Segmented iron core IPM plastic package forming rotor

A block type, injection molding technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, electrical components, etc., can solve the problems of reducing the utilization rate of rotor magnetic tiles, large magnetic flux leakage, etc., and achieve dimensional stability. Good, high pressure, high structural stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

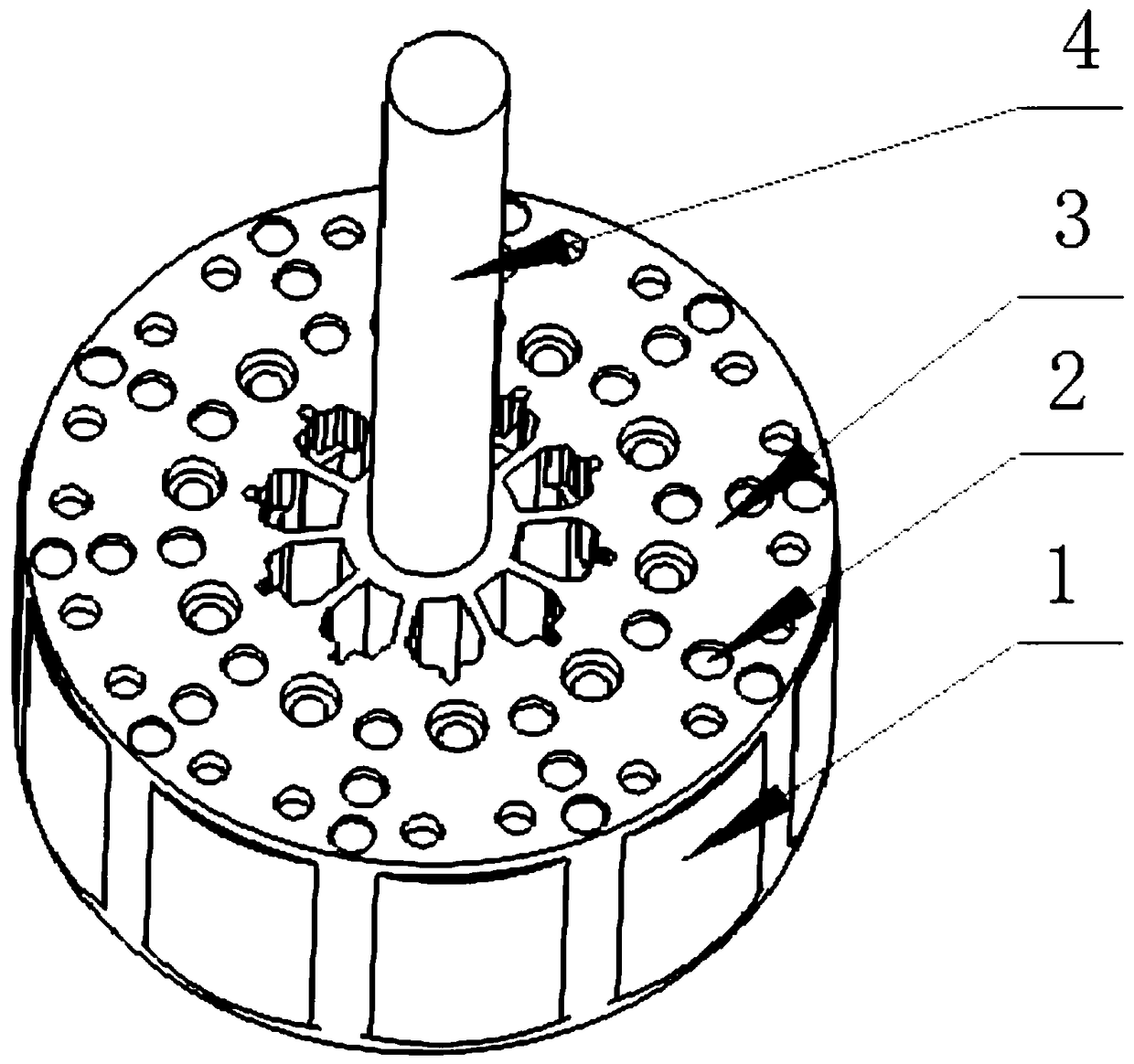

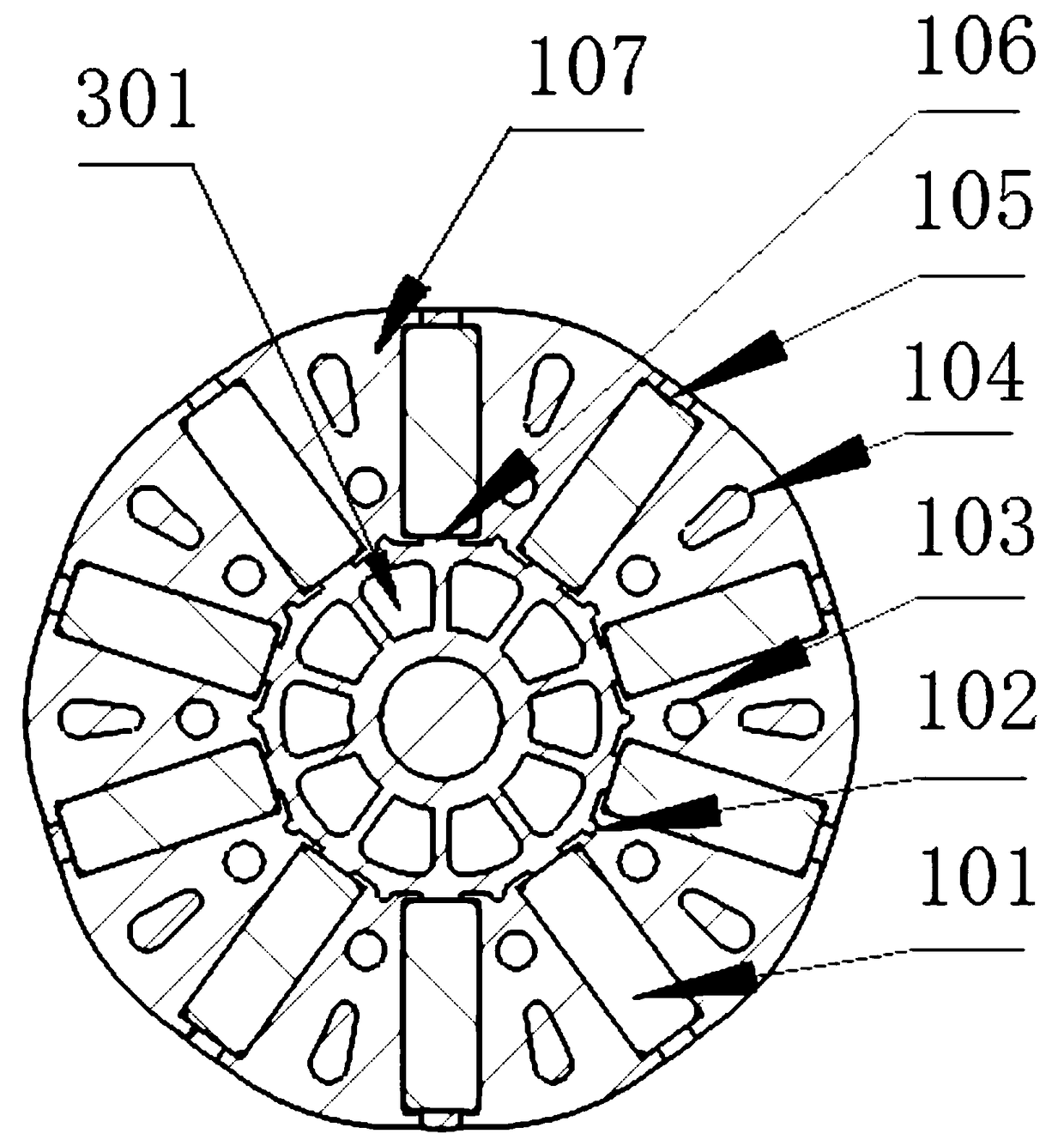

[0029] Such as Figure 1-2 As shown, a block-type core IPM plastic molded rotor includes a rotor core 1, a magnetic tile 2, a PBT3 and a shaft 4, and the rotor core 1 is composed of a plurality of identical core blocks 107, each two Adjacent iron core blocks 107 are provided with magnetic tile grooves 101 and anti-flux leakage grooves for reducing magnetic flux leakage. phase separation, each iron core block 107 is provided with a positioning structure for positioning the iron core block 107, the magnetic tile 2 is inserted into the magnetic tile groove 101, and the magnetic tile 2 is fixed on the rotor core 1 through PBT3 , the shaft 4 is connected as a whole with the magnetic tile 2 and the rotor core 1 through the PBT3.

[0030] In order to realize process positioning, the positioning structure includes positioning grooves 102 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com