Drilling fixture for crank positioning pin hole

A technology for positioning pin holes and drilling fixtures, which is used in positioning devices, drilling/drilling equipment, clamping and other directions, can solve the problems of inability to accurately position and process, and it is difficult to meet the drilling accuracy of crank positioning pin holes. The effect of convenient machining, high positioning accuracy, and easy loading and unloading operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below according to accompanying drawing.

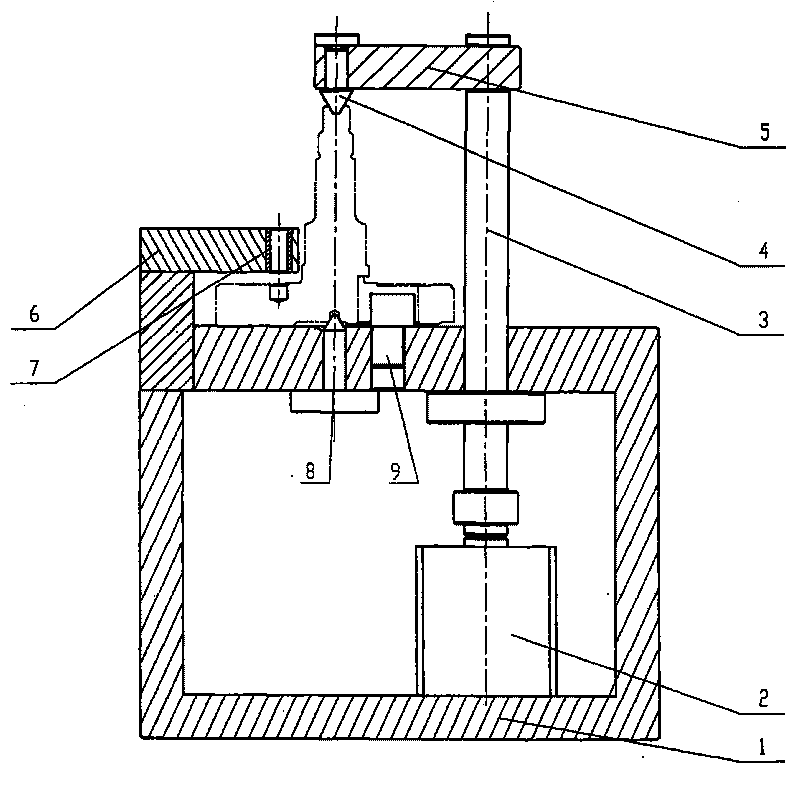

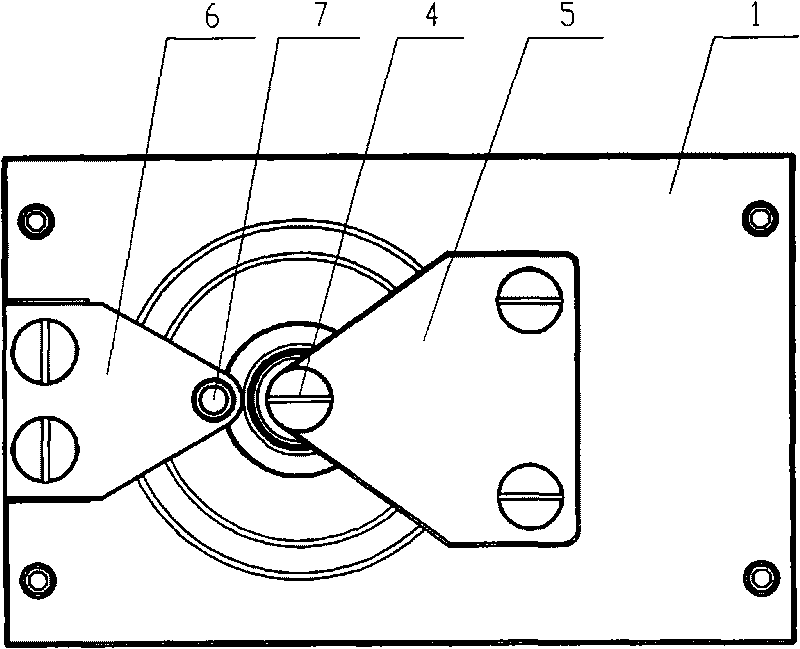

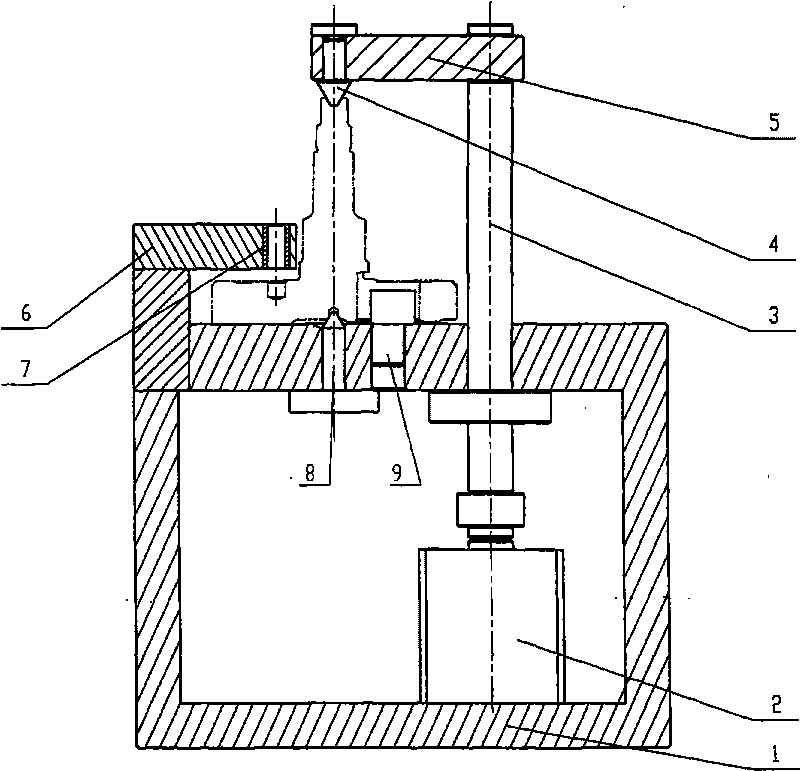

[0014] The crank locating pin hole drilling jig shown in the accompanying drawings comprises a clamp body 1, a cylinder 2, a column 3, an upper top 4, a positioning plate 5, a template 6, a drill sleeve 7, a floating top 8 and a positioning pin 9. In the present invention, the clamp body 1 is a frame-shaped main body member. The cylinder 2 is installed in the inner cavity of the clamp body 1. The top surface is provided with an upward floating top 8 and a positioning pin 9. The left side wall is higher than the top surface and faces the right horizontal connection template 6. The right end of the template 6 is provided with a vertical drill sleeve 7 . The cylinder 2 connected to the column 3 in the inner cavity of the clamp body 1 passes through the top face of the clamp body 1, the top of the column 3 is connected to the right end of the positioning plate 5, and the left end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com