Degradable polyurethane wood-imitation material and preparing method thereof

A wood-like material and polyurethane technology, applied in the field of polyurethane, can solve problems such as toxicity, environmental pollution, and difficult degradation of polyurethane materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The degradable polyurethane imitation wood material is prepared as follows:

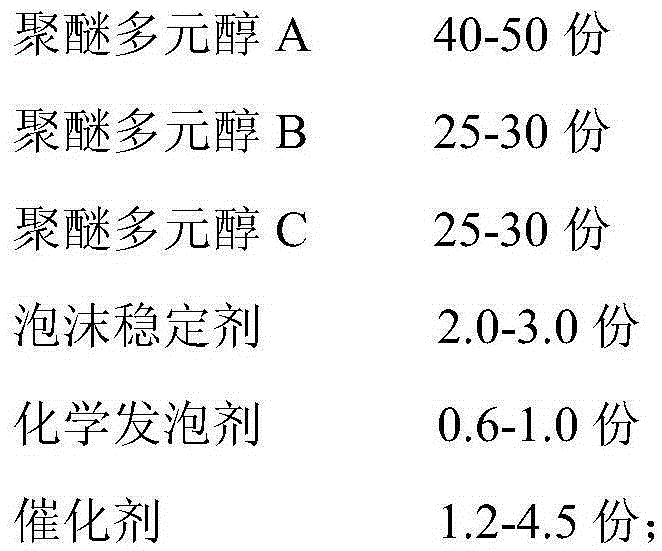

[0029] In parts by weight, component A:

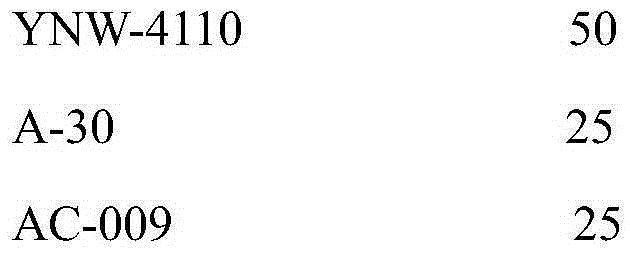

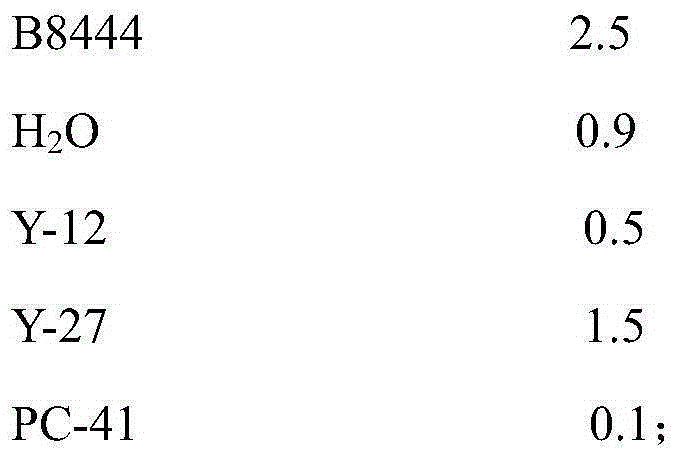

[0030]

[0031]

[0032] Component B:

[0033] Polymethylene polyphenylisocyanate.

[0034] The preparation method is as follows:

[0035] (1) Add YNW-4110, A-30, AC-009 into the reaction kettle and stir, then add B8444, H 2 O, Y-12, Y-27 and PC-41, stirred at room temperature for 10 minutes to obtain component A;

[0036] (2) Mix and react component A and component B according to the weight ratio of 1:1.1 to obtain a degradable polyurethane imitation wood material. The test results are shown in Table 1.

[0037] Table 1 embodiment 1 product detection index

[0038]

Embodiment 2

[0040] The degradable polyurethane imitation wood material is prepared as follows:

[0041] In parts by weight, component A:

[0042]

[0043] Component B:

[0044] Polymethylene polyphenylisocyanate.

[0045] The preparation method is as follows:

[0046] (1) Add YNW-4110, A-30, AC-009 into the reaction kettle and stir, then add B8444, H 2 O, PC-5, Y-27 and PC-41, stirred at room temperature for 20 minutes to obtain component A;

[0047] (2) Mix and react component A and component B according to the weight ratio of 1:1.1 to obtain a degradable polyurethane imitation wood material. The test results are shown in Table 2.

[0048] Table 2 embodiment 2 product detection index

[0049]

Embodiment 3

[0051] The degradable polyurethane imitation wood material is prepared as follows:

[0052] In parts by weight, component A:

[0053]

[0054] Component B:

[0055] Polymethylene polyphenylisocyanate.

[0056] The preparation method is as follows:

[0057] (1) Add YNW-4110, A-30, AC-009 into the reaction kettle and stir, then add B8444, H 2 O, PC-5, Y-27 and PC-41, stirred at room temperature for 30 minutes to obtain component A;

[0058] (2) Mix and react component A and component B according to the weight ratio of 1:1.1 to obtain a degradable polyurethane imitation wood material. The test results are shown in Table 3.

[0059] Table 3 embodiment 3 product detection index

[0060]

[0061] From Examples 1-3, it can be known that the obtained polyurethane imitation wood products have the characteristics of low density and high hardness, and it is completely possible to prepare imitation wood products with complex engraving patterns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com