Chemigum composite material for high-damping shock-insulation support and preparation method of chemigum composite material

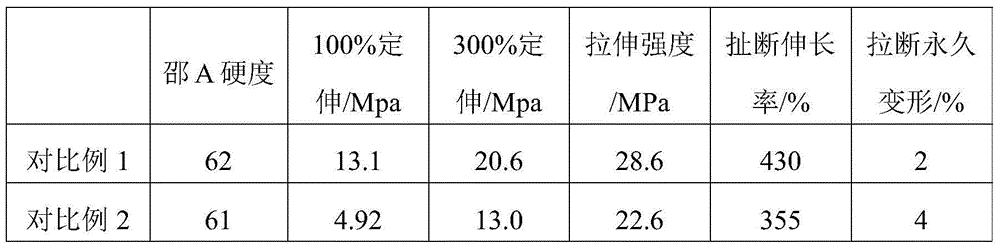

A technology of composite materials and nitrile rubber, which is applied in the field of rubber composite materials for high-damping shock-isolation bearings and its preparation, to achieve low elongation strength, small permanent deformation, and good physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

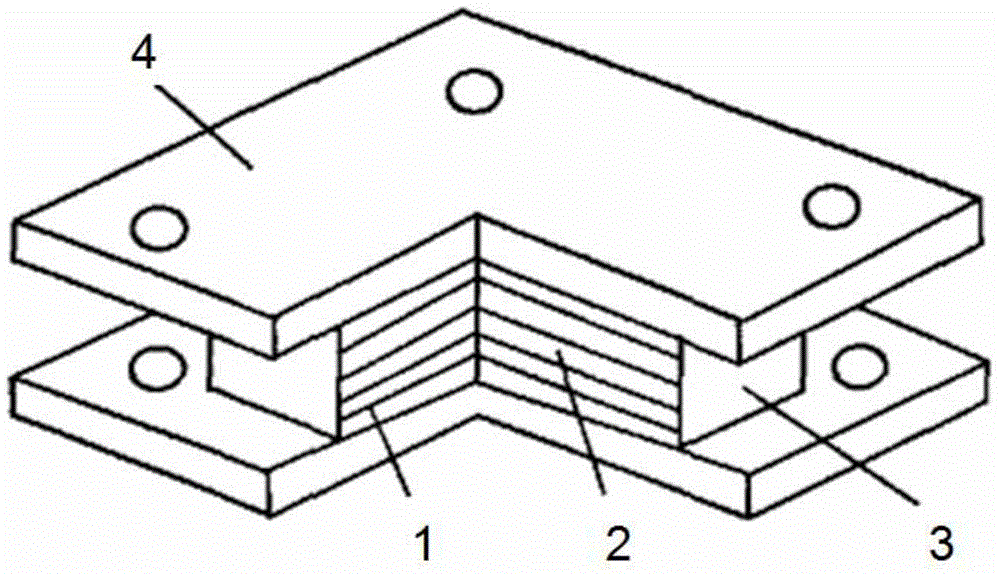

Image

Examples

Embodiment 1

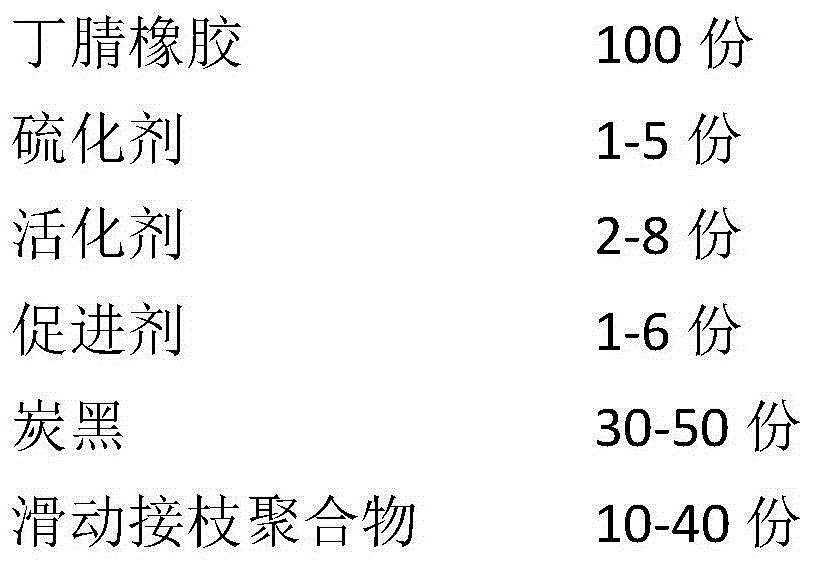

[0029] At 25°C, masticate 100g of nitrile rubber (the mass fraction of N220S acrylonitrile is 41%) on the open mill for 3 minutes, and then cover the rolls; add 5g of activator zinc oxide, 1g of activator stearic acid, and 1g of accelerator D , Accelerator DTDM 3g, carbon black N23440g, vulcanizing agent sulfur 2g mixed evenly, and prepared into a rubber compound; after thinning, add 20g of sliding graft polymer S100000 for pre-curing at 150°C for 3 hours, let it stand for 8 hours, At 160°C, vulcanize on a flat vulcanizer for 7.5 minutes to prepare a sliding graft polymer / nitrile rubber composite film.

Embodiment 2

[0031] At 25°C, masticate 100g of nitrile rubber (the mass fraction of N230S acrylonitrile is 35%) on the open mill for 3 minutes, and then cover the rolls; add 5g of activator zinc oxide, 1g of activator stearic acid, and 1g of accelerator D , Accelerator DTDM 3g, carbon black N23440g, vulcanizing agent sulfur 2g mixed evenly, and prepared into a rubber compound; after thinning, add 20g of sliding graft polymer S100000 for pre-curing at 150°C for 3 hours, let it stand for 8 hours, At 160°C, vulcanize on a flat vulcanizer for 13 minutes to prepare a sliding graft polymer / nitrile rubber composite film.

Embodiment 3

[0033] At 25°C, masticate 100g of nitrile rubber (the mass fraction of N240S acrylonitrile is 24%) on the open mill for 3 minutes, and then cover the rolls; add 5g of activator zinc oxide, 1g of activator stearic acid, and 1g of accelerator D , Accelerator DTDM 3g, carbon black N23440g, vulcanizing agent sulfur 2g mixed evenly, and prepared into a rubber compound; after thinning, add 20g of sliding graft polymer S100000 for pre-curing at 150°C for 3 hours, let it stand for 8 hours, At 160°C, vulcanize on a flat vulcanizer for 16.2 minutes to prepare a slide graft polymer / nitrile rubber composite film.

[0034] The formula of table 4 embodiment 1,2,3 rubber material

[0035] formula

Example 1

Example 2

Example 3

Nitrile rubber NBR

N220S 100 copies

N230S 100 copies

N240S 100 copies

Zinc oxide ZnO

5 copies

5 copies

5 copies

Stearic acid SA

1 copy

1 copy

1 copy

Accelerator D

1 copy

1 copy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com