High-speed magnetic levitation linear electromagnetic propulsion system

A linear electromagnetic and propulsion system technology, which is applied in the propulsion system, the holding device using magnetic attraction or thrust, and electrical components, etc., can solve the problems of difficult suspension control, high circuit requirements, and high vehicle weight, and achieves light weight and operation. High efficiency and small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

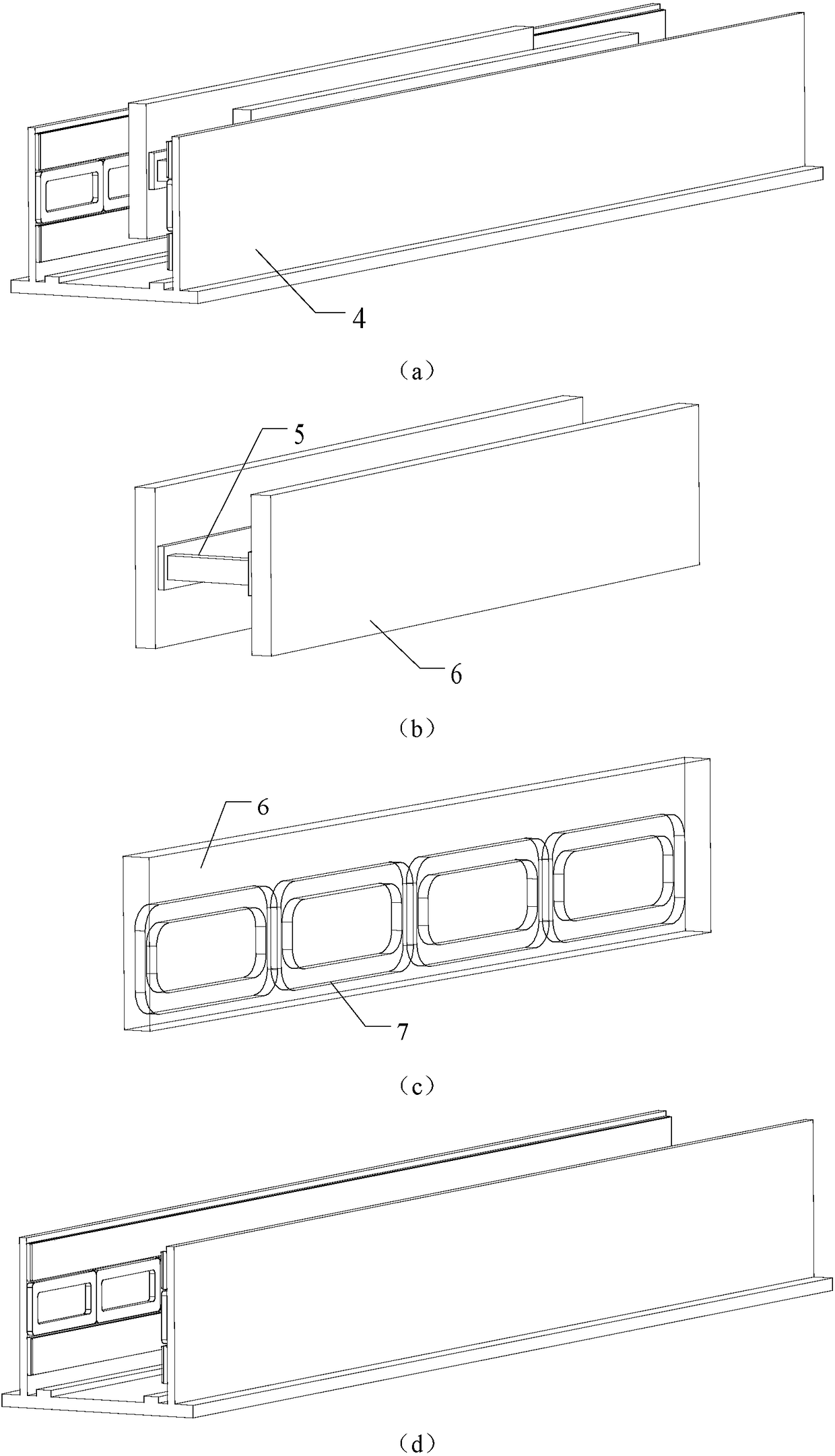

[0030] Specific implementation mode one: combine figure 1 Specifically explaining this embodiment, the high-speed maglev linear electromagnetic propulsion system described in this embodiment is mainly composed of a drive control subsystem and a levitation guidance and propulsion subsystem. The drive control subsystem is mainly composed of a power converter and a controller. The power converter is used to provide driving energy, and the controller is used to control the moving speed of the mover, the position of the mover, and the current of the primary coil 3 . The suspension guidance and propulsion subsystem is mainly composed of stator and mover. The stator is fixed on the ground and is mainly composed of a suspension guiding primary and a propulsion primary; the mover is installed on a skid car 5 and is mainly composed of a cryogenic container 6 and a superconducting coil 7 or a superconducting block. The superconducting coil 7 or a superconducting block The material is i...

specific Embodiment approach 2

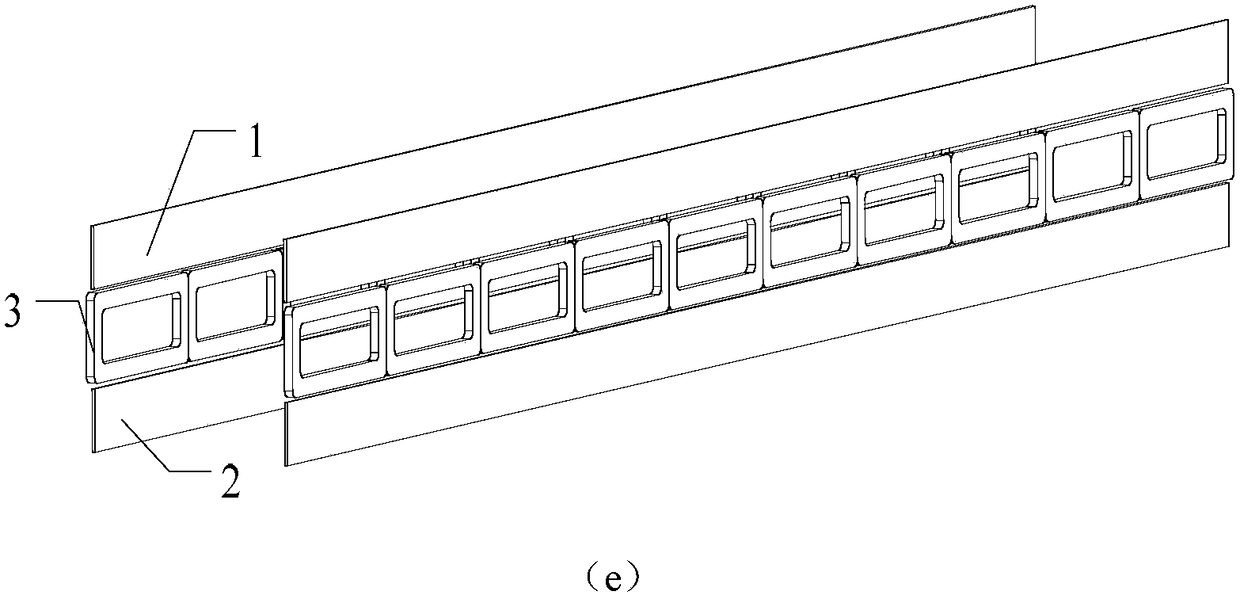

[0035] Specific implementation mode two: combination figure 2 Specifically explain this embodiment, the high-speed maglev linear electromagnetic propulsion system described in this embodiment, the high-speed maglev linear electromagnetic propulsion system is mainly composed of a drive control subsystem and a levitation guidance and propulsion subsystem. The drive control subsystem is mainly composed of a power converter and a controller. The power converter is used to provide driving energy, and the controller is used to control the moving speed of the mover, the position of the mover, and the current of the primary coil 3 . The suspension guidance and propulsion subsystem is mainly composed of stator and mover. The stator is fixed on the ground and is mainly composed of a suspension guiding primary and a propulsion primary; the mover is installed on a skid car 5 and is mainly composed of a cryogenic container 6 and a superconducting coil 7 or a superconducting block. The su...

specific Embodiment approach 3

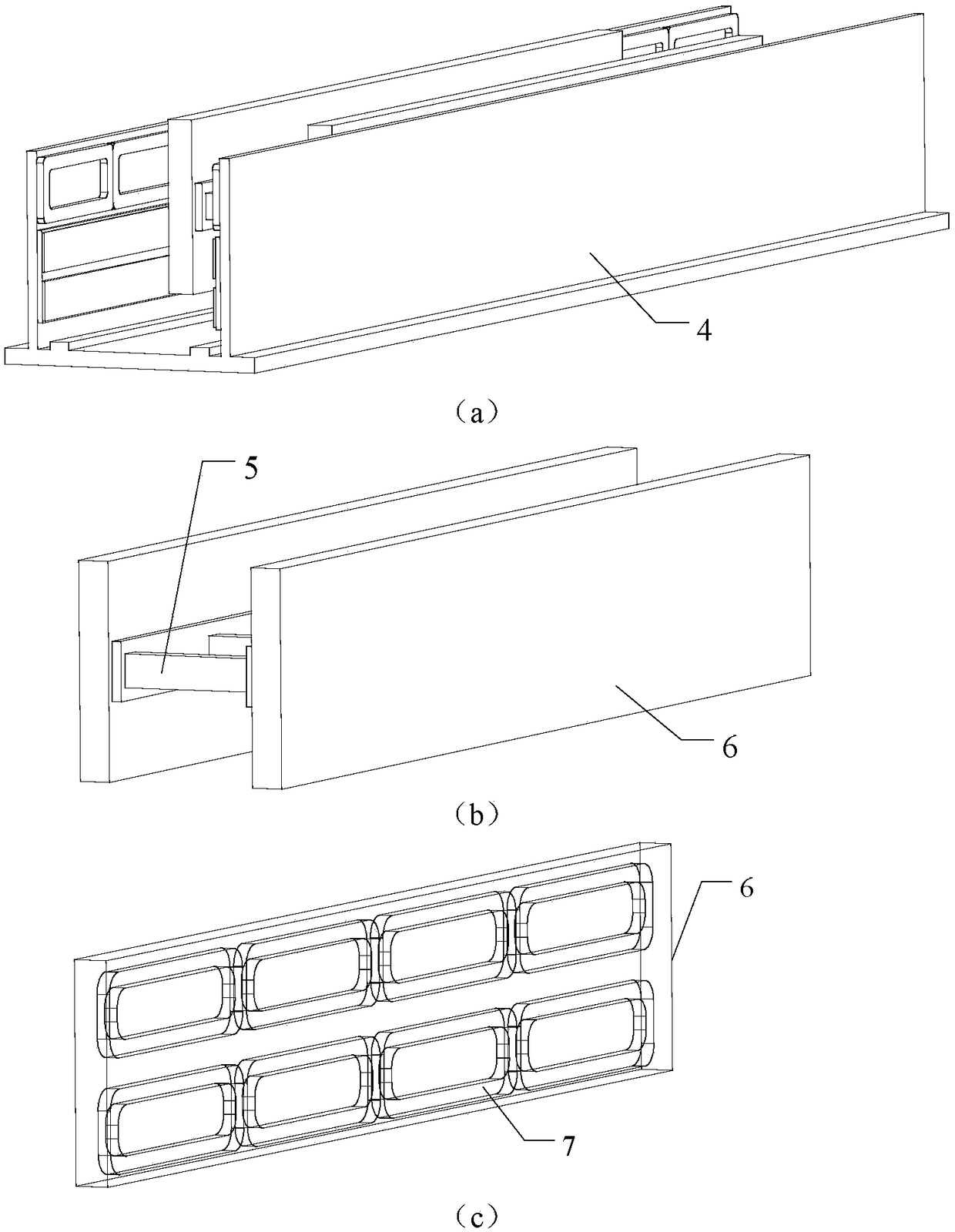

[0040] Specific implementation mode three: combination image 3 Specifically explain this embodiment, the high-speed maglev linear electromagnetic propulsion system described in this embodiment, the high-speed maglev linear electromagnetic propulsion system is mainly composed of a drive control subsystem and a levitation guidance and propulsion subsystem. The drive control subsystem is mainly composed of a power converter and a controller. The power converter is used to provide driving energy, and the controller is used to control the moving speed of the mover, the position of the mover, and the current of the primary coil 3 . The suspension guidance and propulsion subsystem is mainly composed of stator and mover. The stator is fixed on the ground and is mainly composed of a suspension guiding primary and a propulsion primary; the mover is installed on a skid truck 5 and is mainly composed of a permanent magnet array 8 , a shielding conductor plate 9 , and a damping conductor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com