Pipe segment splicing method for segmental prefabricated underground pipe gallery

A technology for segment assembly and underground pipe gallery, which is applied in underground chambers, shaft equipment, earthwork drilling and mining, etc., can solve the problem of not being able to immediately realize the shear force transmission of segment joints sealed by water-stop strips between segments, and the lack of soil The extrusion effect of the body, the inability to complete the extrusion and self-locking process of the segment, etc., achieve the effect of reducing the construction cost of the pipe gallery, increasing the promotion value, and reducing the difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

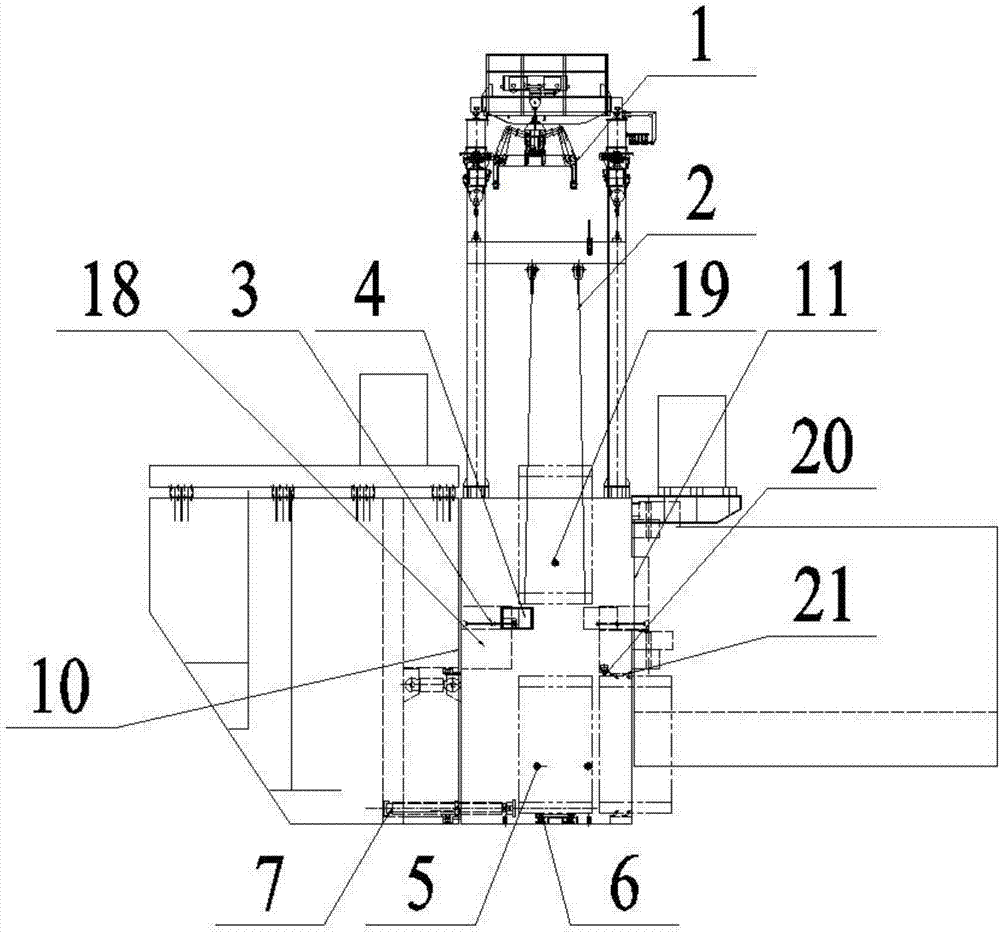

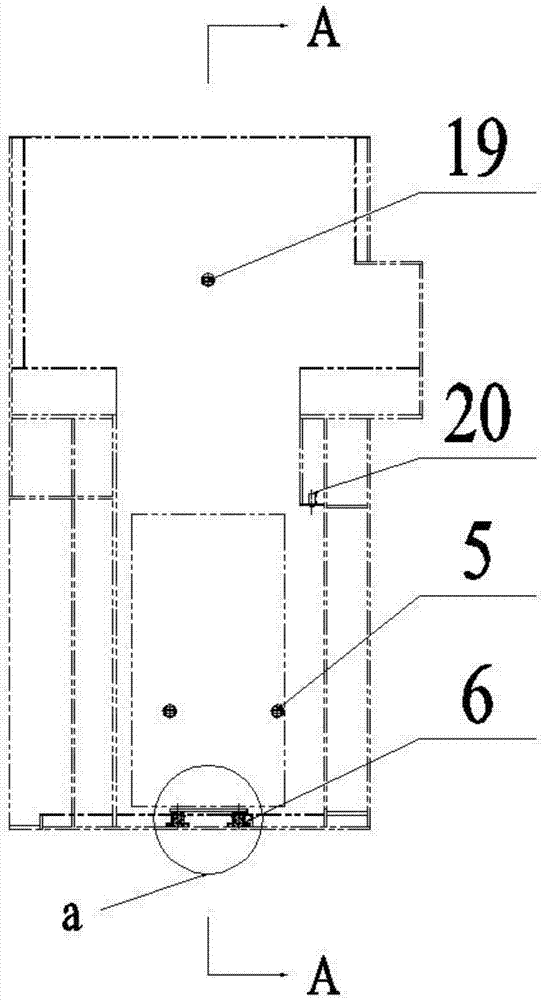

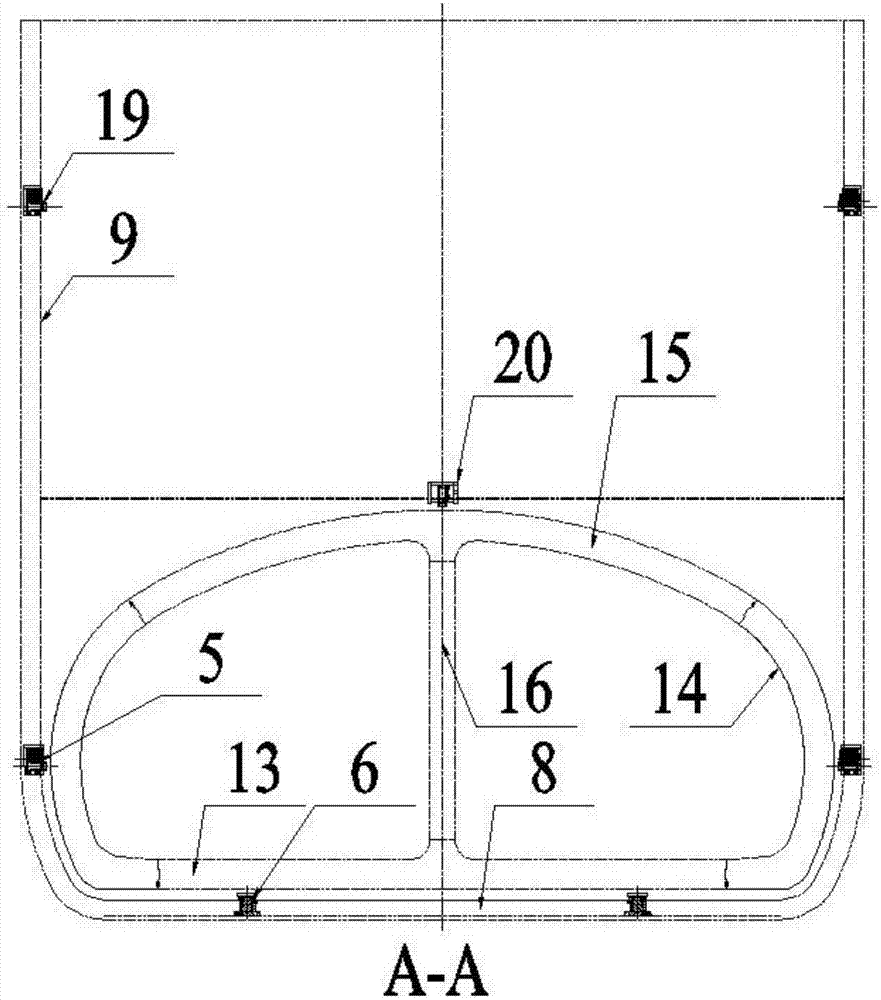

[0031] Such as Figure 1~5 As shown, it is a schematic structural view of the segment assembly equipment of this embodiment, including a bottom plate 8 laid in the installation groove of the pipe gallery, and the horizontal direction of the bottom plate 8 (the transverse direction of this embodiment refers to the width direction of the pipe gallery, and the longitudinal direction refers to the width direction of the pipe gallery). length direction) two side plates 9 are arranged on both sides, and the side plates 9 are fixed on the bottom plate 8 to form a segment assembly cabin. The plate 11 is provided with a guide ring for the segments to pass through. After the segment parts are assembled in the segment assembly cabin, they are pushed into place by the push cylinder 7 in the segment assembly cabin, and are connected with an adjac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com