Casting equipment and method for continuous production of controllable-density oxidation-free foamed aluminum sheets

A foamed aluminum, non-oxidation technology, applied in the field of metal materials, can solve the problems of uneven foam density of foamed aluminum boards and failure to meet the cooling conditions of foamed aluminum, and achieve the effect of uniform and controllable foam density and high-quality foam density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

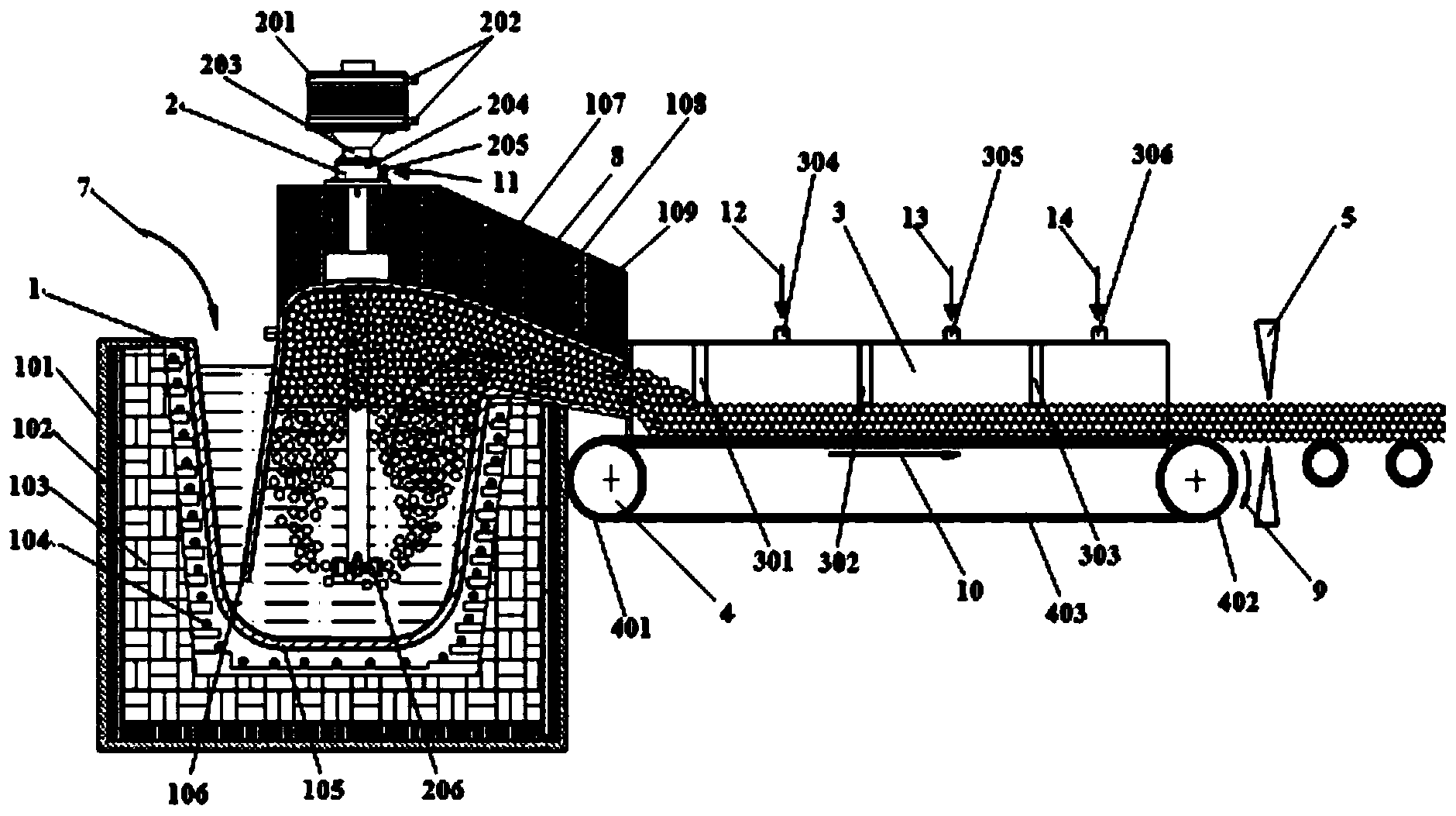

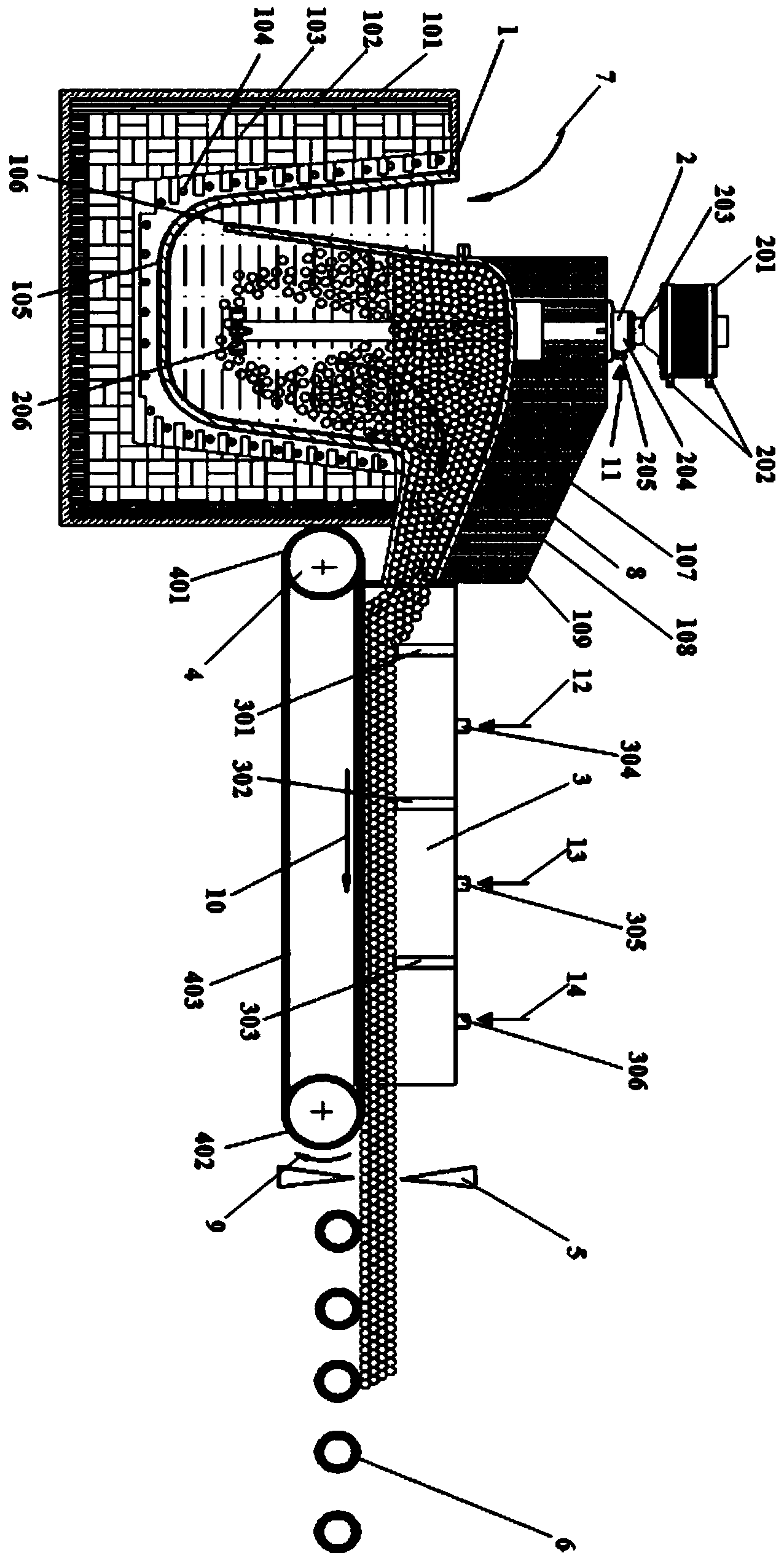

[0082] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

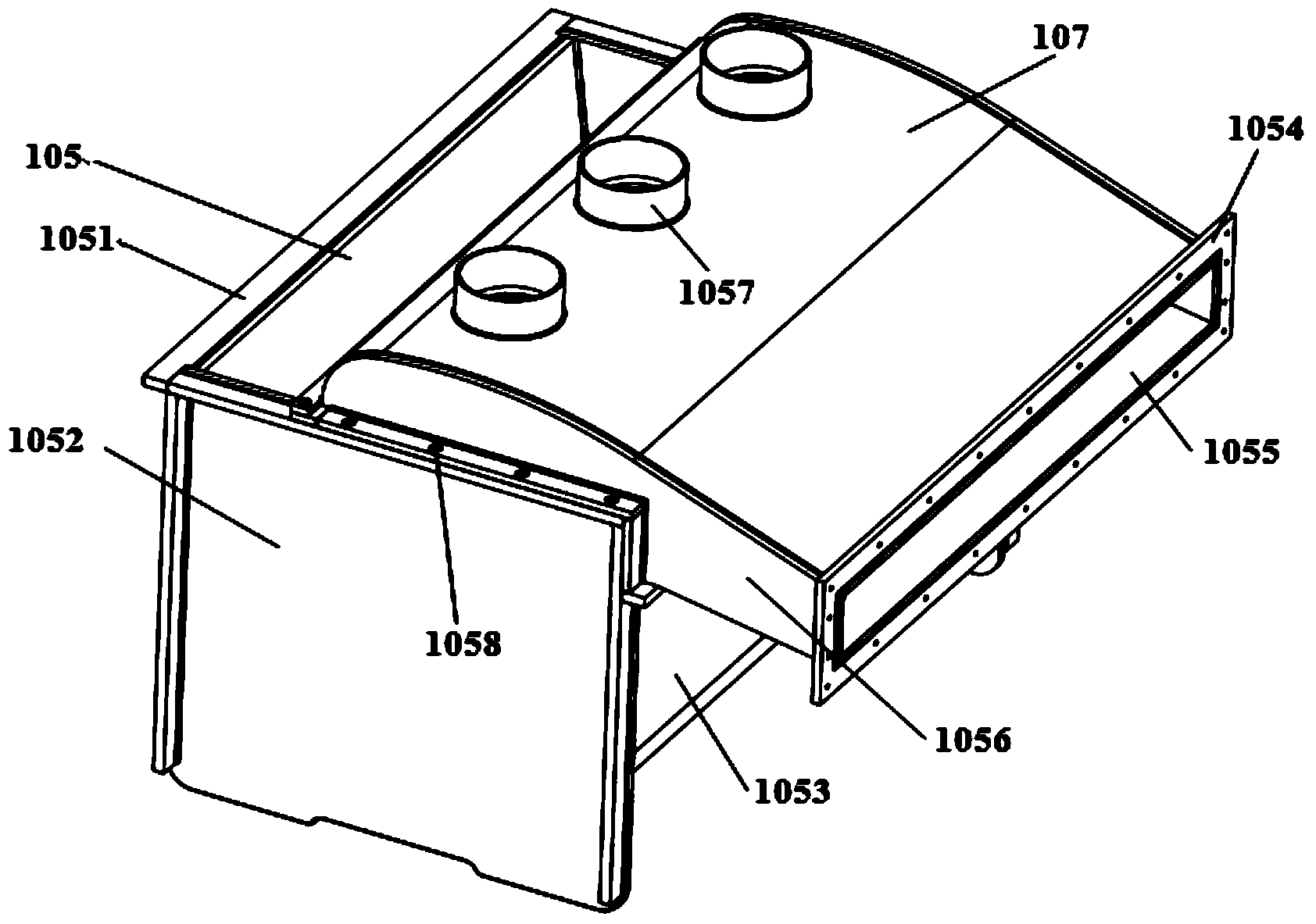

[0083]The embodiment of the present invention provides a casting device for continuous production of density-controllable and non-oxidized foamed aluminum sheets, which includes a resistance heating continuous foaming furnace 1, an air blowing mixer 2 installed on the foamed aluminum liquid guide cover, and a nitrogen cooling box 3 , steel belt conveyor 4, flying shear 5, and conveying roller table and other equipment, as well as nitrogen drying system and electrical control system (not shown, not as innovative content), are integrated according to the gas injection method and horizontal continuous casting technology without oxidation protection Realize the continuous production of large-size aluminum foam boards.

[0084] The specific structure of the continuous production density controllable non-oxidized aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com