Design method of a closed-loop current sensor

A technology of current sensor and design method, which is applied in the field of sensors, can solve problems such as circuit complexity and cost increase, and achieve the effects of reducing power consumption, solving magnetic flux leakage problems, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

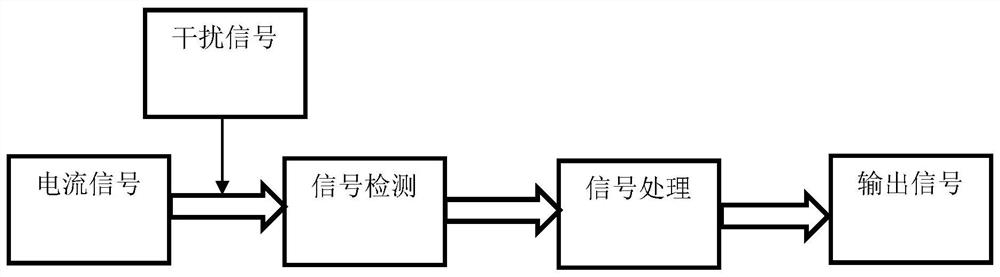

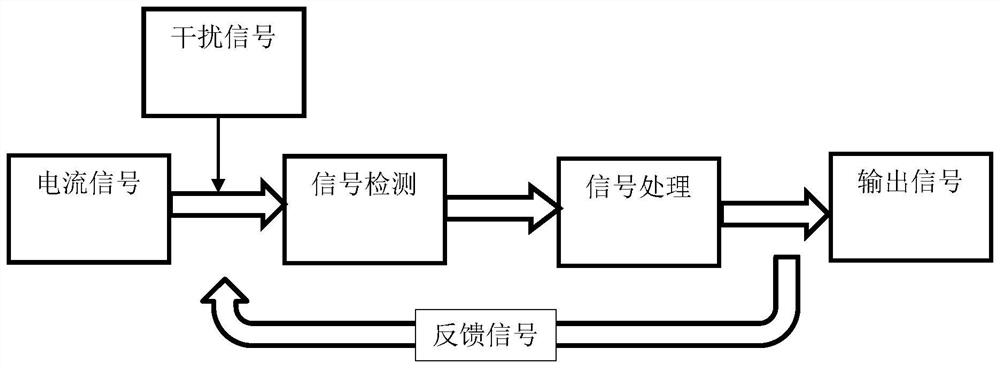

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Design a closed-loop current sensor with 100A ~ 4V output, accuracy requirement: 0.5%, power consumption requirement: 1W.

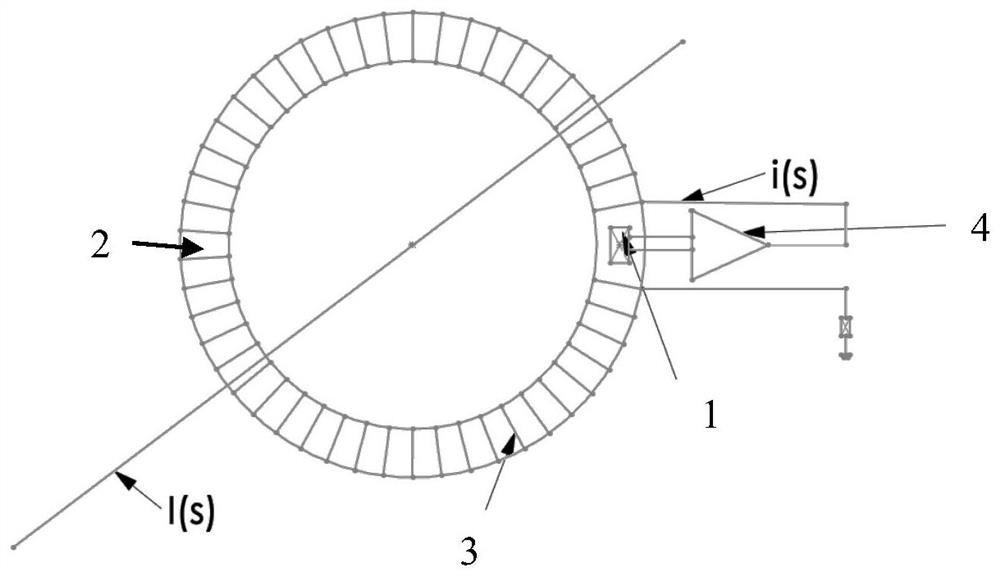

[0048] First, determine the sensor structure according to the use requirements of the sensor. The sensor adopts a skeleton shell of 35×27×4. The total number of turns of the coil is determined according to the size of the skeleton shell and the measured current. Since the outer diameter of the sensor is required to be 25mm, the The total number of turns of the coil is designed to be 1000 turns; this embodiment adopts an all-hollow magnetic circuit, that is, no iron core is arranged in the skeleton shell, and the function of the skeleton shell is to wind the feedback coil and fix the magnetic sensing chip ( Figure 4 ), the magnetic sensing chip adopts the tunnel magnetoresistance chip;

[0049] Determine the size of the secondary current according to the power consumption of the sensor. The power consumption requirement of the sensor is 1W, and the...

Embodiment 2

[0054] Design a closed-loop current sensor with 100A ~ 4V output, accuracy requirement: 0.5%, power consumption requirement: 1W.

[0055] First, determine the sensor structure according to the use requirements of the sensor. The sensor adopts a skeleton shell of 35×27×4. The total number of turns of the coil is determined according to the size of the skeleton shell and the measured current. Since the outer diameter of the sensor is required to be 25mm, the The total number of turns of the coil is designed to be 1000 turns; the iron core of this embodiment is composed of 12 iron core segments arranged at even intervals along the circumference ( Figure 5 ), the 12-section iron core segment and the magnetic sensing chip are arranged in the skeleton shell ( Figure 6 ), the magnetic sensing chip adopts the tunnel magnetoresistance chip;

[0056] Determine the size of the secondary current according to the power consumption of the sensor. The power consumption requirement of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com