Double-stator rotor-yoke-free oriented silicon steel sheet permanent magnet linear motor

A technology of permanent magnet linear motor and oriented silicon steel, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems that have not been progressed, and achieve the suppression of tooth tip magnetic flux leakage, suppression of magnetic circuit asymmetry, and improvement of air gap The effect of magnetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

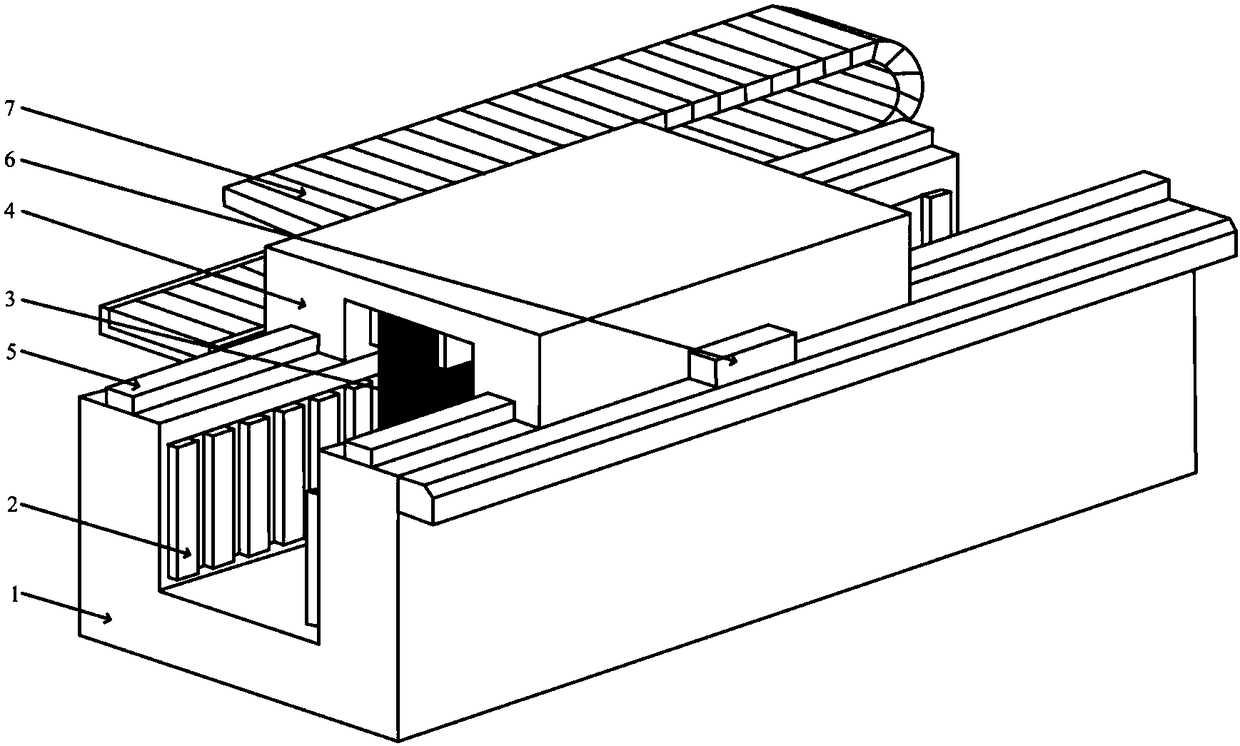

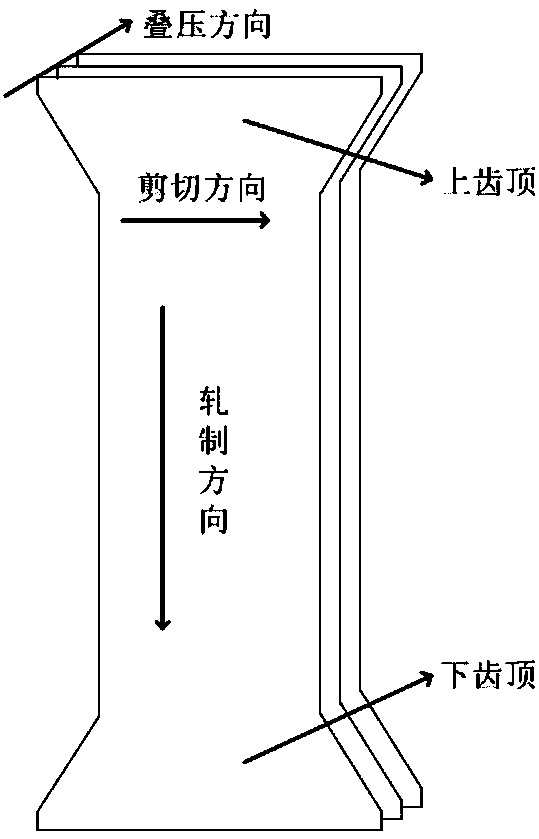

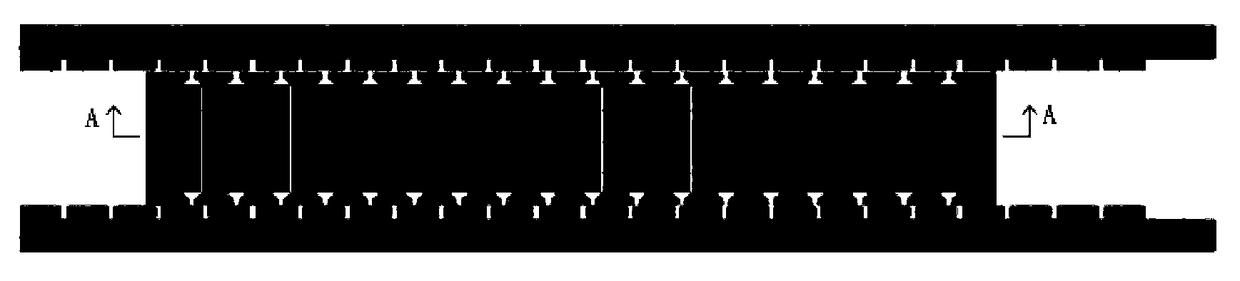

[0031] The invention provides an overall structure of a permanent magnet linear motor with oriented silicon steel sheet with dual stators and no mover yoke. figure 1 As shown, a U-shaped double stator 1 is formed by using a double stator and a bottom plate. Two rows of permanent magnets 2 are installed on both sides of the inner wall of the U-shaped double stator 1, and two guide rails 5 are installed on the top. The permanent magnets on both sides are arranged correspondingly and magnetized in different directions, and the same row of permanent magnets and adjacent permanent magnets are also magnetized in different directions. The mover bearing plate 4 is in an inverted U shape, and there is a groove on the left and right sides. The groove passes through the guide rail 5 on the stator to form a sliding connection between the mover bearing plate 4 and the U-shaped stator 1. A position sensor 6 is installed on one side of the outer wall of the mover weighing plate 4 to improve th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com