Multi-stage centrifugal pump with low pressure pulsation

A low-pressure, centrifugal pump technology, applied to radial flow pumps, components of pumping devices for elastic fluids, pumps, etc., can solve the problems of reduced reliability and life of centrifugal pumps, affecting pump shaft rotation, and pump shaft disturbances and other issues to achieve the effect of improving reliability and service life, reducing water flow rate, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

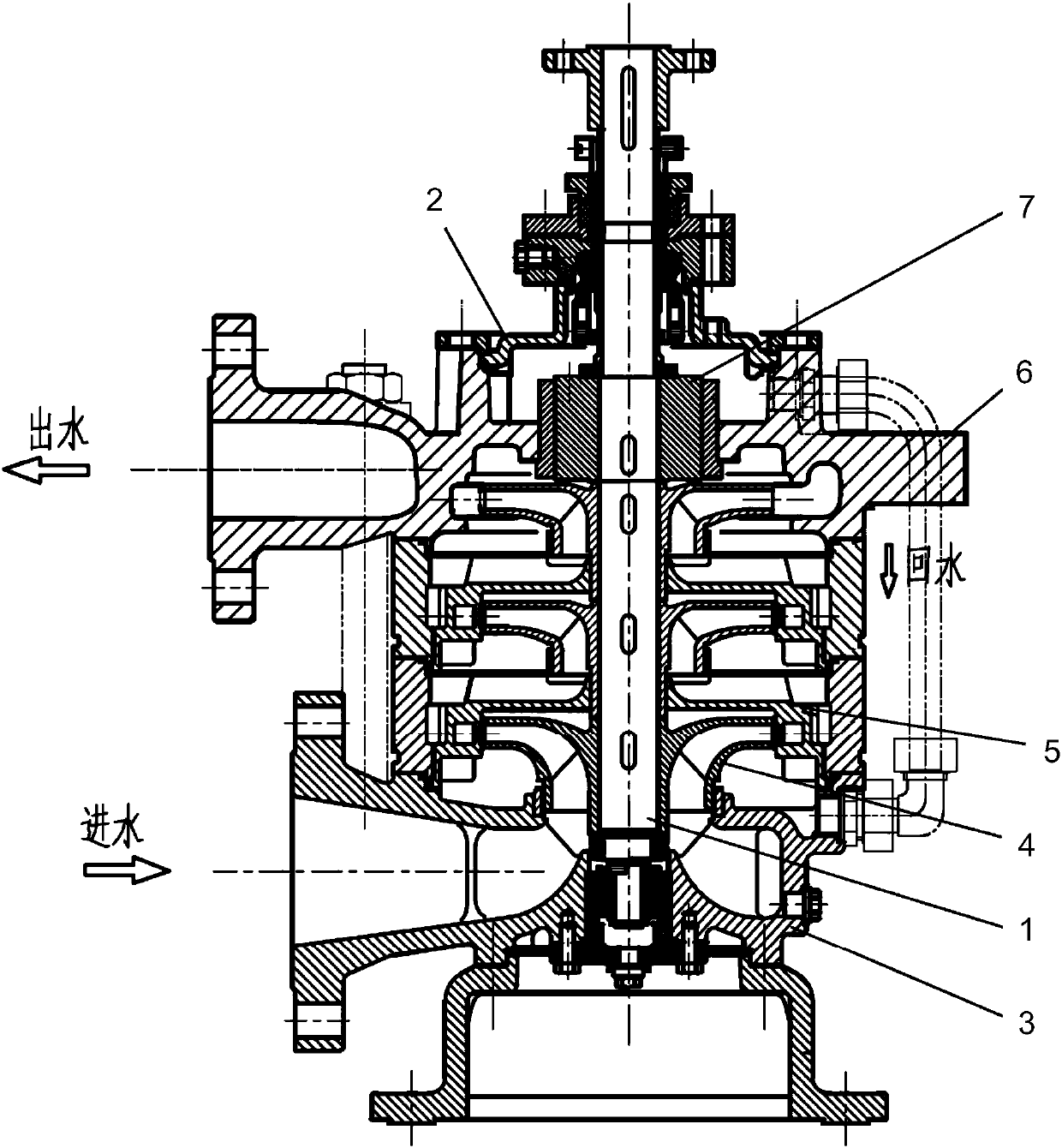

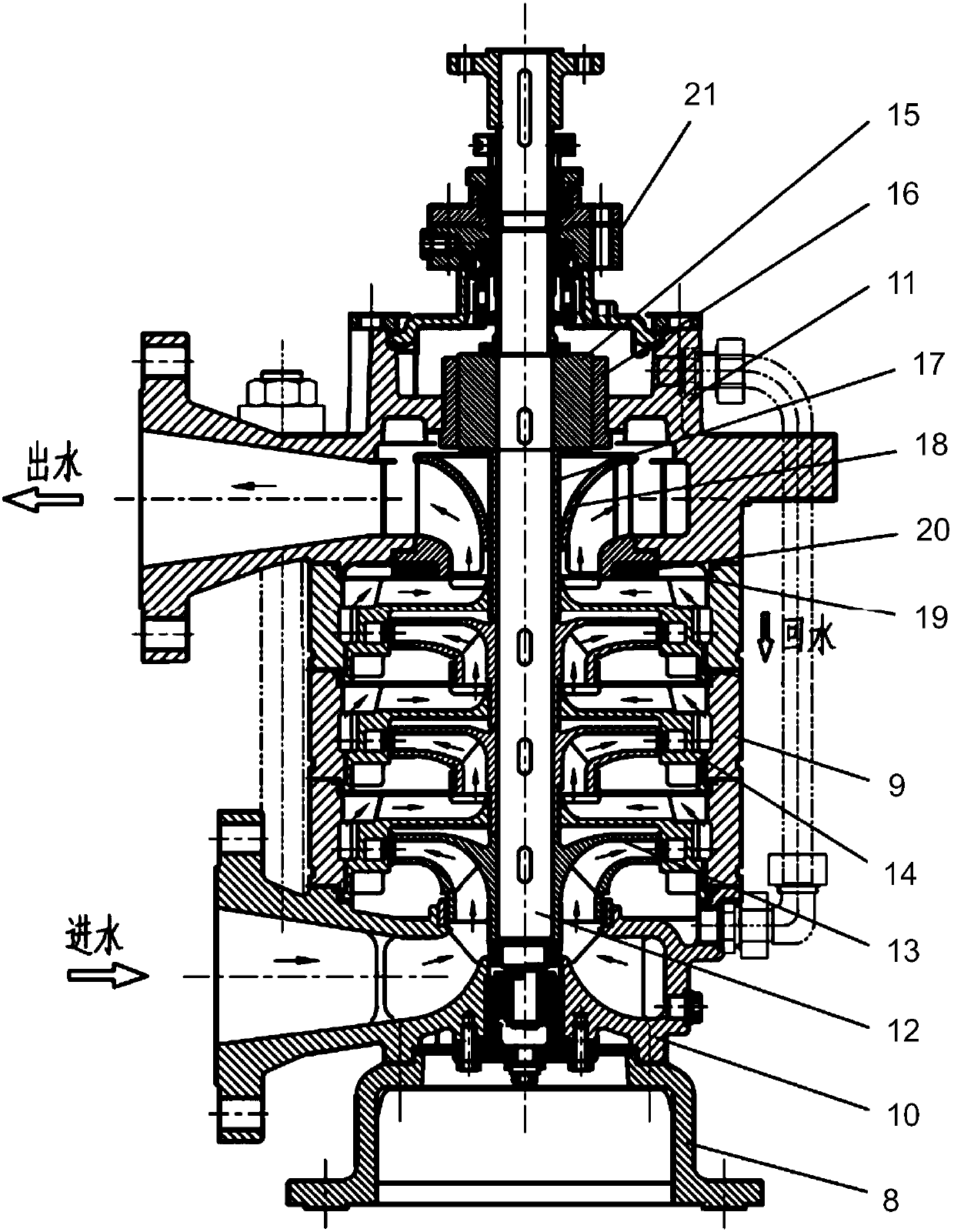

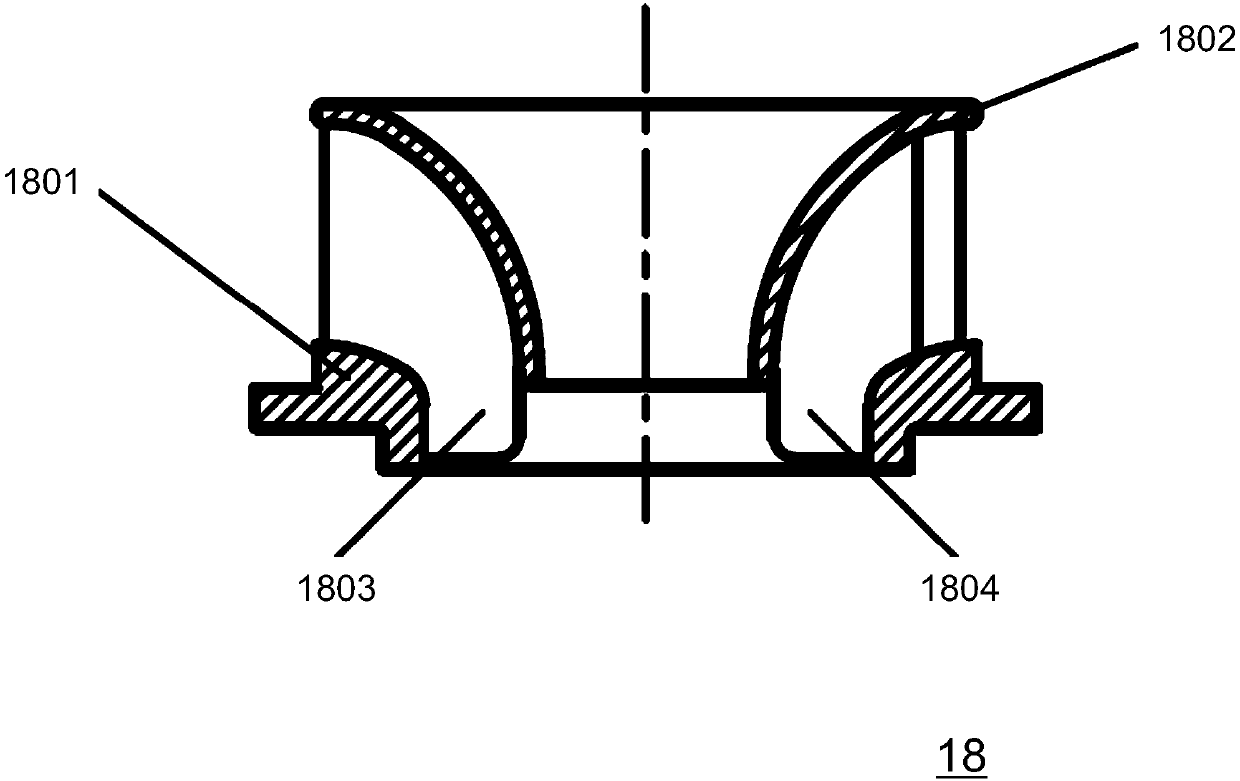

[0025] Please combine Figure 2 to Figure 5 As shown, a low-pressure pulsation multistage centrifugal pump provided by the present invention, the present embodiment adopts a multistage centrifugal pump of vertical structure, including a base 8, a pump body 9 installed on the base 8, and the pump body 9 The lower end is provided with a suction section 10, the upper end of the pump body 9 is provided with an extruding section 11, and a pump shaft 12 located inside the pump body 9 is fixedly connected with a plurality of impellers 13 and guide vanes 14 combinations, and The combination of the suction section 10, multiple impellers 13, guide vanes 14 and the extrusion section 11 form the inner cavity flow channel of the pump body 9, the upper end of the pump shaft 12 is provided with a balance drum 15, and the outer side of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com