Ultra white thin electronic glass and production method thereof

A production method and ultra-white and thin technology, which are applied in the field of glass production, can solve the problems such as the undisclosed method for clarifying liquid glass, and achieve the effect of reducing the generation of bubbles and quickly flattening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

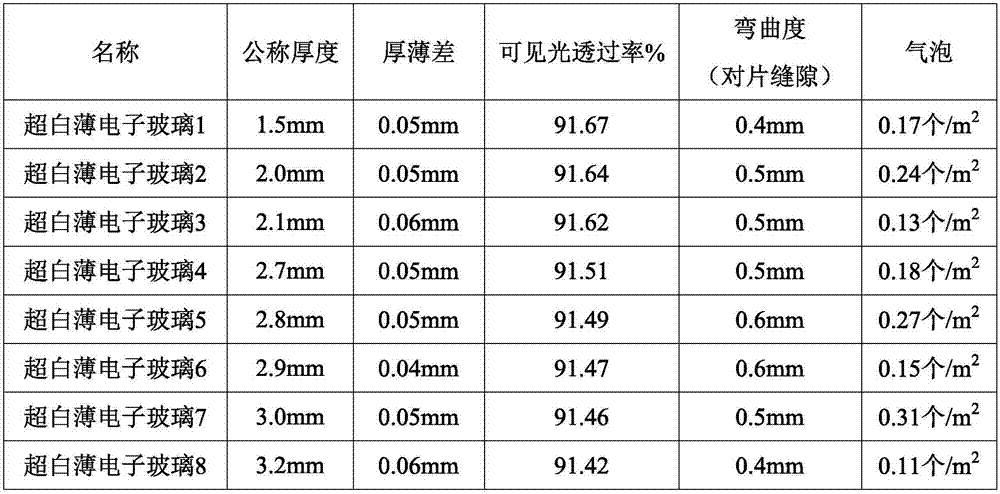

Examples

Embodiment 1

[0027] To produce ultra-white and thin electronic glass with a nominal thickness of 1.5 mm, the production process of ultra-white and thin electronic glass is carried out as follows.

[0028] The raw materials of ultra-white and thin electronic glass are composed of ultra-white and thin electronic glass basic components, clarifying agent components and decolorizing agent components. Wherein the basic components are as shown in Table 1:

[0029] Table 1 (parts by weight)

[0030] SiO 2

Na 2 O+K 2 o

KNO 3

CaO

MgO

al 2 o 3

Fe 2 o 3

co 2 o 3

72

14

1.554

10.5

1.5

0.444995

0.001

0.000005

[0031] Among the above-mentioned raw materials, the total amount of MgO and CaO is controlled at 12 parts by weight; Na 2 O+K 2 O+KNO 3 The total amount is controlled at 15.554 parts by weight. KNO 3 As a clarifying agent, the amount used is Na 2 O+K 2 11.1% of the total weight of O. Add CeO according...

Embodiment 2

[0038] To produce ultra-white and thin electronic glass with a nominal thickness of 2.8 mm, the production process of ultra-white and thin electronic glass is carried out as follows.

[0039] The raw materials of ultra-white and thin electronic glass are composed of ultra-white and thin electronic glass basic components, clarifying agent components and decolorizing agent components. Wherein the basic components are as shown in Table 2:

[0040] Table 2 (parts by weight)

[0041] SiO 2

Na 2 O+K 2 o

KNO 3

CaO

MgO

al 2 o 3

Fe 2 o 3

co 2 o 3

72

14

1.96

8.5

3

0.538496

0.0015

0.000004

[0042] Among the above-mentioned raw materials, the total amount of MgO and CaO is controlled at 11.5 parts by weight;2 O+K 2 O+KNO 3 The total amount is controlled at 15.96 parts by weight. KNO 3 As a clarifying agent, the amount used is Na 2 O+K 2 14% of the total weight of O. Add CeO according to 0.4% ...

Embodiment 3

[0049] To produce ultra-white and thin electronic glass with a nominal thickness of 3.2 mm, the production process of ultra-white and thin electronic glass is carried out as follows.

[0050] The raw materials of ultra-white and thin electronic glass are composed of ultra-white and thin electronic glass basic components, clarifying agent components and decolorizing agent components. Wherein the basic components are as shown in Table 3:

[0051] Table 3 (parts by weight)

[0052] SiO 2

Na 2 O+K 2 o

KNO 3

CaO

MgO

al 2 o 3

Fe 2 o 3

co 2 o 3

71.5

13

1.95

10

3

0.548495

0.0015

0.000005

[0053] Among the above-mentioned raw materials, the total amount of MgO and CaO is controlled at 13 parts by weight; 2 O+K 2 O+KNO 3 The total amount is controlled at 14.95 parts by weight. KNO 3 As a clarifying agent, the amount used is Na 2 O+K 2 15% of the total weight of O. Add CeO according to 0.45...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Nominal thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com