Laser marking method for plastic bottle caps

A laser marking and laser marking technology, used in laser welding equipment, welding equipment, metal processing and other directions, can solve the problems of loose connection and tightness not reaching the best state, and achieve the effect of simple positioning structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

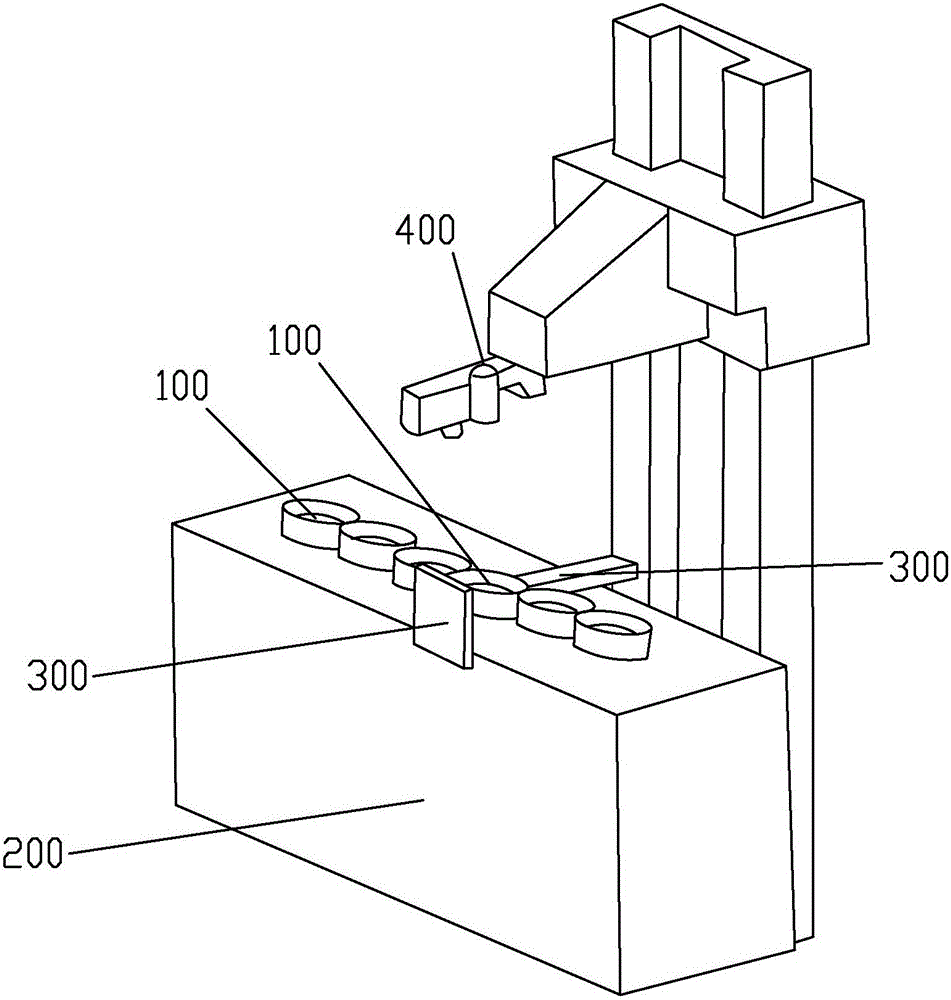

[0026] Such as Figure 1 to Figure 3 Shown, a method for laser marking plastic bottle caps, comprising the following steps:

[0027] (1): Place the plastic bottle cap 100 on the production line and transfer it to the laser marking platform 200 via the conveying device. Cover 100 positioning;

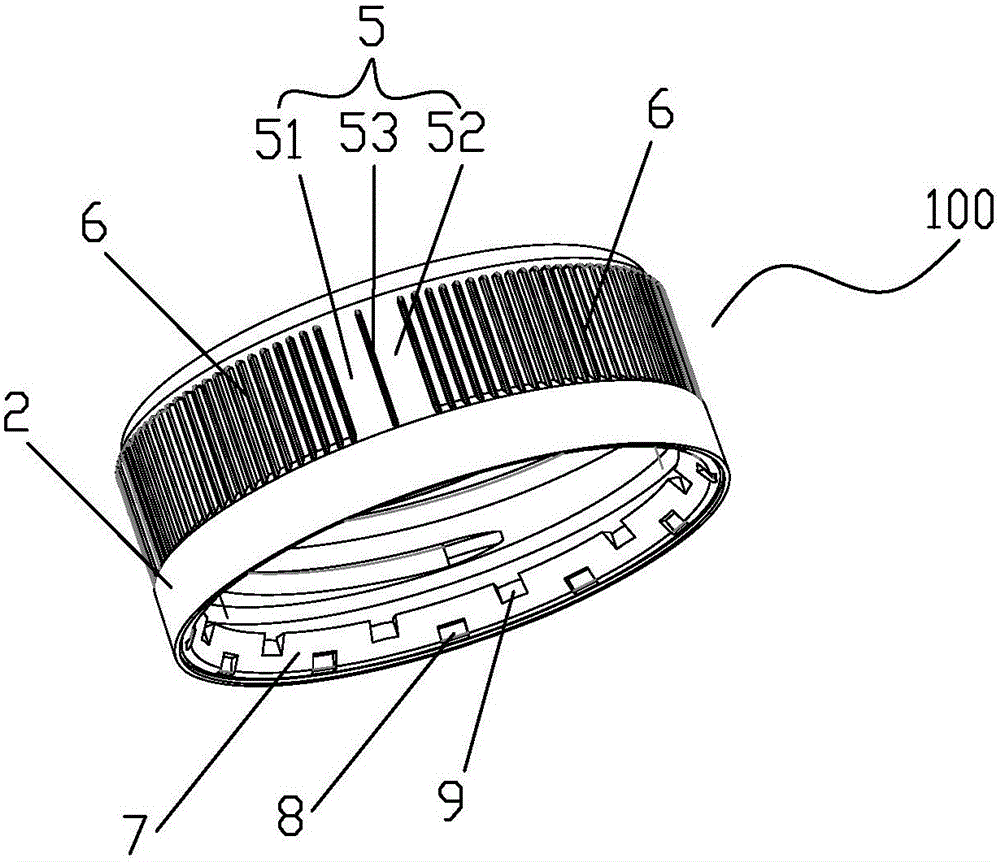

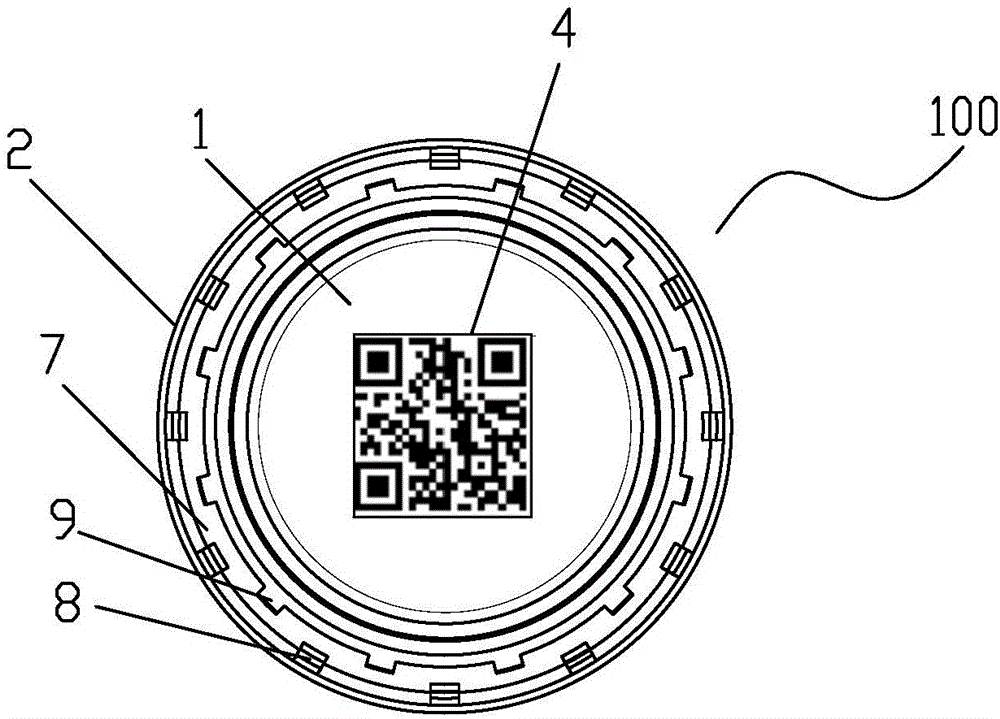

[0028] (2): The laser beam emitted by the laser coding machine 400 next to the laser marking platform 200 directly hits the top sheet 1 of the plastic bottle cap 100, and the top sheet 1 is directly etched into a laser etching layer 4 capable of storing product information , the laser etching layer 4 is an uneven two-dimensional code pattern formed on the top sheet 1 through laser beam etching of the top sheet 1;

[0029] (3) Laser coding machine 400 completes the laser beam etching mark, the mechanical gripper 300 on the laser marking table 200 is separated from the positioning pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com