A kind of high-rate lithium-ion battery, aging and formation method

A lithium ion battery, a technology of chemical formation method, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of electrolyte decomposition, poor infiltration effect of pole pieces, limited effect, etc., and achieve strong mechanical stability, Excellent performance and the effect of promoting uniform infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of the high-rate battery is as follows:

[0046] Positive plate preparation: According to lithium cobaltate 90%, superconducting carbon black 2%, carbon nanotube 3.5%, polyvinylidene fluoride 4.5%, weigh each raw material, dissolve polyvinylidene fluoride in solvent (NMP), low speed 20rpm / min, high speed 1200rpm / min, stirring and dispersing for 90min to prepare glue; then add half of the superconducting carbon black to the glue, high speed 40rpm / min, high speed dispersing 2500rpm / min, stirring and dispersing time 60min, get a conductive glue; then add the other half of the superconducting carbon black into the primary conductive glue, stir at a high speed of 40rpm / min, and disperse at a high speed of 2500rpm / min for 60min to obtain a secondary conductive glue; add CNTS to the secondary In the conductive glue, the stirring speed is 40rpm / min, the dispersion speed is 3000rpm / min, the stirring and dispersing time is 60min, and the conductive glue is...

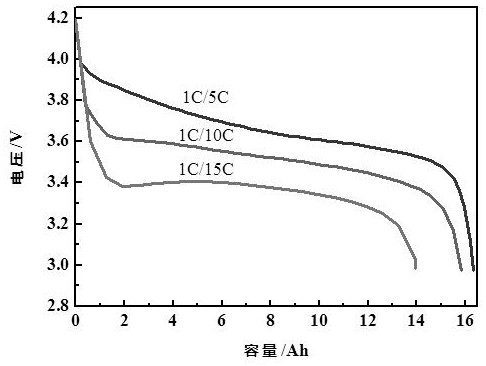

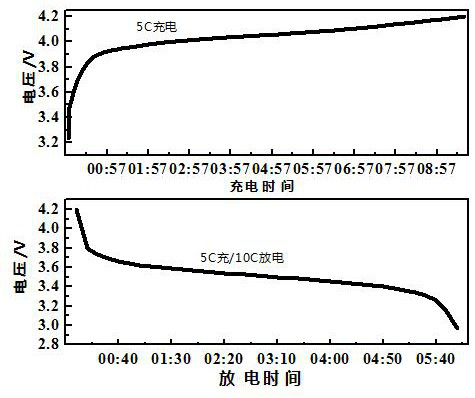

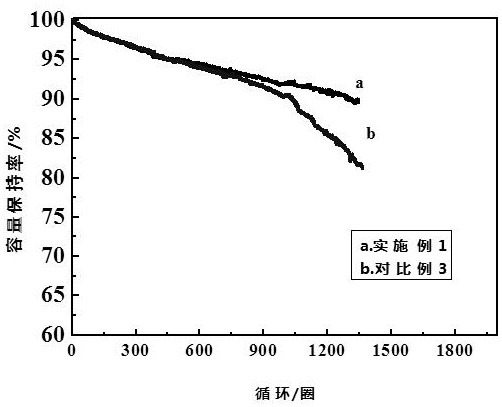

Embodiment 1

[0051] The A1, B1, and C1 batteries prepared above are subjected to the following formation operations:

[0052] High temperature aging steps:

[0053] Step 1: Preheat the cell at 45°C for 20 minutes, and then pre-press and shape it. The shaping pressure is 50Kg and the time is 20 minutes;

[0054] Step 2: Release the pressure to 0Kg, age at a high temperature for 48 hours, and the aging temperature is 45°C; after the aging, keep the temperature and increase the pressure to 800Kg until the formation is completed.

[0055] The first step of formation:

[0056] Step 1: Charge to 10% of the design capacity of the battery at a constant current of 0.1C, set aside for 4 hours at a high temperature of 45°C and a pressure of 800Kg;

[0057] Step 2: Discharge at a constant current of 0.1C to 4% of the battery design capacity, and let it stand for 10 minutes;

[0058] Step 3: Charge to 10% of the design capacity of the battery with a constant current of 0.1C, and let it stand for 10 ...

Embodiment 2

[0086] A3 batteries were taken for different aging-formation operations, and the batteries were pumped and sealed to prepare a 16Ah pouch battery. When the battery is formed, only the charge and discharge rate of the first stage of formation is changed from 0.1C to 0.2C; the rate of charge and discharge of the second stage of formation is changed from 0.2C to 0.4C; C, all the other parameters and operations are the same as in Example 1. The specific steps are as follows:

[0087] High temperature aging steps:

[0088] Step 1: Preheat the cell at 45°C for 20 minutes, and then pre-press and shape it. The shaping pressure is 50Kg and the time is 20 minutes;

[0089] Step 2: Release the pressure to 0Kg, age at a high temperature for 48 hours, and the aging temperature is 45°C; after the aging, keep the temperature and increase the pressure to 800Kg until the formation is completed.

[0090] The first step of formation:

[0091] Step 1: Charge to 10% of the design capacity of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com