Single winding hybrid excitation magnetic lead screw

A hybrid excitation and magnetic screw technology, applied in the direction of permanent magnet clutch/brake, can solve the problems of low utilization rate of excitation winding, low thrust density, complex structure, etc., and achieve simple and compact, high thrust density, simple system structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

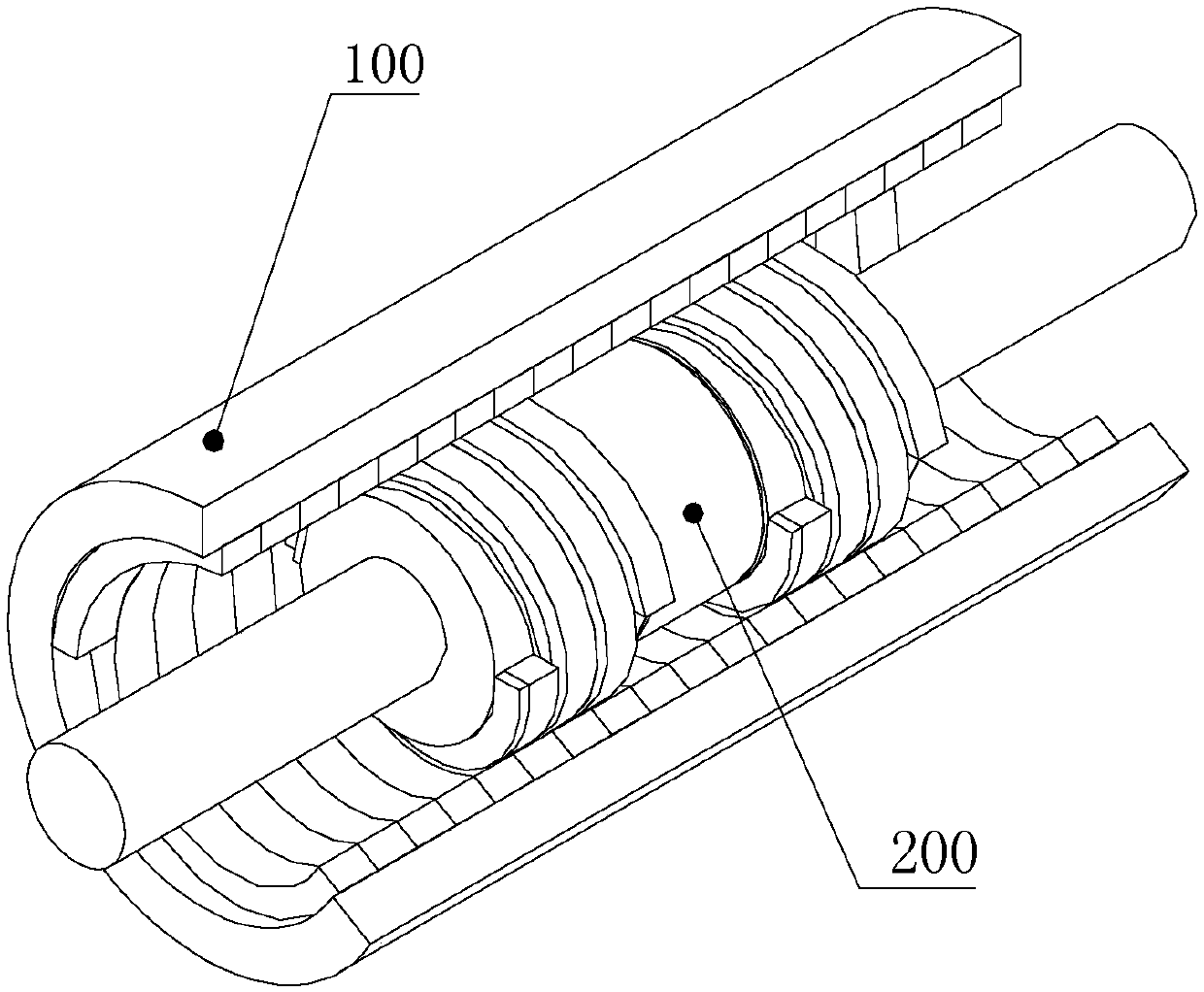

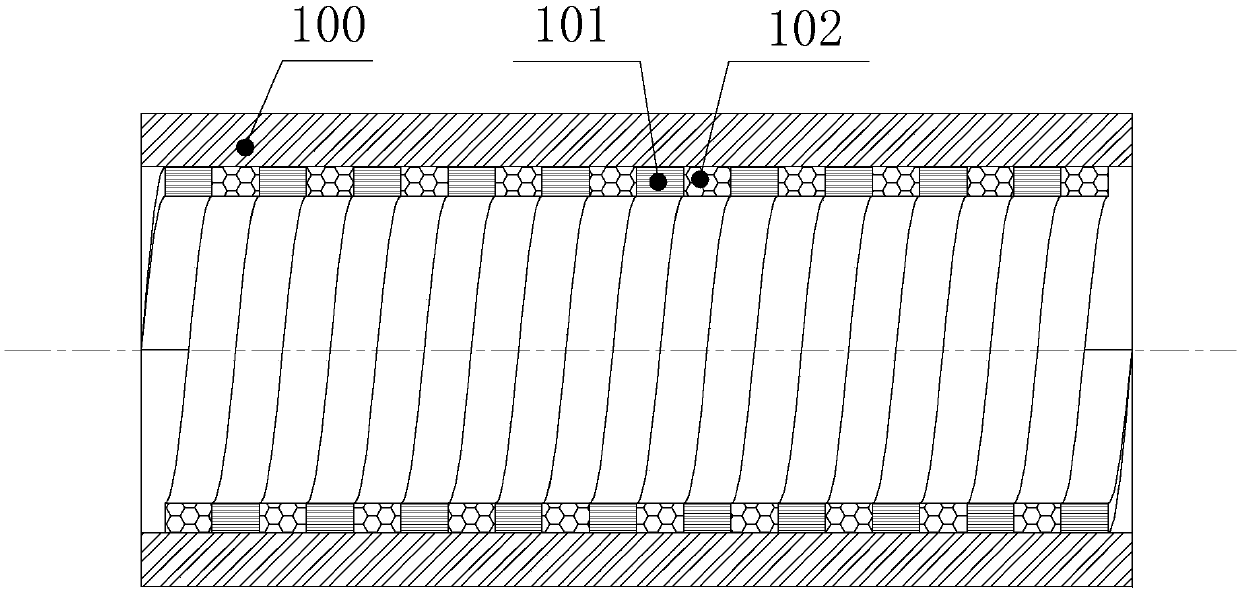

[0068] Specific implementation mode one: combine Figure 1 to Figure 5 This embodiment is described. In the single-winding hybrid excitation magnetic force lead screw described in this embodiment,

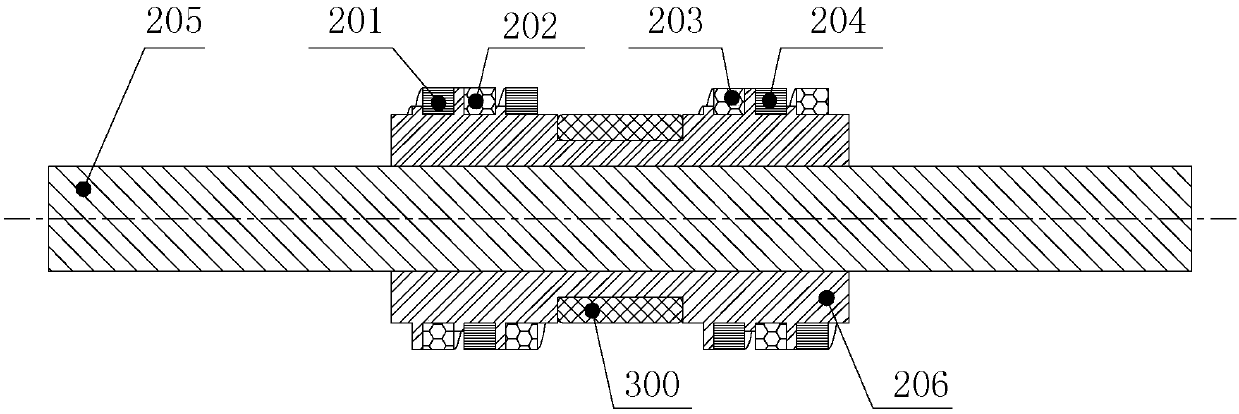

[0069] The magnetic screw 200 includes a first screw helical permanent magnet 201, a second screw helical permanent magnet 202, a third screw helical permanent magnet 203, a fourth screw helical permanent magnet 204, a first main shaft 205 and a first screw electrical iron ring 206 ;

[0070] The first screw electrical iron ring 206 is set on the first main shaft 205 and is fixedly connected with the first main shaft 205. The side wall of the first screw electrical iron ring 206 is provided with a circle of circumferential grooves 207, and the circumferential grooves 207 are used to place the annular excitation winding 300;

[0071] A helical groove 208 is formed on the sidewall of the first screw electrical iron ring 206 on the left and right sides of the circumferential groove ...

specific Embodiment approach 2

[0077] Specific implementation mode two: see Figure 1 to Figure 5 This embodiment is described. The difference between this embodiment and the single-winding hybrid excitation magnetic lead screw described in Embodiment 1 is that the polarities of the second screw helical permanent magnet 202 and the third screw helical permanent magnet 203 are opposite.

specific Embodiment approach 3

[0078] Specific implementation mode three: see Figure 1 to Figure 5 This embodiment is described. The difference between this embodiment and the single-winding hybrid excitation magnetic lead screw described in Embodiment 1 is that the heights of adjacent spiral salient poles 209 on the spiral groove 208 are different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com