Detection device of inner hole coaxiality of large disc type workpiece

A detection device and coaxiality technology, applied in measuring devices, mechanical measuring devices, mechanical devices, etc., can solve problems such as difficulty in detecting the coaxiality of the inner hole of large disc workpieces, and meet the requirements of low detection technical conditions, Easy operation and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

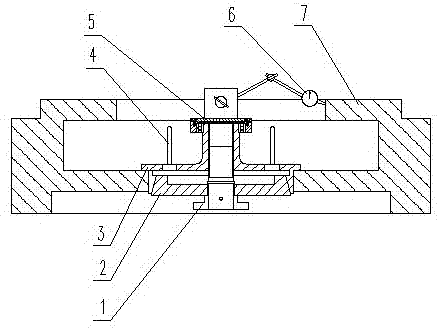

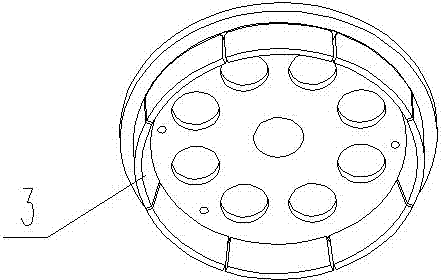

[0012] figure 1 It is a structural schematic diagram of the present invention, including a handwheel 1, an inner cone 2, an outer cone 3, a handle 4, a rotary table 5 and a dial indicator 6, and the inner cone 2 is assembled in the inner cone hole of the outer cone 3 , the outer cone 3 is made of spring steel and has eight grooves on the side, so when the inner cone hole is stressed, it has the function of expanding outward. The top of the outer cone 3 is provided with a rotary table 5 with bearings. A dial gauge is provided, the handwheel 1 is connected to the inner cone 2 and the outer cone 3, and the outer cone 3 is also provided with a handle 4.

[0013] In actual operation, two hands hold the handle 4 and place the detection device as a whole into the inner hole of the workpiece 7, then rotate the hand wheel 1 to force the inner cone 2 to move inward axially, and at the same time, the outer cone is The outer circle of the cone 3 expands, thereby eliminating the gap betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com