A kind of medium temperature carbon dioxide adsorbent and its preparation and use method

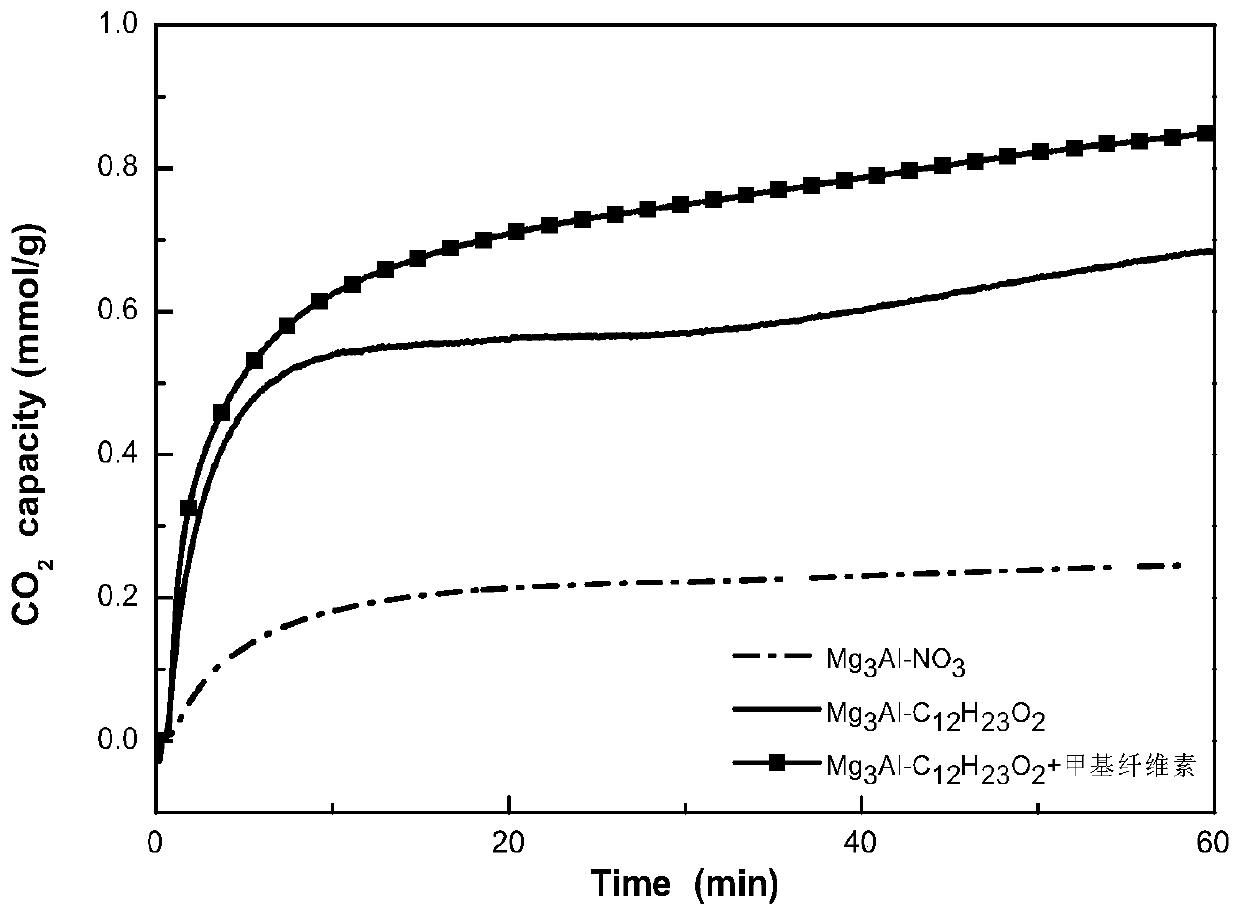

A carbon dioxide and adsorbent technology, which is applied in the field of medium-temperature carbon dioxide adsorbents, can solve the problems of low adsorption capacity of medium-temperature carbon dioxide adsorbents, and achieve the effects of excellent adsorption performance, improved processing efficiency, and increased average pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1). Accurately weigh 15.385g Mg(NO 3 ) 2 ·6H 2 O and 7.51gAl(NO 3 ) 3 9H 2 O dissolved in 100ml to remove CO 2 prepared in deionized water containing [Mg 2+ ]=0.6mol / L, [Al 3+ ]=0.2mol / L mixed salt solution; Weigh 6.4g solid NaOH and dissolve in 100ml to remove CO 2 Prepare a 1.6mol / L alkaline solution in deionized water.

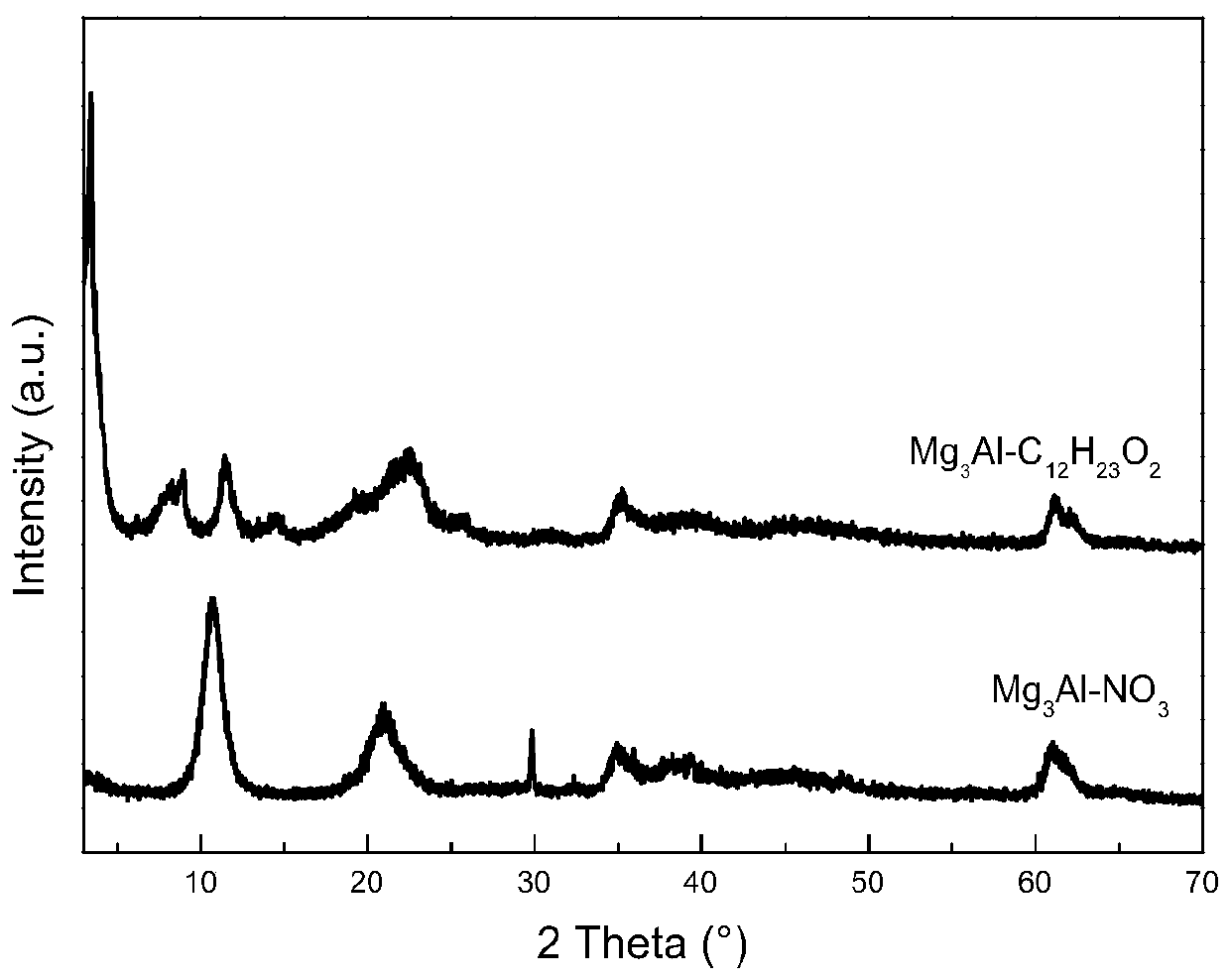

[0025] (2). Use the nucleation crystallization isolation method to prepare the hydrotalcite precursor. Add the mixed salt solution and the mixed alkali solution in step (1) dropwise to the colloid mill at the same speed. The stirring speed of the colloid mill is 3000rmp, and the obtained The slurry was quickly transferred to a 500ml three-necked bottle, and the slurry was crystallized at 80°C for 8 hours under nitrogen protection, and then deCO2 2Washed with deionized water to neutrality, the slurry-like intercalated hydrotalcite precursor Mg 3 Al-NO 3 -LDH.

[0026] (3). Disperse intercalated hydrotalcite precursor in CO removal 2 0.01...

Embodiment 2

[0031] (1). Accurately weigh 15.385g Mg(NO 3 ) 2 ·6H 2 O and 7.51gAl(NO 3 ) 3 9H 2 O dissolved in 100ml to remove CO 2 prepared in deionized water containing [Mg 2+ ]=1.2mol / L, [Al 3+ ]=0.6mol / L mixed salt solution; Weigh 6.4g of solid NaOH and dissolve it in 100ml to remove CO 2 Alkaline solution in deionized water.

[0032] (2). Use the nucleation crystallization isolation method to prepare the hydrotalcite precursor. Add the mixed salt solution and the mixed alkali solution in step (1) dropwise to the colloid mill at the same speed. The stirring speed of the colloid mill is 3000rmp, and the obtained The slurry was quickly transferred to a 500ml three-necked bottle, and the slurry was crystallized at 80°C for 8 hours under nitrogen protection, and then deCO2 2 Washed with deionized water to neutrality, the slurry-like intercalated hydrotalcite precursor Mg 3 Al-NO 3 -LDH.

[0033] (3). Disperse intercalated hydrotalcite precursor in CO removal 2 0.1mol / L suspens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com