Foam composition, polyurethane plastic, and preparation method and application of polyurethane plastic

A technology of composition and polyurethane, which is applied in the field of foam composition, can solve the problems of polyester rigid foam and base material, insufficient strength of fluid foam, high thermal conductivity, limited application range, etc., to achieve Strong cohesive force, high foam strength and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

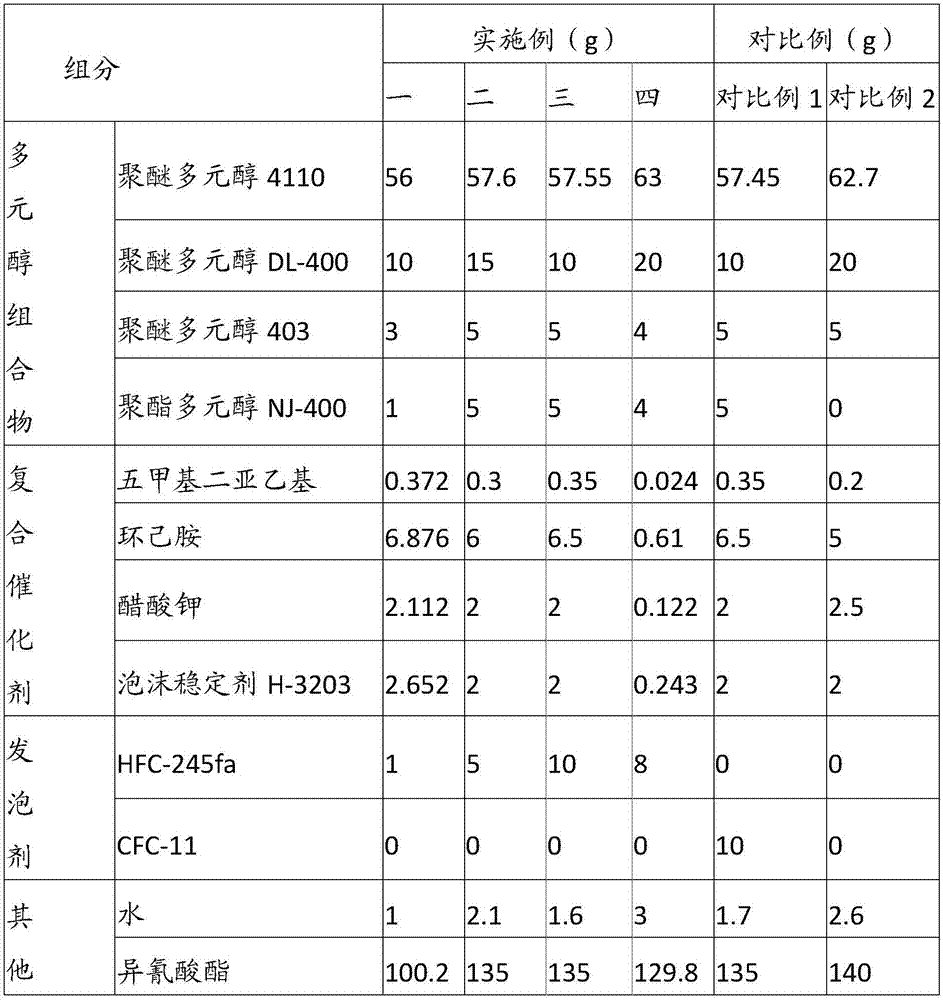

[0048] In the present invention, the preparation method of embodiment 1,2,4 is:

[0049] (1) Mix and stir polyether polyol YD-4110, polyether polyol DL-400, polyether polyol YD-403 and / or polyester polyol NJ-400, composite catalytic promoter and water, and then Add foaming agent HFC‐245fa at 20°C and mix evenly to obtain a foam composition;

[0050] (2) Mix and stir the isocyanate and the foam composition obtained in step (1) evenly to obtain polyurethane plastic.

Embodiment 3

[0051] The difference between the preparation methods of Example 3 and Examples 1, 2, and 4 is that the foaming agent HFC-245fa is added at a temperature of 15° C. in step (1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com