An asymmetric double permanent magnet hybrid excitation switch flux linkage linear motor

A technology of mixed excitation and switching flux linkage, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of difficult adjustment of the magnetic field and unfavorable high-speed operation of the motor, so as to reduce mutual inductance, ensure constant power operation range of weak magnetic field, avoid competing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

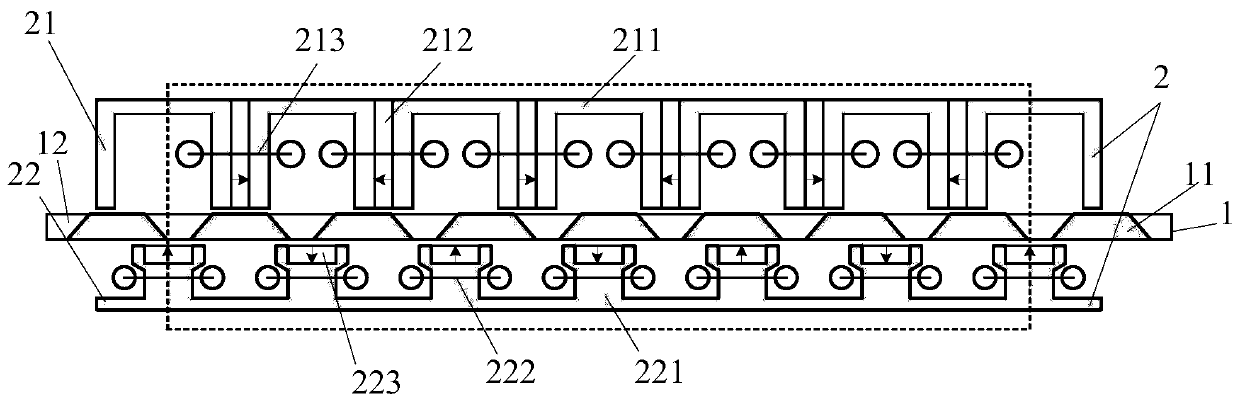

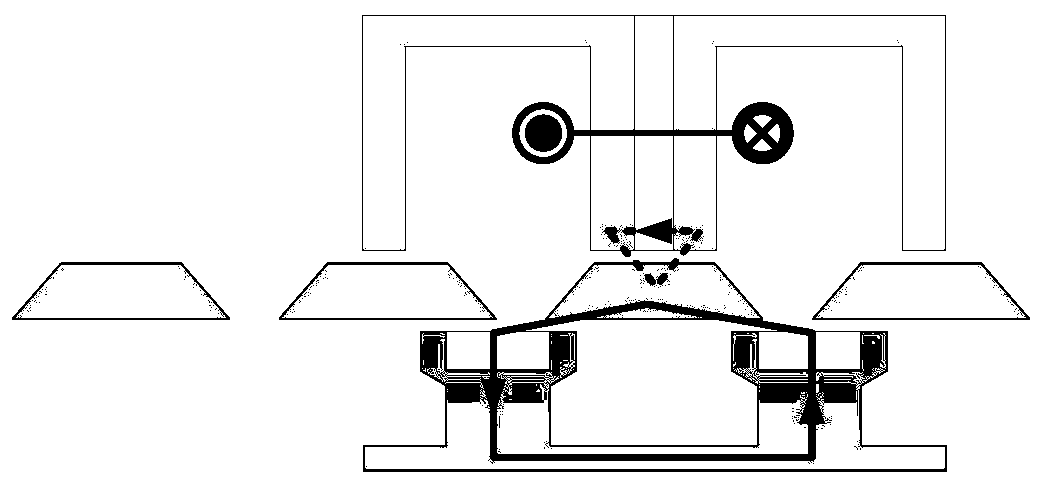

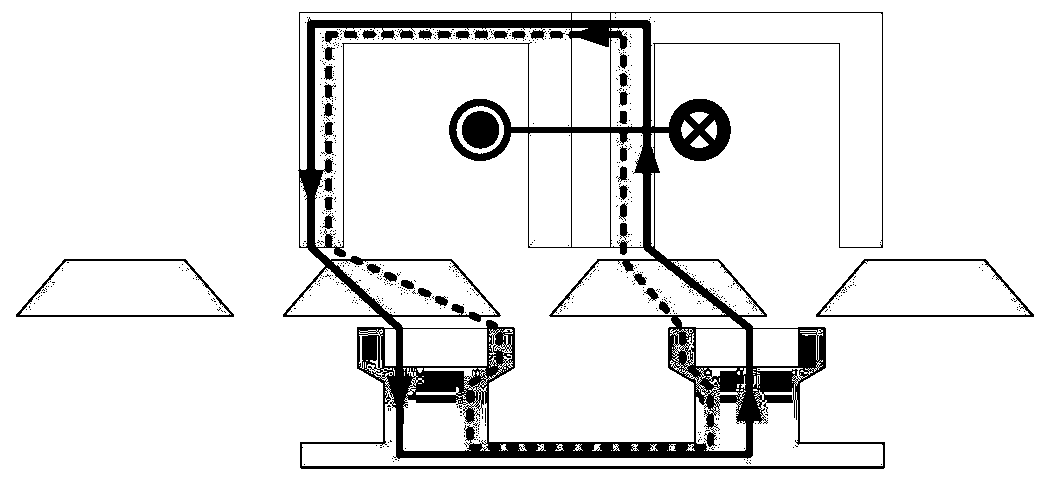

[0030] Such as figure 1 As shown, the asymmetric double permanent magnet hybrid excitation switch flux linkage linear motor of this embodiment includes a long stator 1 and a short mover 2, the short mover 2 includes primary I and primary II, and primary I includes a U-shaped armature Iron core 211, permanent magnet I, armature winding 213, primary II includes excitation core 221, excitation winding 222 and permanent magnet II; permanent magnet I is arranged alternately, and the magnetization direction of adjacent permanent magnet I is opposite, and the magnetization direction is the same as The direction of movement is consistent, the primary I and primary II are fixed on the mobile platform, the two are relatively stationary, and both maintain a certain air gap with the long stator 1. The permanent magnet II is embedded in the field teeth of the field core 221, and the field winding 222 is set on the salient pole of the field core 221 to form a field pole. The polarity of the...

Embodiment 2

[0036] Figure 4 The structure shown is a deformed structure of Embodiment 1, and figure 1 The difference is that the magnetic isolation bridge 214 is added, so that the primary I stamping pieces are connected as a whole, avoiding the repulsive force between adjacent permanent magnet poles to cause installation difficulties and facilitate processing. The disadvantage is that part of the permanent magnet I is inevitably short-circuited. flux linkage, reducing thrust density

Embodiment 3

[0038] Such as Figure 5 As shown, this embodiment is another modified structure for the first embodiment. By adding fault-tolerant teeth 215 in the armature slots, the degree of coupling between adjacent coils can be reduced, thereby reducing the coupling between adjacent coils. Mutual inductance is beneficial to improve the fault tolerance performance of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com