Prefoaming machine for foam pad plate preparation

A technology for pre-foaming and foam pads, applied in the field of pre-foaming machines for the preparation of foam pads, can solve the problems of low foaming efficiency, inconvenient pressure adjustment, insufficient safety, etc. novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

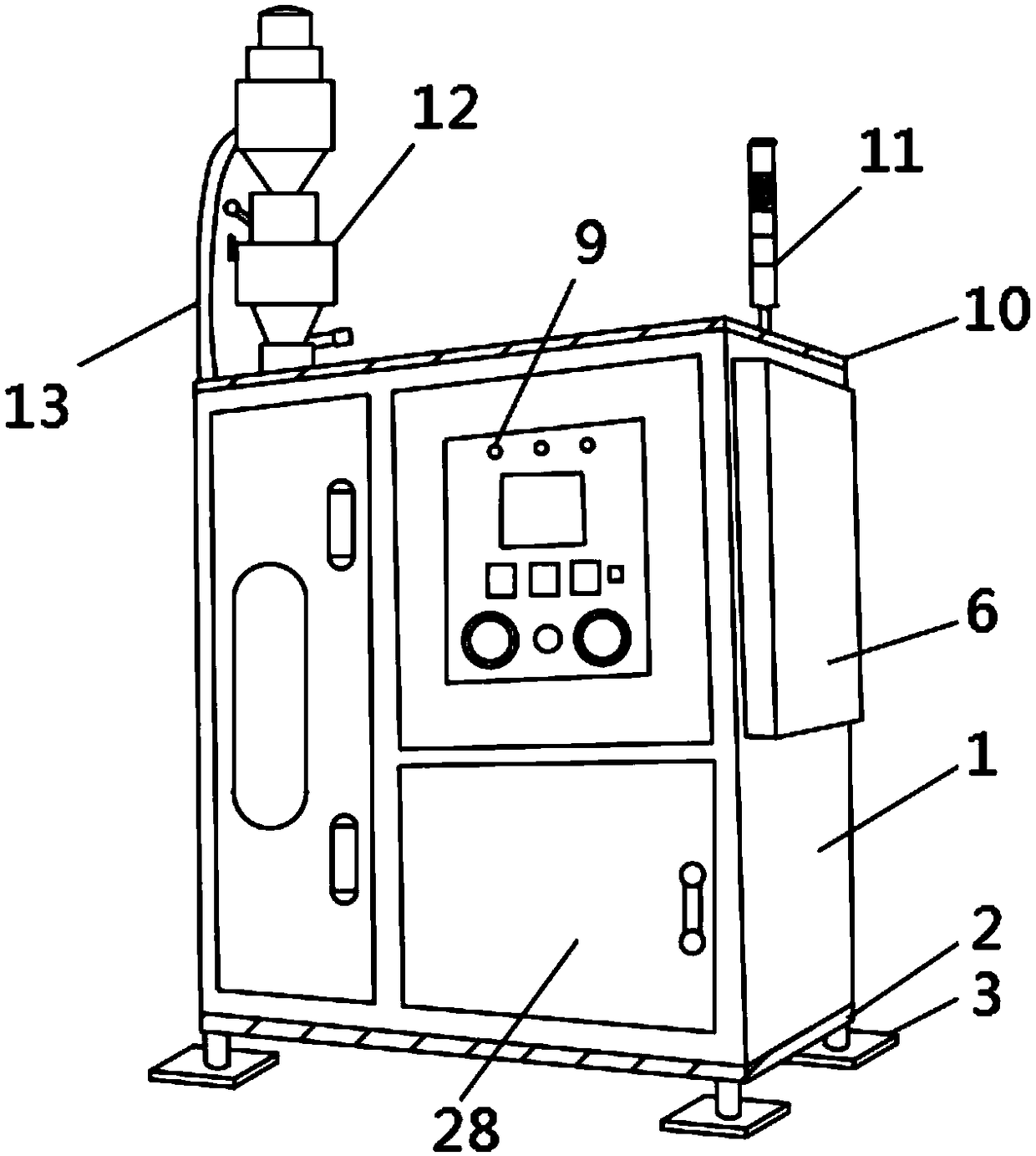

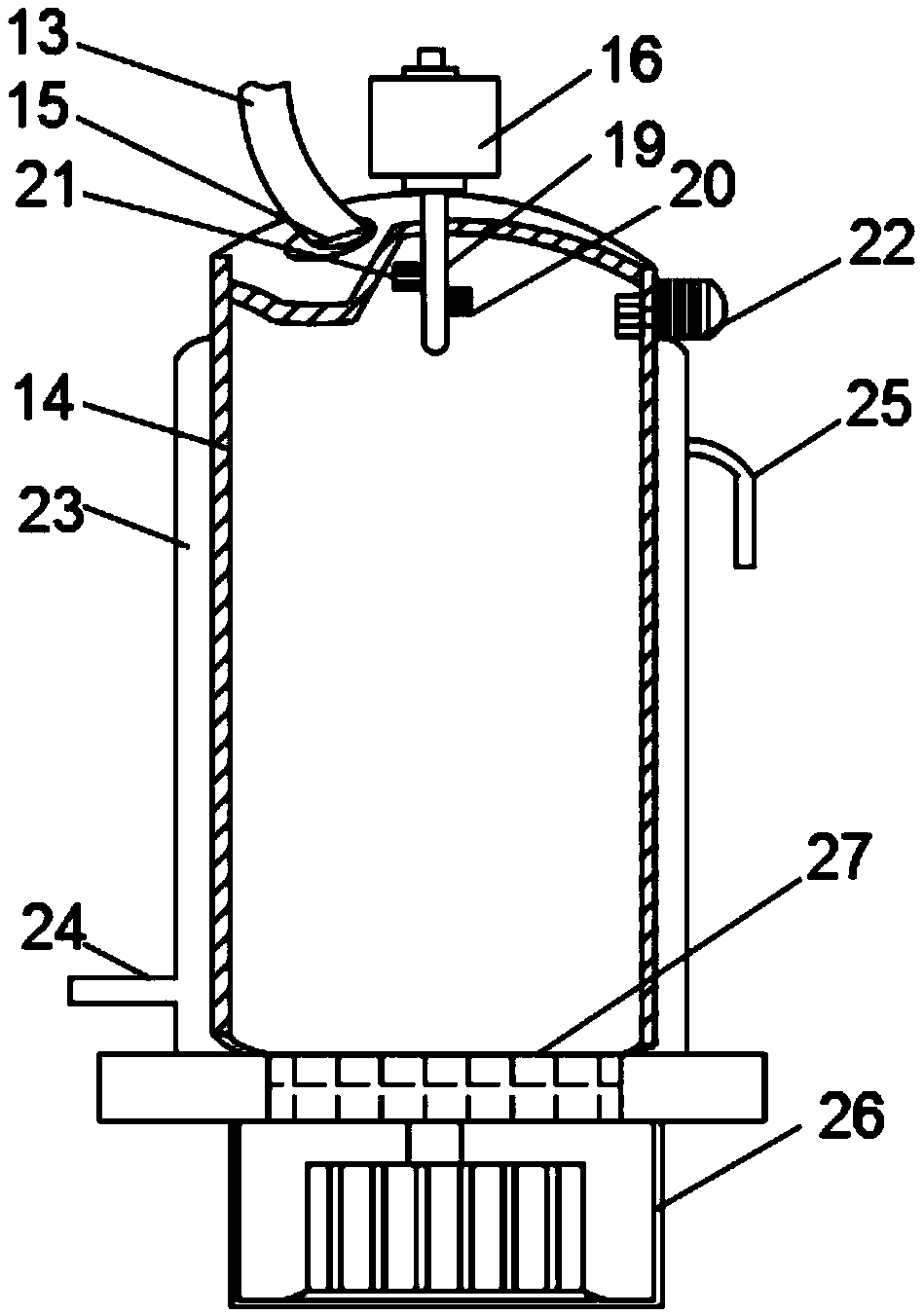

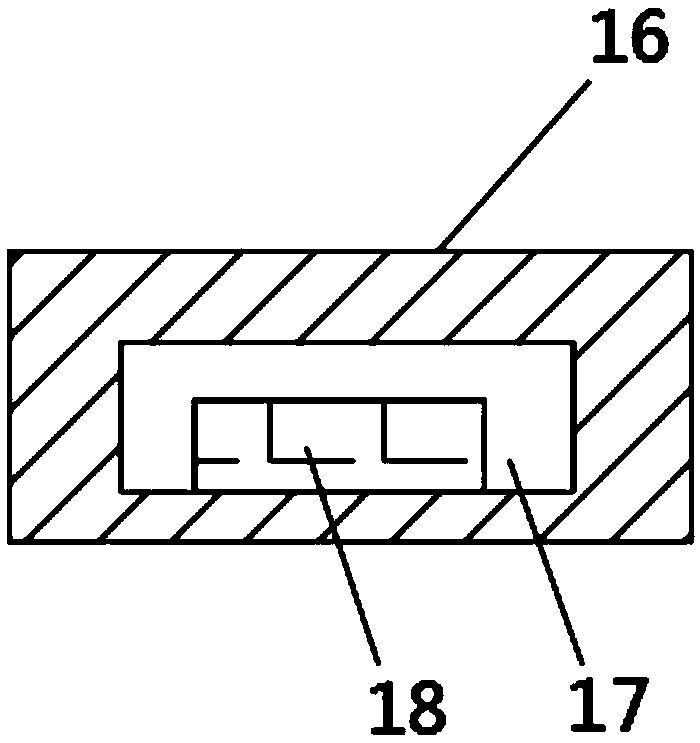

[0019] Embodiment one, by figure 1 , figure 2 , image 3 and Figure 4 Given, the present invention includes a pre-foaming machine body 1, the bottom end of the pre-foaming machine body 1 is provided with a bottom fixing plate 2, the bottom end of the bottom fixing plate 2 is provided with a support foot 3, and the bottom end of the bottom fixing plate 2 is close to The position of the support foot 3 is provided with a groove 4, the inside of the bottom fixed plate 2 is located at the top of the groove 4, and a hydraulic cylinder 5 is arranged, and the bottom end of the hydraulic cylinder 5 is located inside the groove 4, and a first support rod 6 is arranged. The bottom end of a support rod 6 is provided with a roller 7, and the roller 7 is connected with the first support rod 6 through a roller support frame 8. One side of the pre-foaming machine body 1 is provided with a control board 9, and the input end of the control board 9 It is electrically connected to the mains,...

Embodiment 2

[0021] Embodiment two, on the basis of embodiment one, by figure 2 and image 3 Given, the outside of the foaming tank 14 is provided with a U-shaped heating tube 23, one end of the U-shaped heating tube 23 is provided with a liquid inlet 24, the other end of the U-shaped heating tube 23 is provided with a liquid outlet 25, and the bottom of the foaming tank 14 A heater 26 is arranged at the top of the heater 26, and a heat conduction plate 27 is arranged on the top of the heater 26. The temperature sensor 21 is electrically connected to the input end of the controller 18, and the output end of the controller 18 is electrically connected to the heater 26. When in use, the liquid inlet 24 Inject hot water into the U-shaped heating pipe 23, and the hot water is exported through the liquid outlet 25, so that the foaming tank 14 can be heated, and the foaming efficiency can be improved. At the same time, the temperature inside the foaming tank 14 can be sensed by the temperature ...

Embodiment 3

[0022] Embodiment three, on the basis of embodiment one, by Figure 5 Provided, one side of the bottom of the pre-foaming machine body 1 is provided with a locker 28, the top inside the locker 28 is provided with a support plate 29, the middle part of the support plate 29 is provided with a partition plate 30, and the two sides of the partition plate 30 Both ends are provided with a first slider 31, the inner wall of the locker 28 and the top of the support plate 29 are provided with a first slide rail 32 at the position corresponding to the first slider 31, and the middle part of the locker 28 is provided with a movable Plate 33, moving plate 33 two ends are all provided with the second slide block 8, and the position place that the inner wall of locker 28 is provided with the second slide block 34 is all provided with the second slide rail 35, when using, through locker 28 , can make the whole have a certain storage function, and the functions are diverse. At the same time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com