Sink roll with throughflow holes

A technology of sunk rollers and through-flow holes, applied in coating, metal material coating process, hot-dip plating process, etc., can solve the problems of inability to circulate zinc liquid, poor structural strength, and rigidity, and achieve improved strength and rigidity. The effect of improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

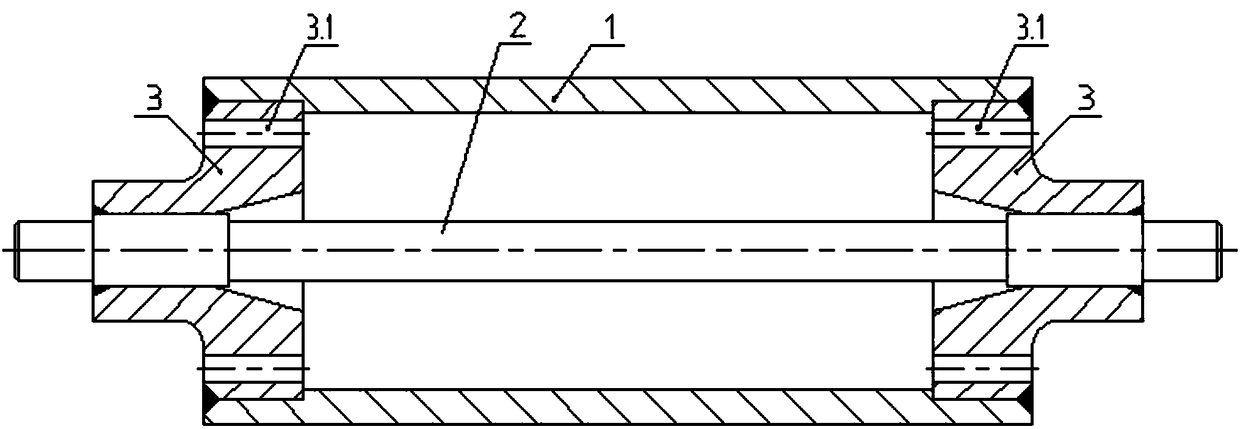

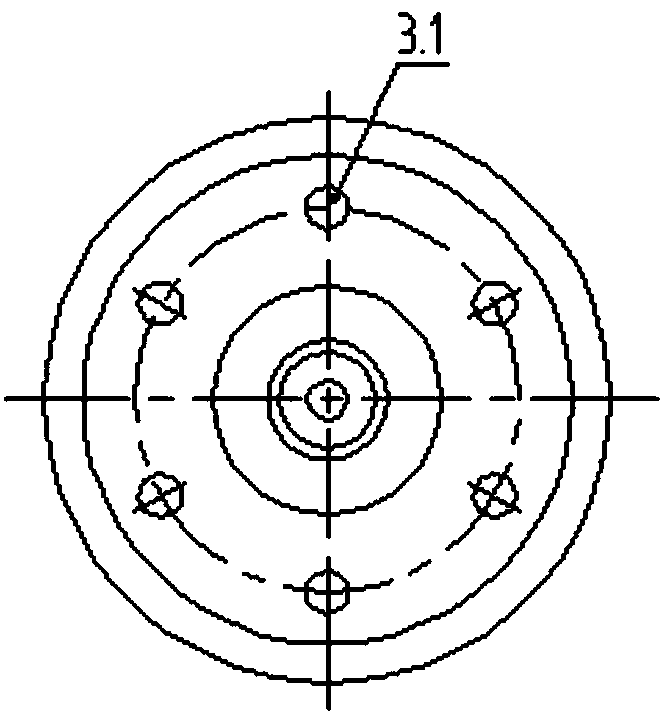

[0014] The sinking roller with flow holes shown in the accompanying drawings includes a roller 1, a roller shaft 2, and two connecting bushes 3; the connecting bushing 3 is a stepped structure, and the big end is a flange; the roller 1 has two The spigot hole at the end is set on the flange of the connecting sleeve 3 and is fixedly connected; the roller shaft 2 is an integral structure that axially penetrates the inner holes of the two connecting sleeves 3 and is fixedly connected with the two connecting sleeves; the connecting shaft A number of (six in this embodiment) circumferentially arranged axial through holes 3.1 that communicate with the inner cavity of the roller 1 are evenly distributed on the flange of the sleeve 3 .

[0015] Grooves are respectively provided at the outer ends of joints of the joints of the outer circumferenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com