Flame-retardant composite polyether for on-site spraying

A combination of polyether and on-site technology, which is applied in the field of main raw materials of polyurethane rigid foam, can solve the problems of difficult production and achieve the effects of low cost, fast curing and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with specific examples, but the present invention is not limited to the specific examples.

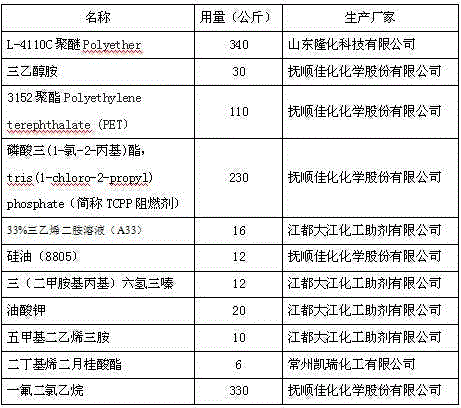

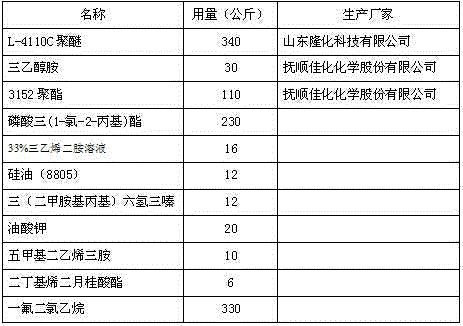

[0009] On-site spraying flame retardant combination polyether, the formula is as follows:

[0010]

[0011] Add various raw materials into the single-screw mixing tank in proportion, the order of addition should be to add fluorodichloroethane at the end, and other raw materials should be added in any order, keep the room temperature between 15 degrees and 25 degrees, after all the materials are added, turn on the stirring device , stirred for 10 minutes, then stood still for 10 minutes, stirred for another 20 minutes, and finally filtered for use.

[0012] During construction, use black material for polyurethane foaming, with an oxygen index of 30 and a free foam density of 40.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com