and cellulose ether into the mixer for dry mixing for 15 seconds, then add water and water reducing agent and stir for 15 seconds to obtain the mixture; immediately prepare the foam (the resulting foam The density is 40kg / m 3 ), add foam to the mixture according to the ratio described in Table 1, continue to stir for 90s, and mix evenly to obtain the permeable foam concrete.

[0028] Table 1 Proportioning (parts by weight) of each raw material in the permeable foam concrete described in Examples 1 to 5

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com