Offshore oil pipe joint outer wall drilling fixture

A technology of conduit joints and offshore oil, which is applied in the direction of drilling templates for workpieces, etc., can solve problems such as poor drilling quality, low production efficiency, and failure to meet mass production requirements, and achieve high production efficiency and stable drilling quality , The effect of fast loading and unloading of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

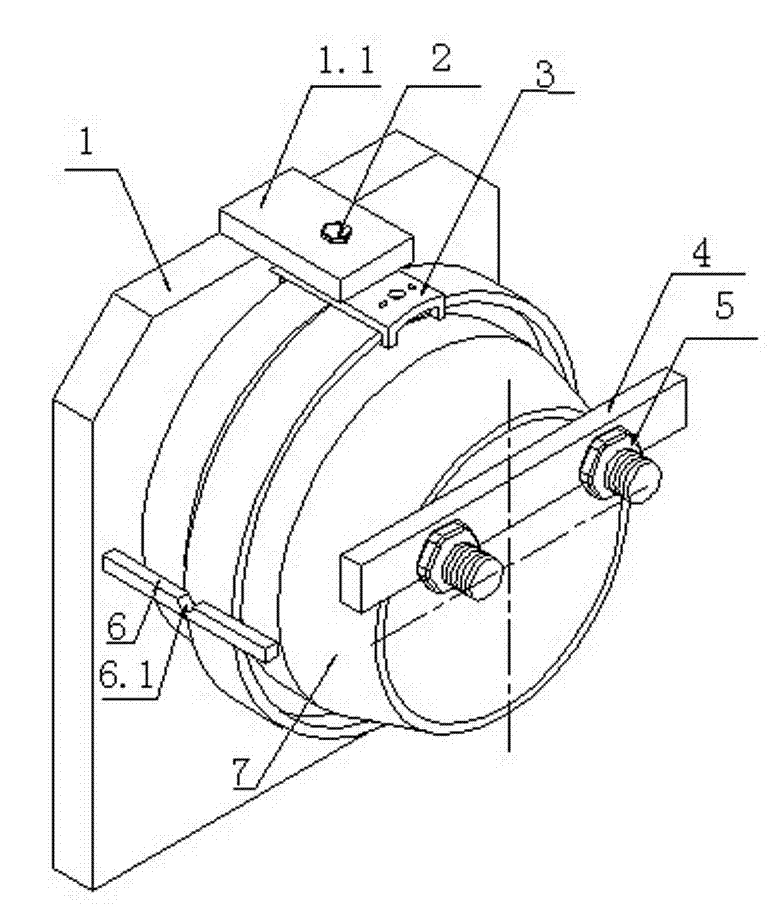

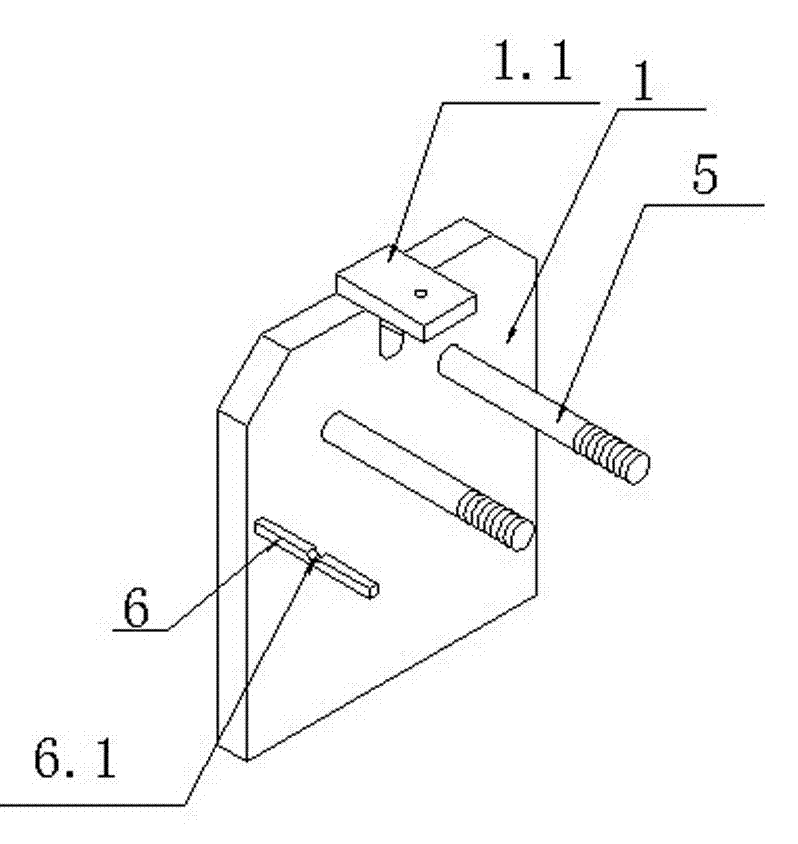

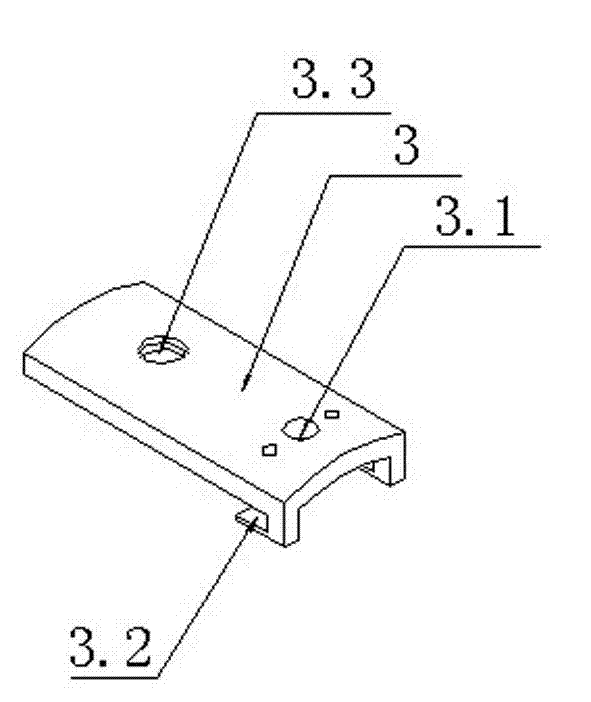

[0017] figure 1 The shown drilling jig for the outer wall of the offshore oil conduit joint includes a jig body 1 , bolts 2 , a drilling mold 3 , a pressing plate 4 , a screw assembly 5 and a limit rod 6 . The clamp body 1 is an upright flat plate member, which is attached to the workbench of the drilling machine during installation, and an outwardly extending connecting plate 1.1 perpendicular to the work surface and parallel to the axis is provided in the middle of the top surface. The pressing plate 4 and the screw assembly 5 form a two-bar positioning support and locking mechanism. Described jig 3 is arc-shaped and long, and the radius of curvature of the inner arc is equal to the radius of the outer wall of the workpiece. One end is provided with screw hole 3.3 for connection, and the other end is provided with jig hole 3.1 and li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com