Fixture for gear shaping on thin-wall outer gear ring

A gear ring and thin-walled technology, which is applied in the field of thin-walled outer gear ring gear shaping fixtures, can solve the problems that the gear ring is difficult to meet the matching requirements of high-end cars, and the positioning accuracy of the expansion mandrel fixture cannot be very high, so as to achieve small deformation, Reasonable axial locking structure and simple positioning structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

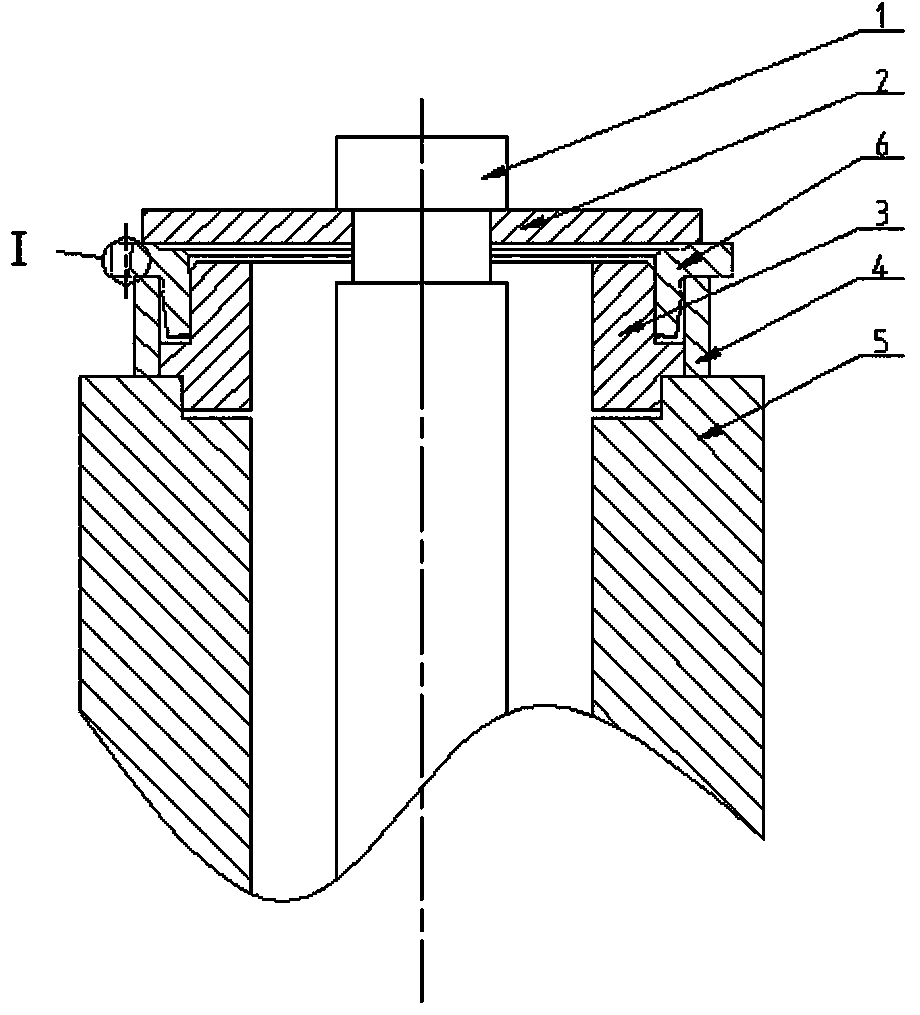

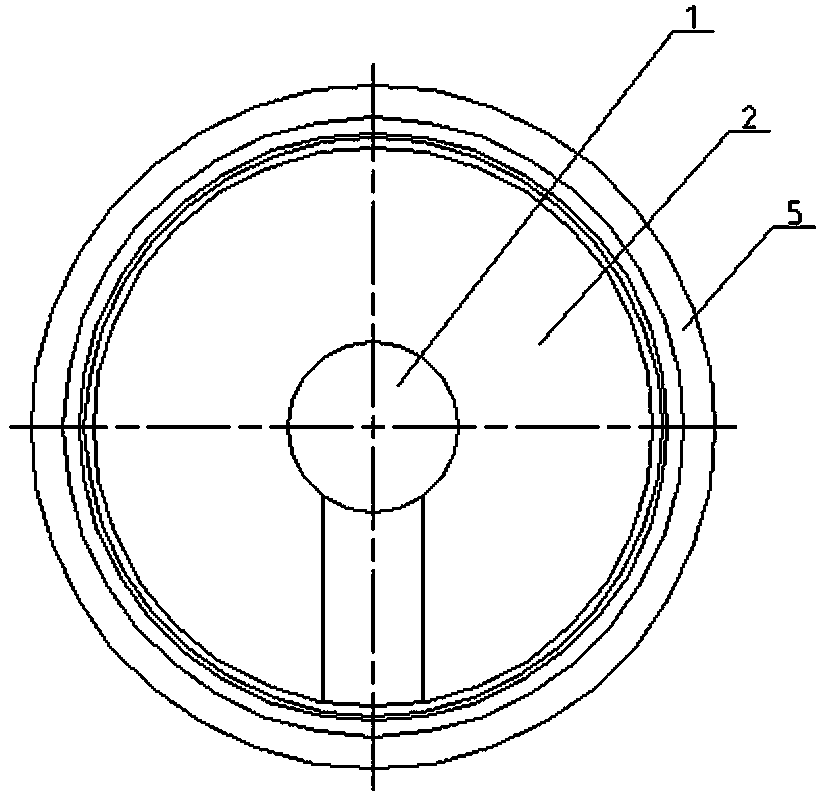

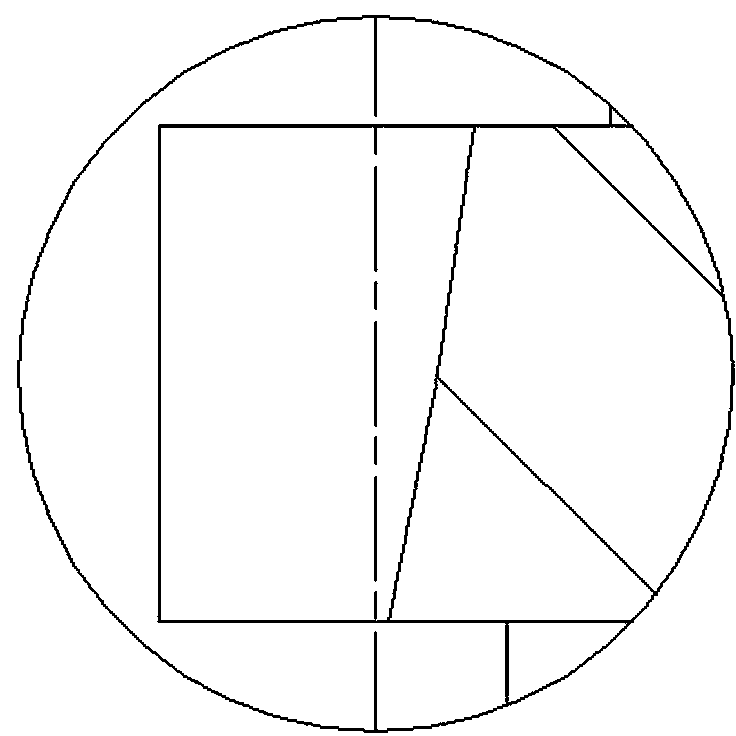

[0014] figure 1 The shown thin-walled external gear ring gear shaping fixture is composed of a tie rod 1, a washer 2, a shaft seat 3, a shaft sleeve 4 and a base 5, and the fixture is positioned and installed on the gear shaping machine table. The base 5 is the main component of the clamp and is used to carry other supporting components. The upright base 5 is a hollow shaft segment, and the upward end face is provided with a concave stop, which is used for positioning and installing the shaft seat 3 . The shaft seat 3 is a multi-section shaft member. The two shaft segments on the upper and lower sides of the outer convex shoulder are coaxial. 5 spins. The shaft segment located in the previous section is used for the positioning of the workpiece 6 , and its outer diameter is matched with the inner hole of the workpiece 6 in a clearanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com