Quenching sensor and quenching method for shaft parts

A technology for quenching inductors and shaft parts, applied in the direction of quenching devices, furnace types, furnaces, etc., can solve the problems of reducing the reliability of threaded connections against shock and vibration, unstable quality of laser beam quenching surfaces, and uneven distribution of magnetic lines of force, etc. , to achieve the effect of reducing proximity effect, low requirements for equipment and other hardware conditions, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

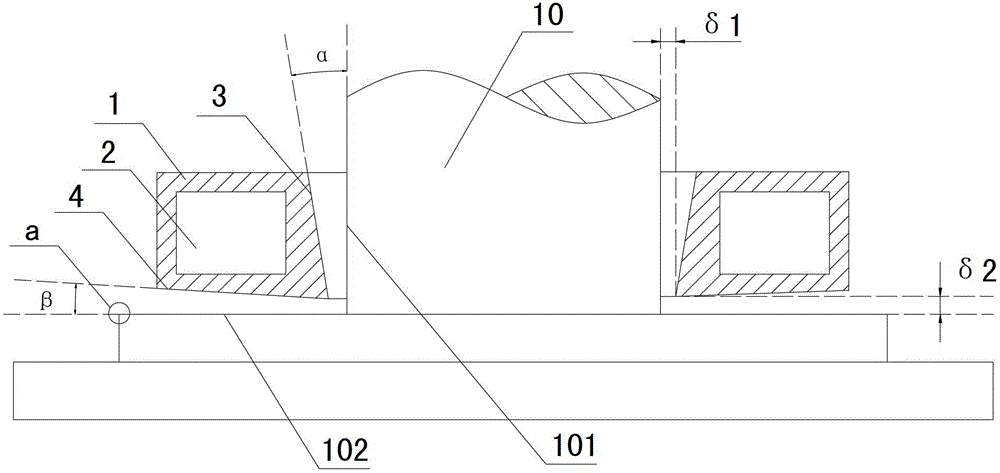

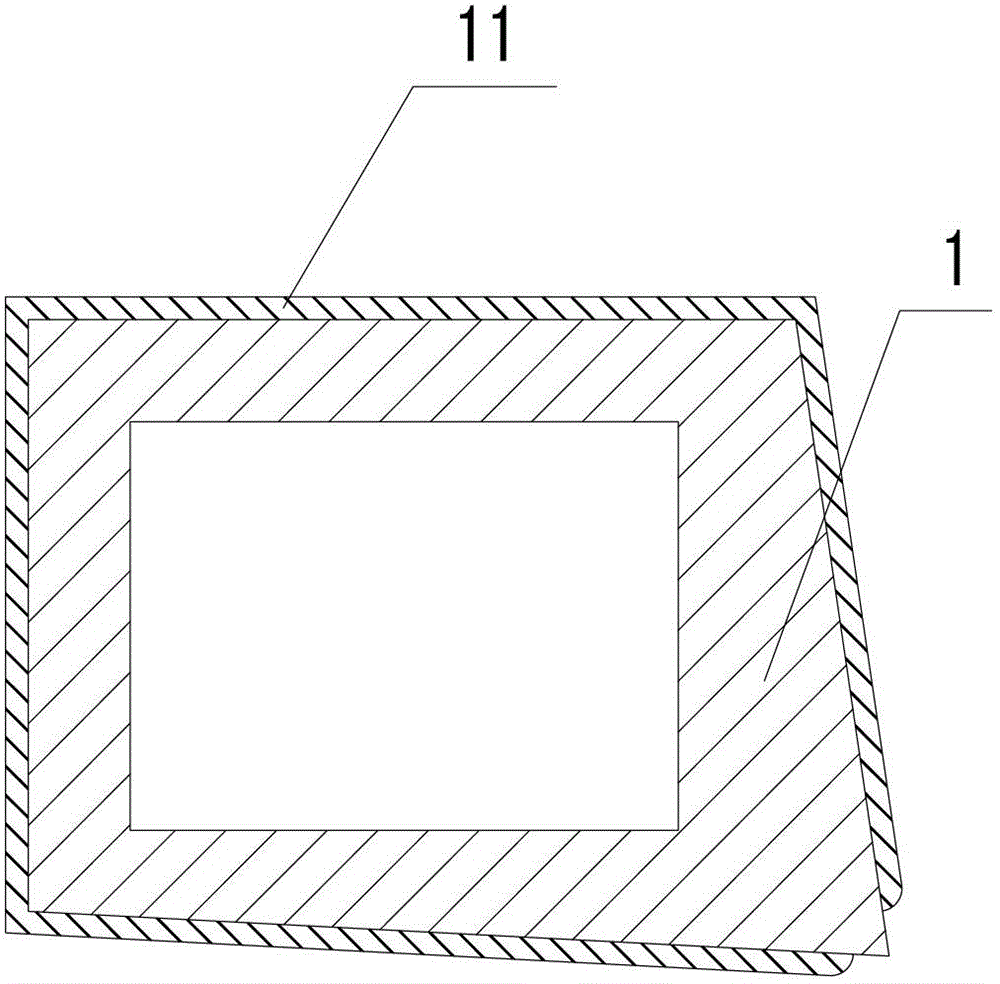

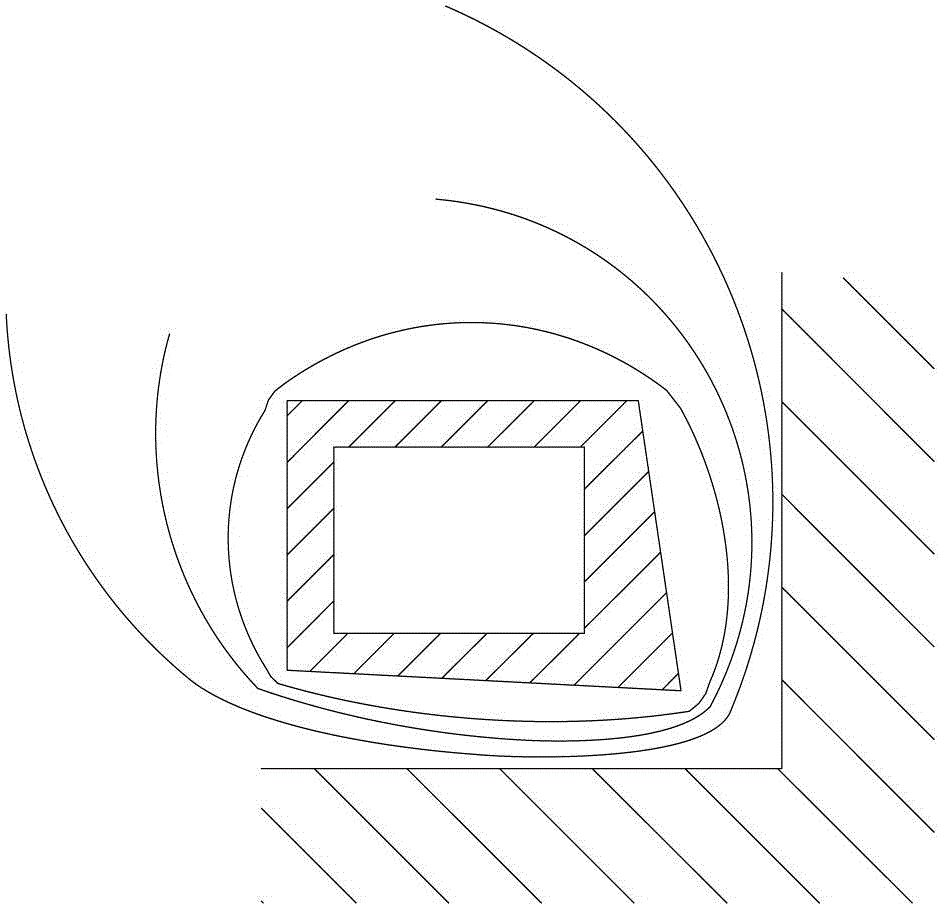

[0044] The first group of preferred embodiments: as Figure 1 to Figure 4 As shown, the quenching inductor 1 for shaft parts is an annular body, the annular inner surface 3 of the quenching inductor 1 is a tapered surface corresponding to the cylindrical surface 101 of the shaft parts to be quenched, and the annular inner surface of the quenching inductor 1 The angle between 3 and the cylindrical surface 101 of the shaft part to be quenched is α; the bottom surface 4 of the quenching inductor 1 is an inclined plane corresponding to the lower end surface 102 of the shaft part to be quenched, and the bottom surface 4 of the quenching inductor 1 and the shaft to be quenched The included angle between the lower end surfaces 102 of the parts is β.

[0045]A journal (not shown in the figure) is formed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com