Permanent-magnetic rotor with non-magnetic-permeable distance sleeve and method for manufacturing permanent-magnet rotor

A technology of permanent magnet rotor and manufacturing method, which is applied in the direction of magnetic circuit rotating parts, manufacturing stator/rotor body, magnetic circuit shape/style/structure, etc. It is too suitable for problems such as magnetic flux leakage at the axial end of the rotor, so as to reduce the magnetic leakage interference problem, improve the anti-electromagnetic interference and electromagnetic compatibility capabilities, and achieve the effect of low magnetic flux leakage at the axial end.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

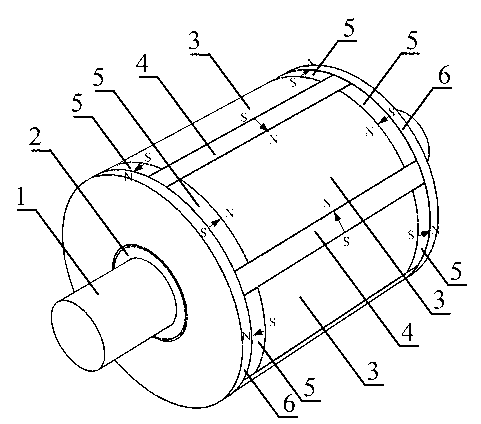

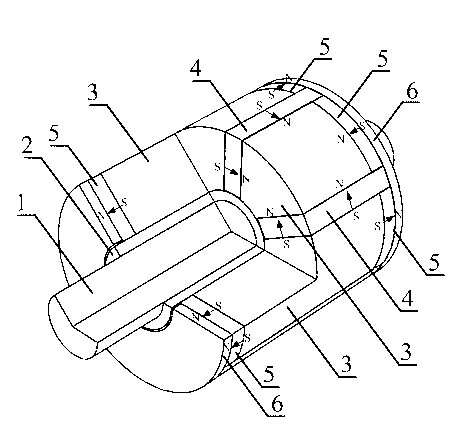

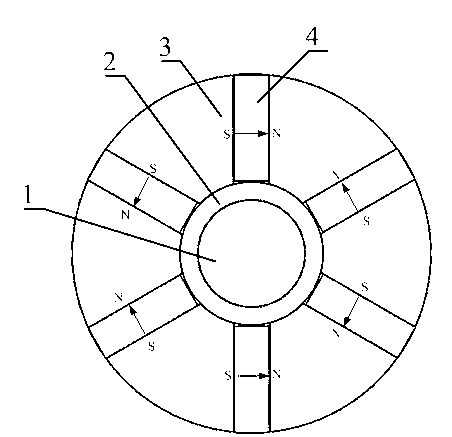

[0021] Embodiment 1 of the present invention: when making the rotor of the permanent magnet motor, adopt a kind of manufacturing method of the permanent magnet rotor that is provided with non-magnetic spacer sleeve of the present invention to make, when making, put one on the rotor shaft earlier A non-magnetic isolation sleeve made of non-magnetic material, the non-magnetic material can be made of existing aluminum, aluminum alloy, copper, copper alloy, or stainless steel; then the rotor core is made into a fan shape, and the fan-shaped rotor core Evenly distributed and fixed on the non-magnetic isolation sleeve, and at the same time, each fan-shaped rotor core installed and fixed on the non-magnetic isolation sleeve except its arc-shaped upper end surface and the contact surface with the non-magnetic isolation sleeve, the other four sides The permanent magnet blocks made of permanent magnet materials are used to fit and surround them, and the magnetic poles of each permanent m...

Embodiment 2

[0023] Embodiment 2: When making the permanent magnet rotor provided with the non-magnetic spacer sleeve of the present invention, it can be made according to the method of Embodiment 1. When making, the two adjacent second permanent magnet blocks 5 can also be The two sides bear against each other, and the two ends of the first permanent magnet 4 are respectively pushed against the inner end faces of the second permanent magnet 5 at both ends (such as Figure 6 shown); the rest of the production methods are the same as in Example 1.

Embodiment 3

[0024] Embodiment 3: when making the permanent magnet rotor provided with the non-magnetic spacer sleeve of the present invention, it can be made according to the method of embodiment 1. When making, the two adjacent second permanent magnets 5 can also be There is a gap between the two sides, so that the two ends of the first permanent magnet 4 are respectively facing the gap positions of the two second permanent magnets 5 adjacent to the two ends (such as Figure 7 shown); the rest of the production methods are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com