Rotor punching sheet group, rotor iron core, rotor and motor

A technology of rotor punching and rotor core, which is applied in the field of rotors and motors, rotor cores, and rotor punching groups, can solve the problems that do not reflect the advantages of the tangential magnetic circuit structure, and reduce the risk of magnetic steel falling off. Save dosage, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

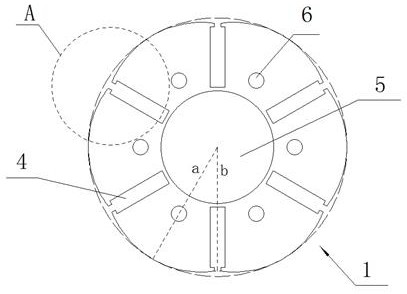

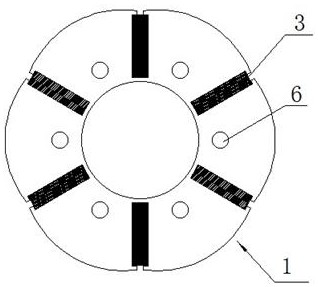

[0028] Such as Figure 1-7 As shown, a rotor punching set includes a first rotor punching 1 and a second rotor punching 2, and the centers of the first rotor punching 1 and the second rotor punching 2 both form a shaft hole 5; preferably , the inner diameter and outer diameter of the first rotor punching piece 1 and the second rotor punching piece 2 are respectively the same.

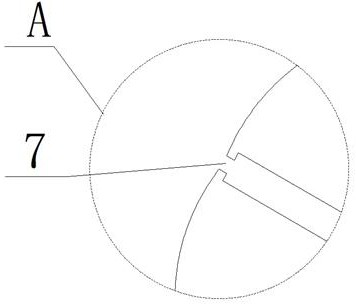

[0029] A plurality of permanent magnet slots 4 are formed on the first rotor punch 1 and the second rotor punch 2 , and the permanent magnet slots 4 extend radially along the rotor punch and are center-symmetrically distributed on the rotor punch. Such as figure 1 , 4 As shown, preferably, six permanent magnet slots 4 are respectively formed on the first rotor punching piece 1 and the second rotor punching piece 2, and the six permanent magnet slots 4 are symmetrically distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com