Novel superfast train by utilizing ground effect pneumatic suspension and electromagnetic propulsion

A pneumatic levitation and electromagnetic propulsion technology, applied to motor vehicles, road vehicles, etc., can solve the problem of large power consumption, achieve the effects of reducing weight, improving efficiency, and improving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

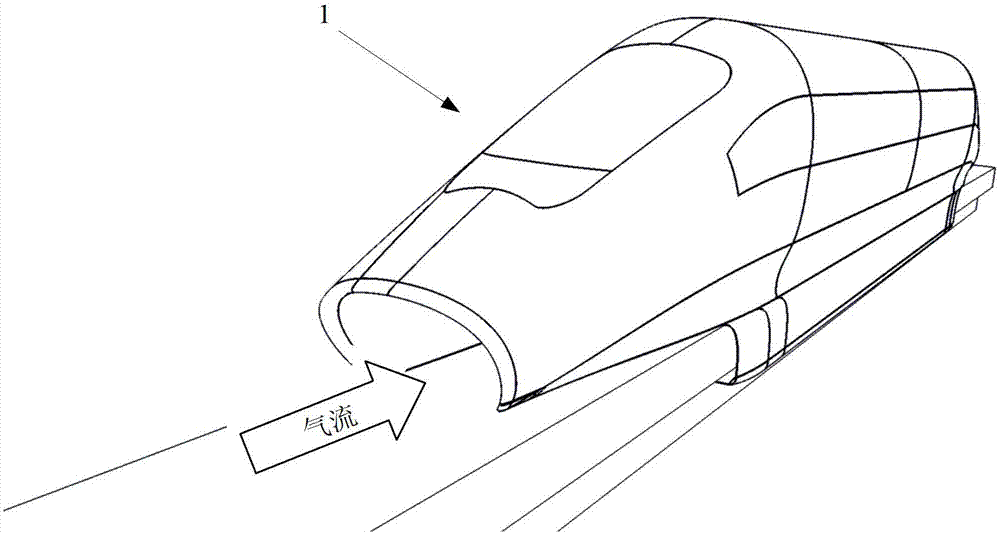

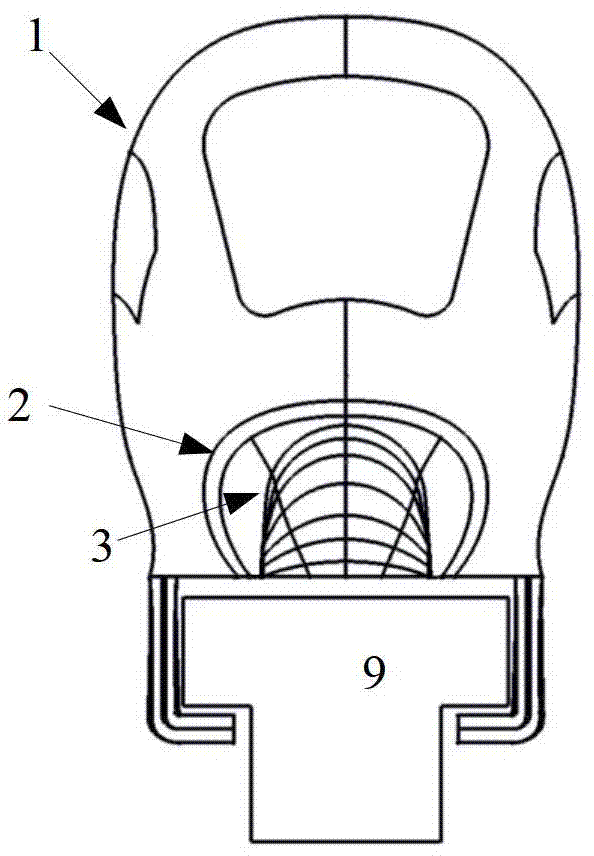

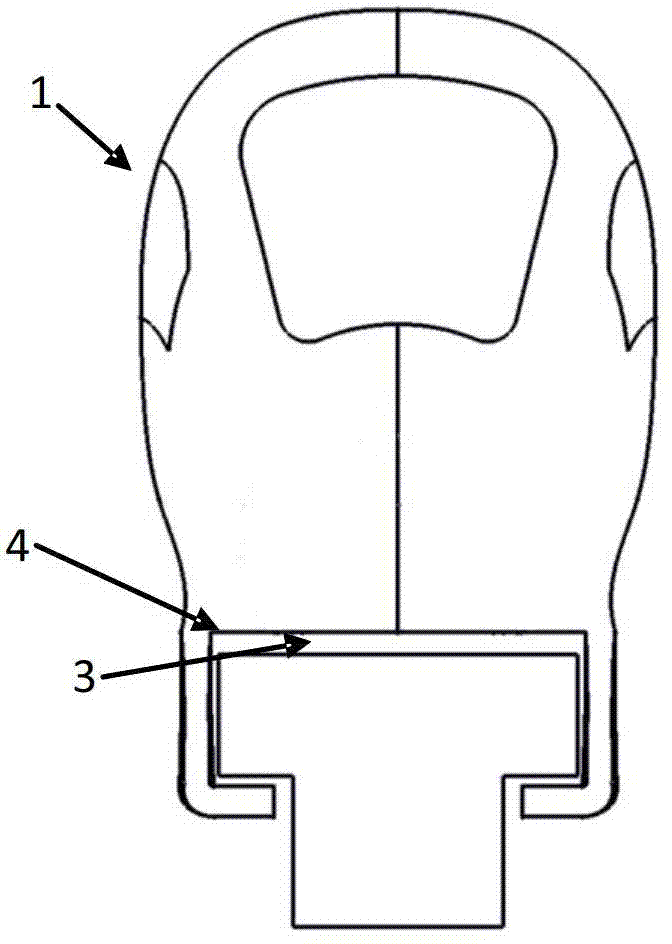

[0015] see figure 1 , Figure 2a and Figure 2b , the ultra-high-speed train described in the present invention is a single-section train form with a length of about 75m. When running at high speed, part of the incoming flow will enter the airflow channel 3 at the bottom of the train through the entrance 2 at the front end of the train 1. The cross-sectional area of the inlet 2 of the undercarriage 3 is relatively large, and the cross-sectional area of the outlet 4 is very small. The air flow can form a relatively high pressure zone in the air flow passage 3 .

[0016] see Figure 3a and Figure 3b , the bottom of the super high-speed train described in the present invention is made up of a contracted curved surface 5 and two planes 6 . The curved surface 5 is formed by the upward arching of the bottom surface of the vehicle, and together with the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com