Micro-nano-bubble generation device

A micro-nano bubble generation device technology, applied in the direction of transportation and packaging, mixers, mixing methods, etc., can solve the problems of poor continuous foaming ability, complex structure, substandard bubble size, etc., and achieve fast foaming speed, bubble High density, strong lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

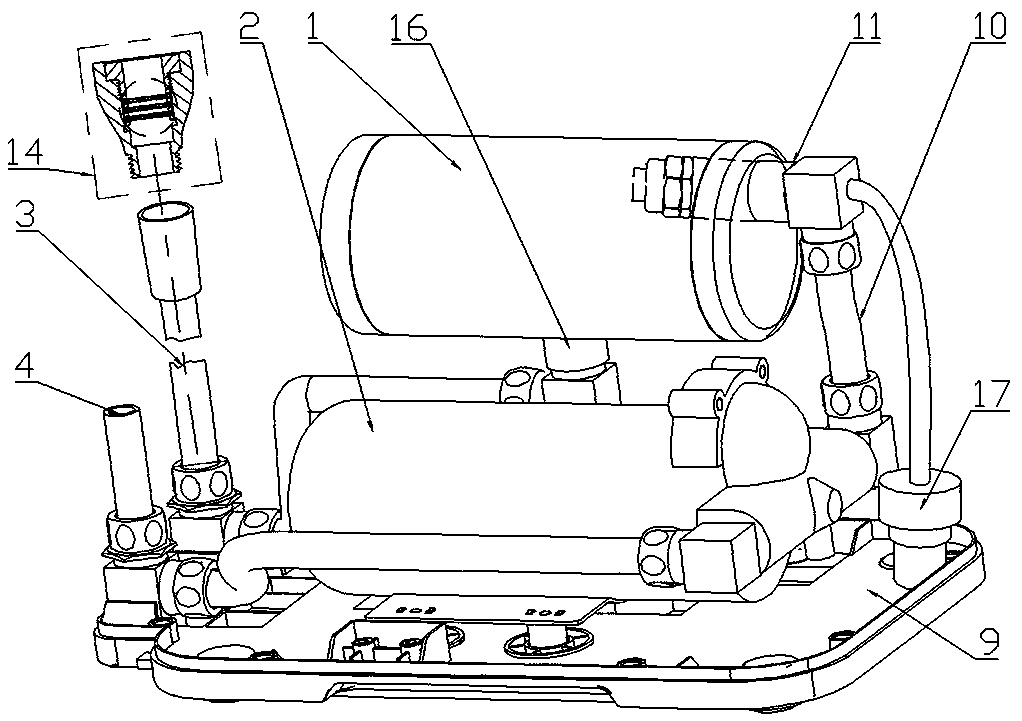

[0024] The micro-nano bubble generation device described in this embodiment, such as figure 1 As shown, it includes a base 9, a water inlet pipe 4, a booster pump 2, an air pump 17, a pressure tank 1, an outlet pipe 3 and an emulsifying nozzle 14, and the water inlet pipe 4 is connected to the booster pump 2, and the booster pump The pump 2 is installed on the base 9, the outlet of the booster pump 2 is provided with a connecting pipe 10, and the pressure tank 1 is provided with a flow control booster device 11, and the flow control booster device 11 is respectively connected to the connecting pipe 10 and the The air pump 17 is connected, and the bottom of the pressure tank 1 is provided with a water outlet 16, and the water outlet 16 communicates with the water outlet pipe 3, and the other end of the water outlet pipe 3 is connected with an emulsification nozzle 14.

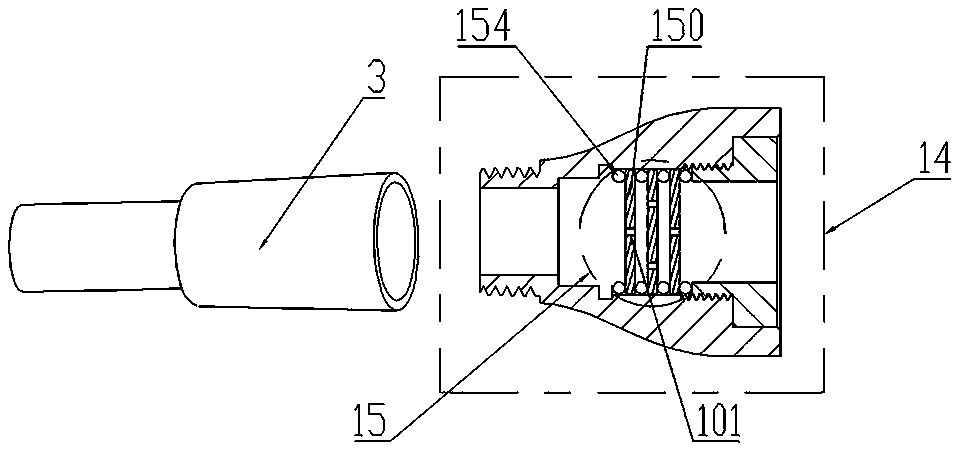

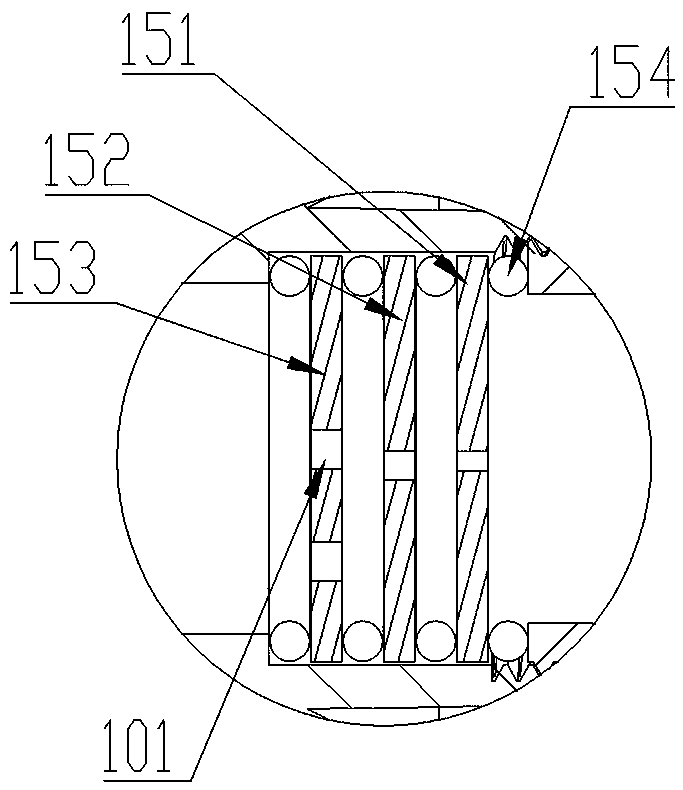

[0025] In order to ensure the foaming quality of micro-nano bubbles, such as figure 2 , image 3 As shown,...

Embodiment 2

[0030] The micro-nano bubble generation device described in this embodiment, such as Figure 4 As shown, in addition to the features described in Embodiment 1, in order to further improve the foaming quality and continuity, the connection between the booster pump 2 and the water inlet pipe 4 is also connected with an air inlet pipe 6, and the air inlet pipe 6 is provided with A one-way air intake valve 5 and an air volume regulating valve 8 are arranged at the connection between the air intake pipe 6 and the booster pump 2 .

[0031] In order to ensure the pressure of the gas and water mixture in the pressure tank 1, as Figure 5 As shown, the flow control supercharging device 11 is provided with a variable-diameter through hole 110, and the variable-diameter through hole 110 can be divided into an input end 111 with a larger inner diameter and connected to the connecting pipe 10, and an input end 111 with a smaller inner diameter and connected with the pressure. The output p...

Embodiment 3

[0034] The micro-nano bubble generation device described in this embodiment, such as Image 6 , Figure 7 As shown, in addition to the features described in Embodiment 2, in order to prevent impurities from entering the foaming device and cause malfunctions, and to facilitate the recycling of bubble water, the water inlet end of the water inlet pipe 4 is connected with a water inlet connector 13, and the water inlet connector 13 includes the water inlet upper body 134, the water inlet lower body 130, the filter core body 131, the pre-filter 132 and the decorative ring 133; the water inlet upper body 134 is threaded with the water inlet lower body 130, and the filter core body 131, The front filter screen 132 and the decorative ring 133 are arranged on the upper body 134 of the water inlet and the lower body 130 of the water inlet; Image 6 , the outer side of the filter body 131 is sequentially connected with the front filter 134 and the decorative ring 133 from the inside to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com