Needle type porous material emitter array type mini-type field emission electric thruster

A technology of porous materials and electric thrusters, which is applied in the direction of thrust reversers, plasma utilization, machines/engines, etc., can solve the problems of long launch needles, short life of thrusters, and low space utilization, and achieve size reduction and The effect of weight, high thrust density and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] single gate

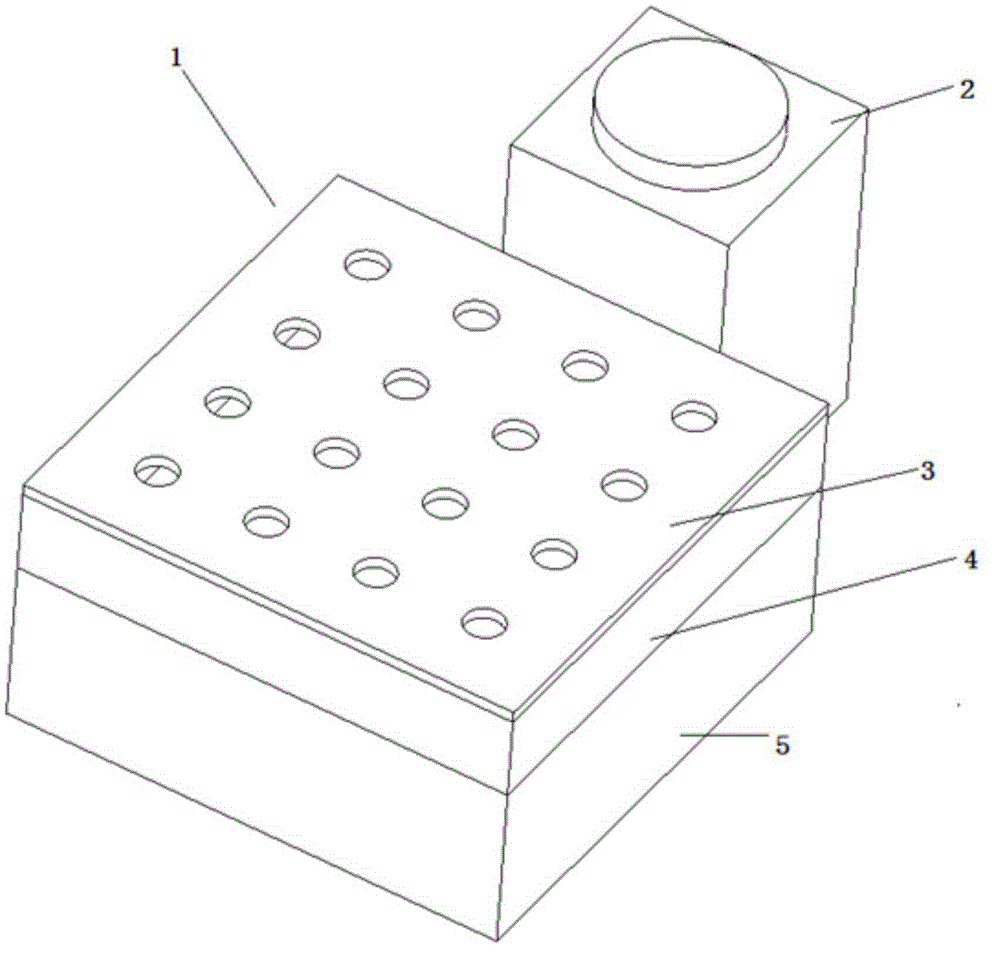

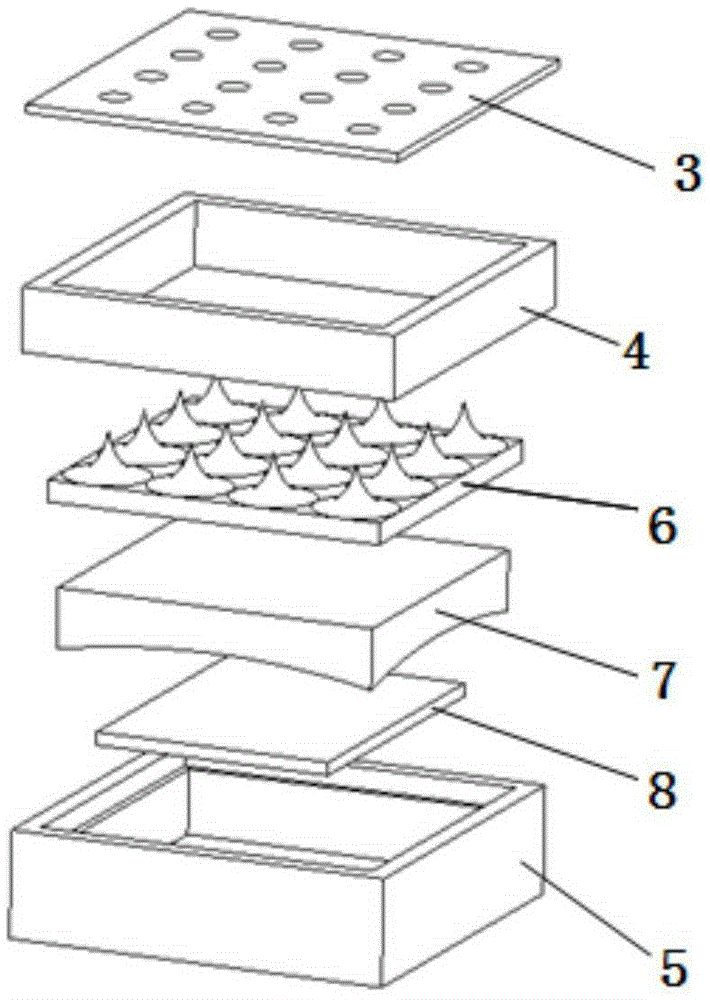

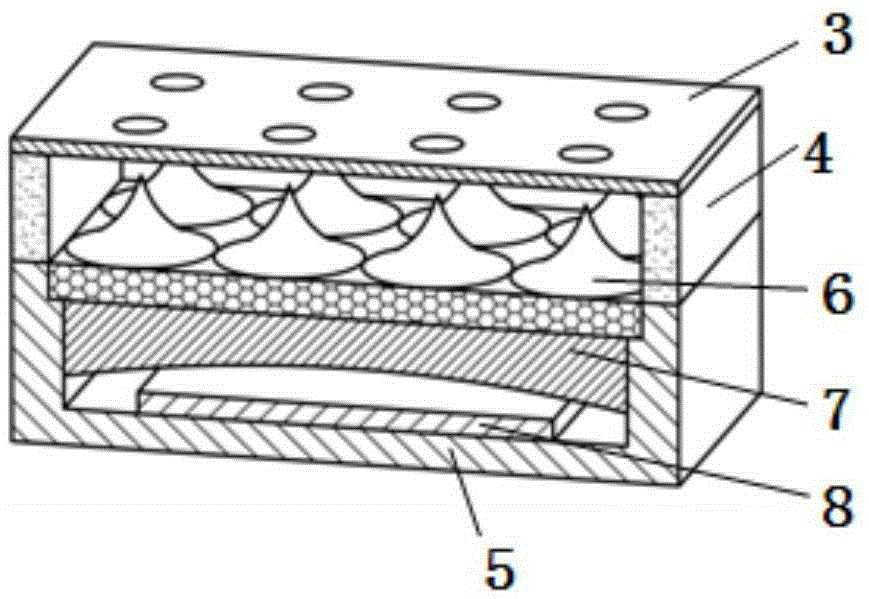

[0040] The needle-type porous material emitter array miniature field emission electric thruster of this embodiment adopts a single grid, such as figure 1 , figure 2 , image 3 shown. The gate has 16 identical gate holes in total, and the gate holes are arranged in a 4×4 manner. The bottom surface of the emitter is flat, and there are 16 emitter needles arranged on the upper surface in a 4×4 manner. The gate holes and emitter pins are distributed accordingly. When working, negative voltage is applied to the grid, positive voltage is applied to the emitter array, and all emitters work at the same time. The neutralizer emits electrons to neutralize the beam. The thruster has a square shape and a small envelope size, which is convenient for installation on tiny satellites.

Embodiment 2

[0042] 16 pins, 4 gates

[0043] The needle type porous material emitter array miniature field emission electric thruster of this embodiment adopts 4 grids. The bottom surface of the emitter is flat, and there are 16 emitter needles arranged on the upper surface in a 4×4 manner. The 4 grids are located in the same plane, and each grid has 4 grid holes arranged in a line, corresponding to 4 emission pins. When working, it is necessary to apply a negative voltage to the working gate, and a positive voltage to the emitter array. When a certain voltage is applied to all four gates, they will work simultaneously to generate the maximum thrust. 1, 2, and 3 grids are combined in different ways and work when a certain voltage is applied to produce thrusts of different sizes and action axes. like Figure 5 shown.

Embodiment 3

[0045] Emitter bottom surface is concave shape

[0046] In the needle-type porous material emitter array miniature field emission electric thruster of this embodiment, the propellant is indium, and the bottom surface of the emitter array is a concave shape ( Image 6 ), to increase the contact surface with the propellant, better store, absorb and transport the propellant. The emitter absorbs the propellant through the surface of the porous material and the tiny gap, and the propellant is transported to the tip of the firing needle through the tiny gap and the surface of the porous material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com