Method for preparing large-diameter hollow fiber membrane and apparatus for implementing the method

A fiber membrane, large pore size technology, applied in the field of hollow fiber membrane and its preparation, can solve the problems of increasing the amount of solvent and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Such as figure 1 and 2 As shown, a conventional hollow fiber membrane wet spinning machine is used, the spinneret 4 is set inside the temperature and humidity control device 6 , and the supporting fiber 1 passes through the hollow cavity 608 of the temperature and humidity control device 6 . The hollow cavity 608 is provided with an air inlet and an air outlet, which are connected to the air inlet valve 604 and the air outlet valve 605 respectively, and the air inlet valve 604 is connected to the steam generator 603 . The walls of the hollow cavity 608 are jacketed with a water bath and connected to a liquid heating device 606 (for example realized by a liquid heating box). In addition, a temperature and humidity detector 602 is installed in the middle of the hollow cavity 608 and is connected to the temperature and humidity controller 601. The temperature and humidity controller 601 controls the inlet valve 604, the exhaust valve 605 and the temperature-controlled hea...

Embodiment 2

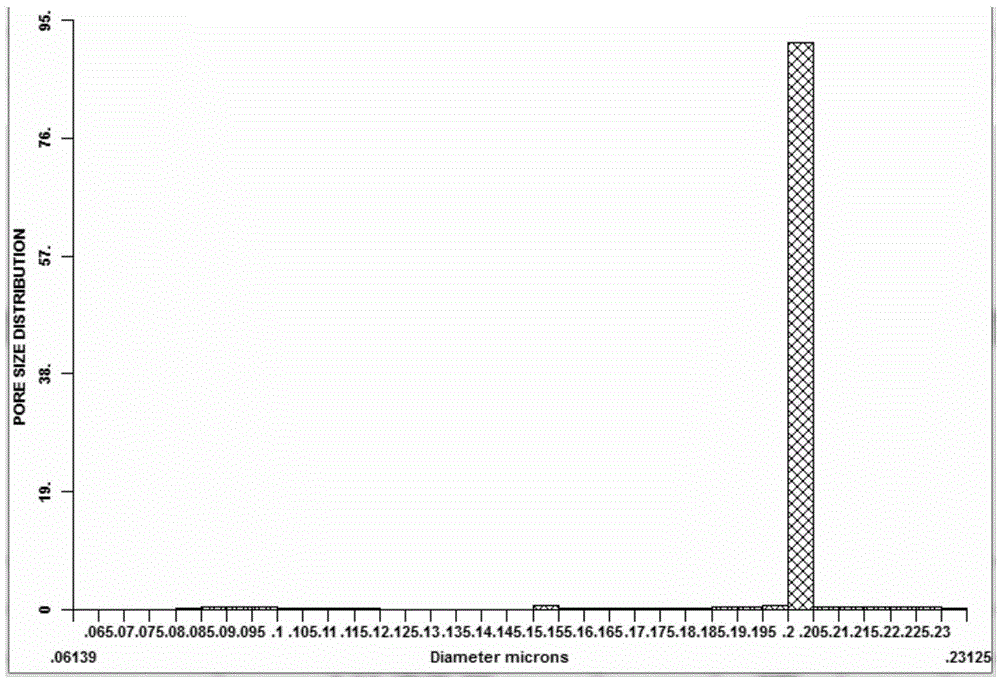

[0038] Wet spinning was carried out with the same formulation as in Example 1, except that the spinning was carried out at 70° C. and a humidity of 95% RH. The pure water flux of the obtained hollow fiber membrane is 3130L / m 2 .h, the average pore size of the membrane is 0.2 microns, such as Figure 4 .

Embodiment 3

[0043] Wet spinning was carried out with the same formula as in Example 1, except that the gel bath was 30% DMAC aqueous solution, and the coating was carried out at a dry range of 70° C. and a humidity of 95% RH.

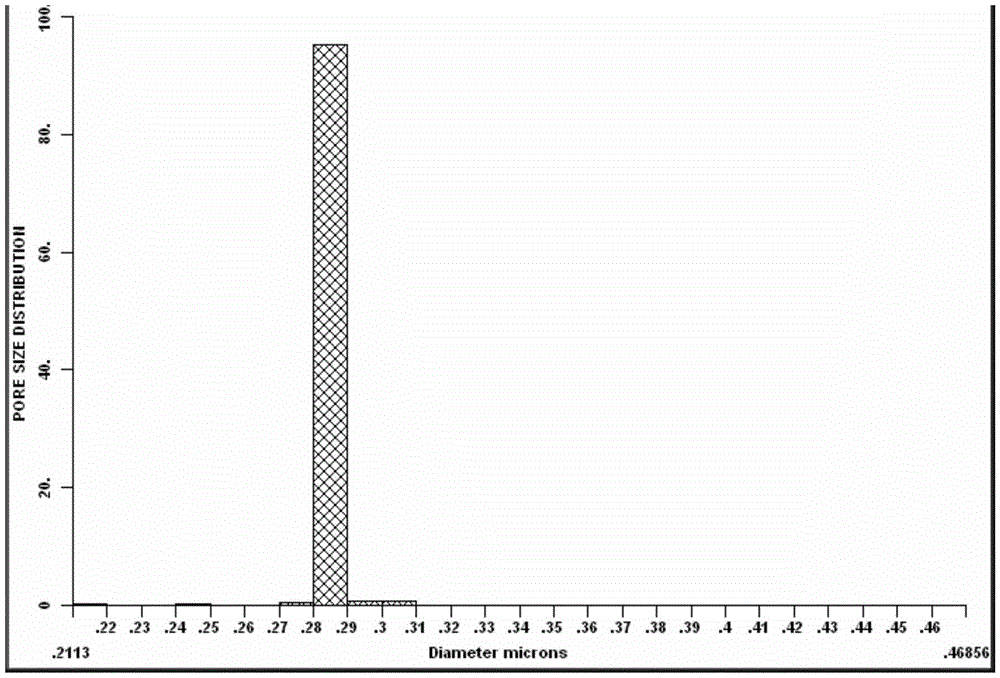

[0044] The pure water flux of the obtained hollow fiber membrane is 4600L / m 2 .h, the average pore size of the membrane is 0.28 microns, such as Figure 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com